Up to Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Manual transmission

- Unit: NSG370

- Vehicle Application: Jeep

- Issue: Design

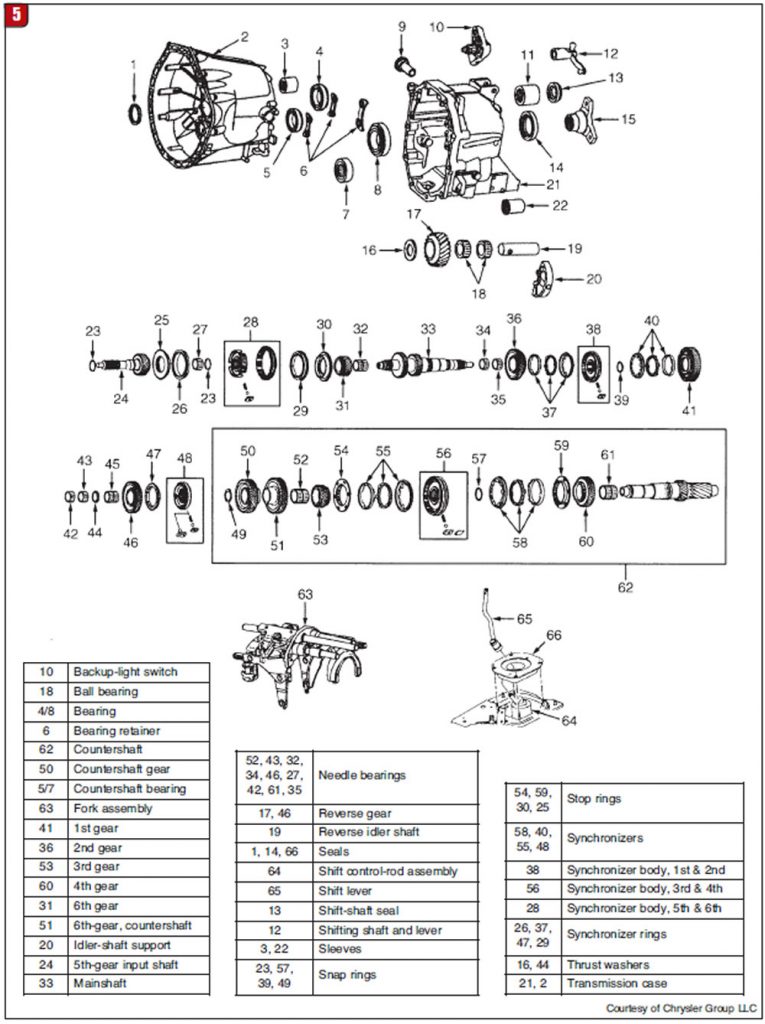

We have seen many changes in the companies that manufacture automobiles. Chrysler got married to Mercedes, the love affair didn’t last and now Chrysler is part of The Fiat Group. While Chrysler was paired with Mercedes, it chose a German-design six-speed for use in Chrysler vehicles. Thus we saw the NSG350, a six-speed manual transmission fitted to 2005-2008 Jeep Liberty, 2005-to-present Wrangler, 2004-2006 Chrysler Crossfire and the 2006-2008 Dodge Nitro, as well as some Mercedes ML models.

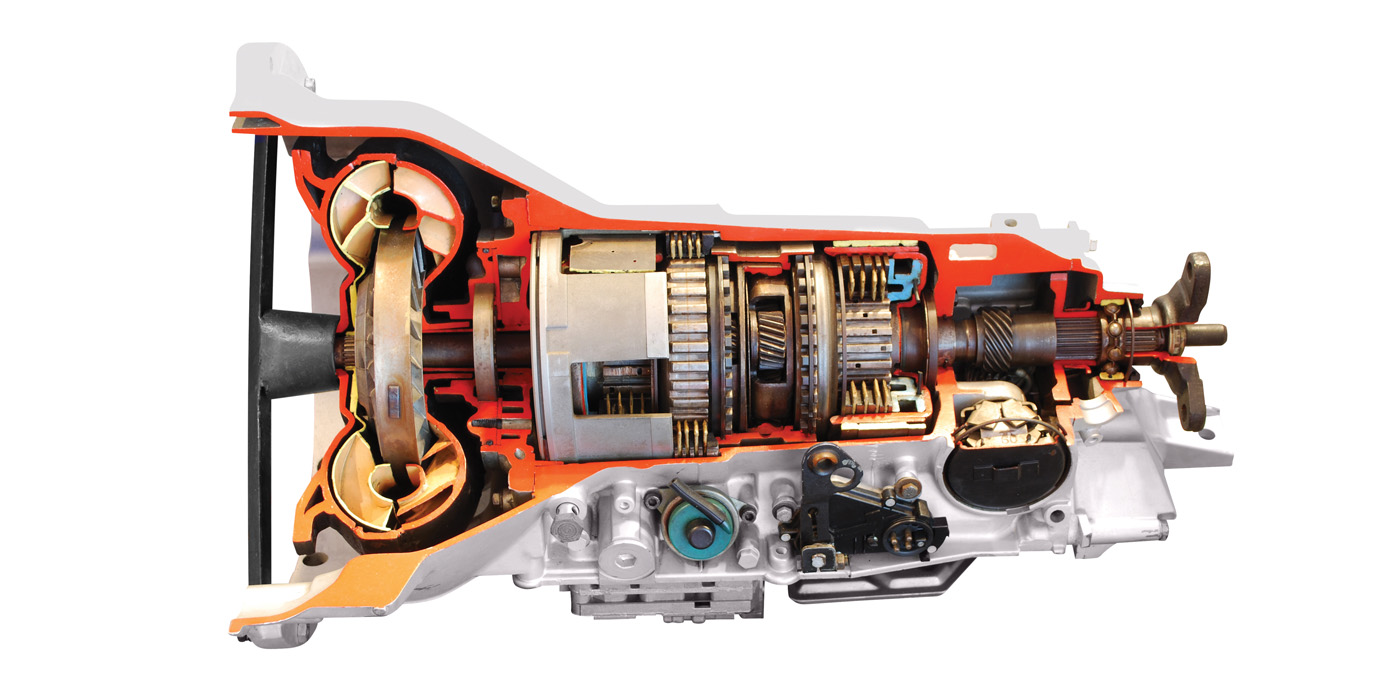

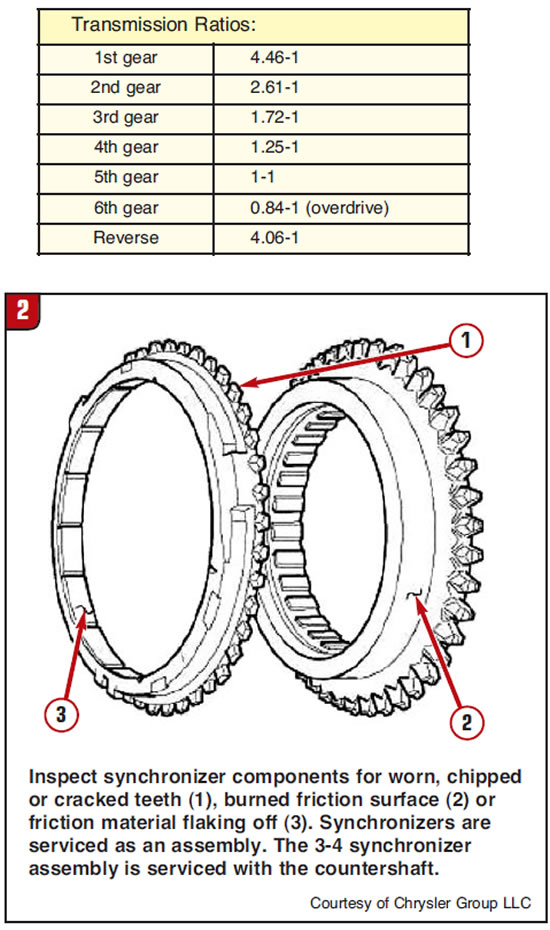

NSG is a German acronym for “new shifting manual transmission,” although you may also say NSG stands for “not so good.” This six-speed manual transmission has an integral bellhousing in the front case and as is common in European design is loaded longitudinally. Fifth gear is 1-1 ratio (direct drive) and sixth is overdriven, so be aware of this when you are diagnosing a problem.

This transmission replaced the NV3550 and NV1500 that had been used in the Jeep line. The 370 is a top-shifted aluminum-case unit with a dry weight of 89 pounds and a torque rating of 272 lb.-ft. There are two front case/bellhousings, which fit either the Mopar 3.7-liter V 6 or the Jeep 4.0-liter inline six.

The clutch release is hydraulic, and the front case has a quill tube to mount the release bearing. The V 6 model is 24.8 inches long, and the 4.0 version measures 23.5 inches with a height of 18 inches. These units will use 33/4 pints of Chrysler spec MS-9224 fluid. RSG synchromesh will work perfectly in these units.

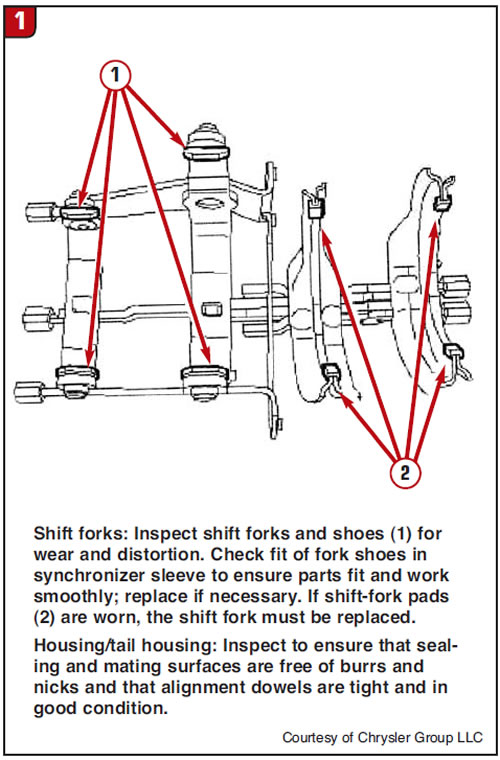

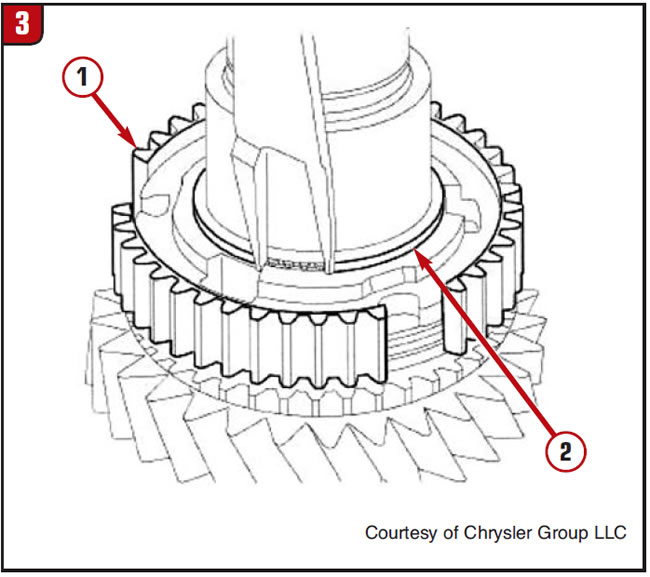

These transmissions are not difficult to work on, but experience tells us that there are weak points in the design. The first of these is the shift-rail system, which is composed of flat steel shift rails similar to those found in some medium- and heavy-duty trucks. The problem here is that the fork pads are a synthetic material that is molded into the steel forks. These wear out and you have to replace the entire rail and fork. Replaceable fork pads would have been a better idea. These forks are also subject to deformation, which can cause a constant gear rattle as the bent fork oscillates on the synchro sliding sleeve.

Another area that creates early wear and failure is the synchronizer engagement teeth on the speed gears, which are very fine and not deep enough. We see continual failures on the Jeep line because of the back taper on the speed gear and synchronizer wearing out, creating gear-hop-out problems, particularly with first and reverse. The problem here is that although this unit works OK in a Crossfire or Mercedes with 26- to 28-inch tires, it is isn’t tough enough for Jeeps with 35-inch tires. The design is good for our industry, as it provides enough work for us, but has some shortcomings for durability.

This unit has some specific points to be aware of when you’re tearing down and rebuilding. Look at the manual, which is available from many online sources such as Mitchell OnDemand, as there are some issues that you need to watch for. Number one is that every snap ring in this unit is SELECTIVE. Mark the snap rings for their location so they can go back the same way. If you lose or break a snap ring use the thickest ring that will fit the groove.

It helps to have the assembly stand to hold the gear train together, as is common with ZF and New Venture designs. The countershaft seal plug and several other seals are not going to be reusable after disassembly. We have had several noise complaints with units after they were remanufactured. Several complaints were due to crankshaft play in the engine that permitted the crankshaft to apply rearward force to the transmission input shaft. Several issues were caused by a worn input gear and headgear from the countershaft. The countershaft head gear (fifth) is removable so that you do not have to buy the whole assembly.

The NSG370 is a good unit for us, and as you get into them you will find the same patterns showing up. Read the manual, get the specs, determine the pitfalls and avoid them, and do well.

Mike Weinberg is president of Rockland Standard Gear.