Up to Standards

- Subject: Design and operation

- Unit: NSG370

- Vehicle Application: 2005-10 Jeep Liberty, 2005-up Jeep Wrangler, 2004-08 Chrysler Crossfire

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

The Jeep brand is one of the iconic names in automotive history. Created as a personnel carrier for the military during World War II, the brand has been owned by several manufacturers over the years and is now part of Chrysler Corp. The use of the original military vehicles by millions of American service members during and after the war created a market for the brand that is still very strong today.

Originally a simple on- and off-road vehicle, Jeep can be credited with bringing millions of customers into the four-wheel-drive market. The late-model Jeep is a luxurious descendent of the simple and, by design, crude military version. Jeeps through the years have been equipped with a great variety of three-, four- and five-speed manual transmissions and a similar variety of transfer cases.

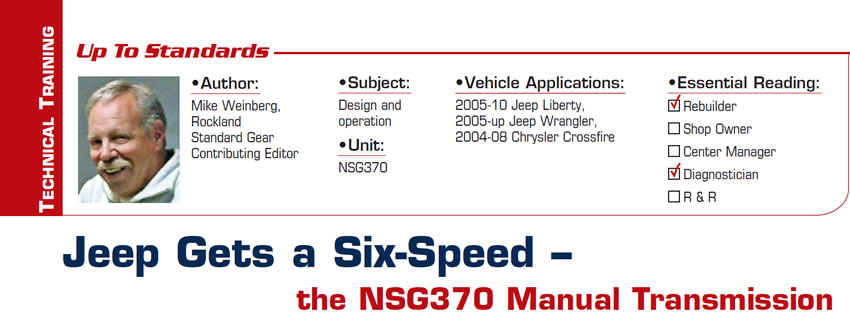

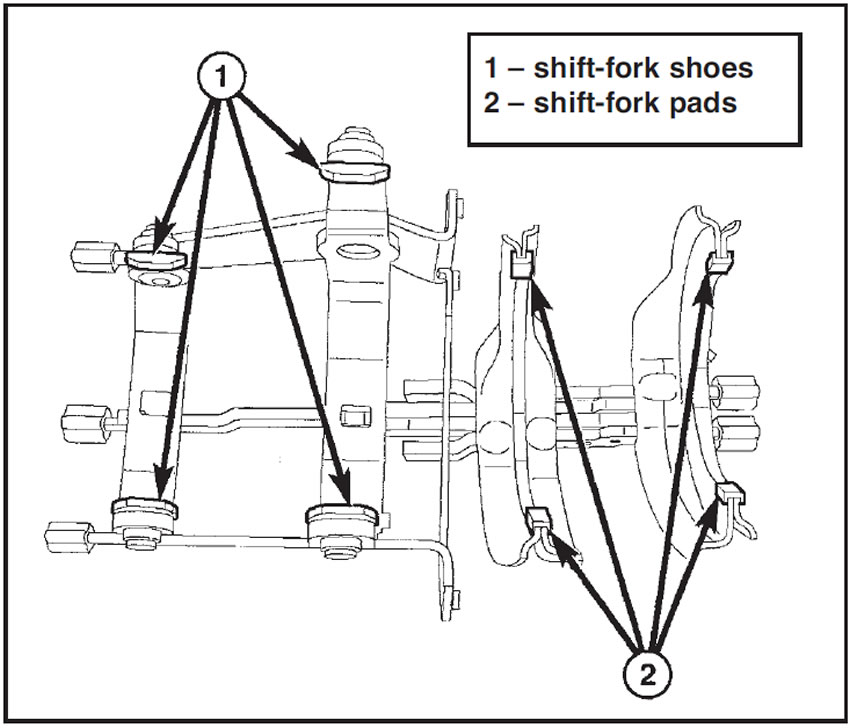

During the ill-fated merger with Daimler Corp., Jeep received a six-speed transmission, the NSG370, which was designed and produced by Daimler. This transmission is available on the 2005-10 Jeep Liberty, 2005-up Jeep Wrangler and 2004-08 Chrysler Crossfire. The NSG370 features a two-piece aluminum case with integral bellhousing and is available with the following ratios:

- 1st gear – 4.46-1

- 2nd gear – 2.61-1

- 3rd gear – 1.72-1

- 4th gear – 1.25-1

- 5th gear – 1.00-1

- 6th gear – 0.84-1

- Reverse – 4.06-1

As you can see, the ratios are a departure from traditional transmission design. First gear is very tall and designed, I assume, as a “granny” gear for off-road adventures, since in normal on-pavement driving you will run out of revs very quickly. Most owners will probably start out normal daily driving in second gear. Reverse is also pretty stout for the same off-road ability. Most six-speed units have fourth gear as direct drive (1-1 ratio), but as in many other German designs, fifth is direct drive and only sixth is overdriven for better highway fuel economy. These units will be found behind three different engines: a 3.7-liter V-6, a 2.4-liter gas engine and a 2.8-liter diesel, ratios being the same for all power plants.

As you may have realized by now there are some basic design and engineering differences between German and American transmissions. The German companies – ZF, Getrag and Mercedes – usually have higher interference-fit levels on bearings and gears. These closer tolerances mean that the amount of force needed to seat a bearing or gear is higher, and these manufacturers all recommend using an electric bearing heater to expand the gears and bearings so that they drop into place freely and tighten on the shafts as they cool.

This means that you need to follow some simple rules to handle the components safely. Bearings and gears should be heated to a minimum to 212° F and a maximum of 350° F. Use only an electrical heater; DO NOT USE A GAS TORCH. Be careful not to overheat the parts, and if you see any discoloration due to overheating replace the part. Make sure you use welding gloves when handling the heated components. Commercial purpose-built bearing and gear heaters are available, but you can use a quality toaster oven that is equipped with a temperature-control setting and a thermometer. This may seem to be a pain in the neck, but you will get used to it and enjoy how easily the heated parts just drop into place with little or no pressing or use of a hammer and installer.

The NSG370 is equipped with sintered-metal synchro rings and uses triple- and double-cone technology to get quality shifts. This also means that you need to use the correct factory lube fill for the proper coefficient of friction in the fluid so that the unit shifts correctly.

There are also a few special tools that make assembly quicker and easier, and they are available from the Chrysler essential-tools catalog. You can build one of these units without the assembly stand, but it will take two people to install the components in the case. One important fact about these transmissions: Every snap ring in these units is select fit. It is a good policy to mark each snap ring as to location or wire it to the component it retains for reassembly. If you get them mixed up or lose one, make sure to use the thickest snap ring that will fit.

As of this writing there is no aftermarket source of supply for the NSG370 parts, so the dealer is the only source I know of. If the volume levels increase, the aftermarket will tool up to create a source of parts. The gear train and other components are pricey, so make sure you do a thorough teardown and inspection and price all the parts needed to the customer.

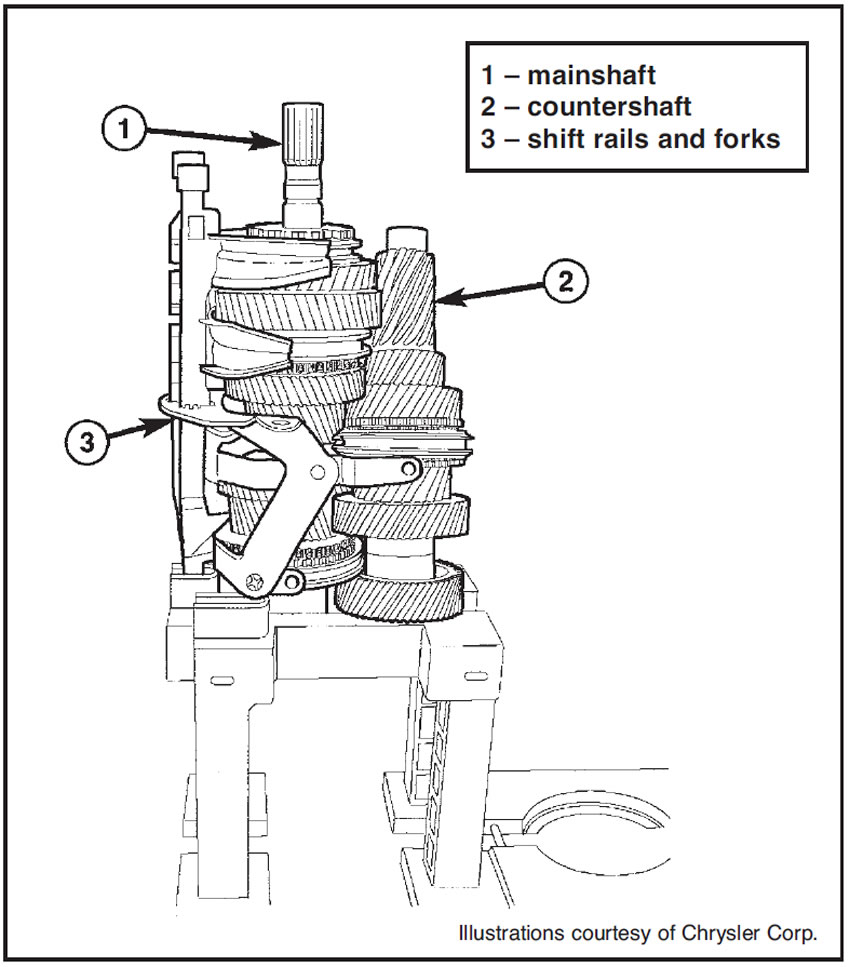

For instance, the countershaft (#62 in the exploded view) sells as an assembly, and that assembly lists for $1,260. The most-commonly failed parts we have seen are the shift-fork assembly, on which the molded fork pads wear to the point of failure. The fork assembly (#63) lists for $330. Another common wear point is the reverse synchronizer and reverse gear. From experience this is an area that is always subjected to driver abuse. Most people are in a great hurry to get into reverse and will make that shift with the vehicle rolling forward slightly. This puts the weight of the moving vehicle onto the reverse synchronizer slider and the reverse speed gear. The pointing on the engagement teeth is very fine, and it doesn’t take much to round off the teeth and burr up the slider. To prevent warranty issues caused by bad driving, you need to explain to your customer that the only time to shift to reverse is with the vehicle at a complete stop.

This design takes a little getting used to, but rebuilding these will become easier as you see more of them. Jeeps’ being among the few vehicles besides muscle and sports cars in which people still enjoy shifting gears themselves and traveling off road should provide our shops with more work in the future.