The very first automobiles needed a way to transmit power to the wheels. Early methods of accomplishing this were comprised of exposed belts and pulleys, effectively creating a single-speed transmission. There were many different variations, but to get both acceleration and speed, more than one gear was needed. It wasn’t long before multiple-gear setups were invented.

The next step was enclosing multiple gears in a sealed case, which effectively became the first true manual transmission in the context we think of them today. These first units were non-synchronized, meaning when you shifted gears, you had to match the speed of the input, or driven gear, to the speed of the output gear. Since the speed of the input gear was directly related to the speed of the engine, you did this by adjusting the throttle to attain the matching speed and shifting the gears at just the right moment. Shifting was no picnic, and often a noisy and difficult process.

The affect that different-sized gears have on acceleration and speed is easy to understand (think different-size sprockets on a bicycle), making this type of manual transmission a natural first step of evolution. Surprisingly, one of the lowest rungs on the evolutionary ladder is the planetary gearset, which is normally associated with an automatic transmission (a much later invention) instead of a manual.

I think it’s always fun to look at planetary gearsets, and in this case, it also makes evolution a much more interesting topic, since they play such an integral part.

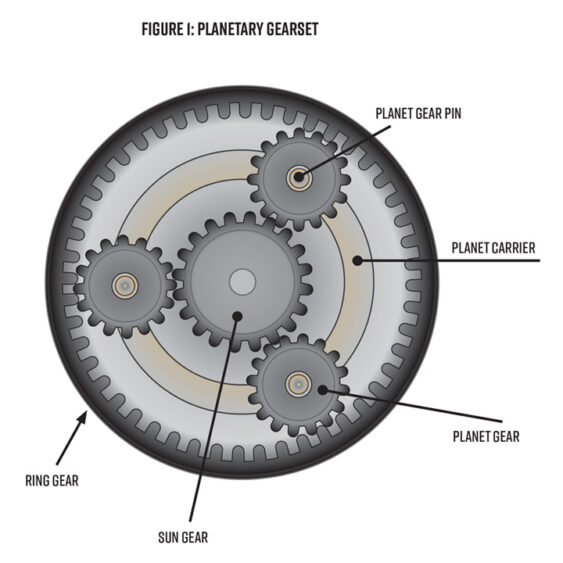

The planetary gearset was somewhat of an engineering marvel. It’s a set of gears (see Figure 1) whose name only makes sense when you see what they look like. The fascinating part about a planetary gearset is its ability to provide different gear ratios as well as reversing direction based upon the specific components that are held or driven. Note that the planet gears are mounted and rotate on pins that are affixed to the planet carrier.

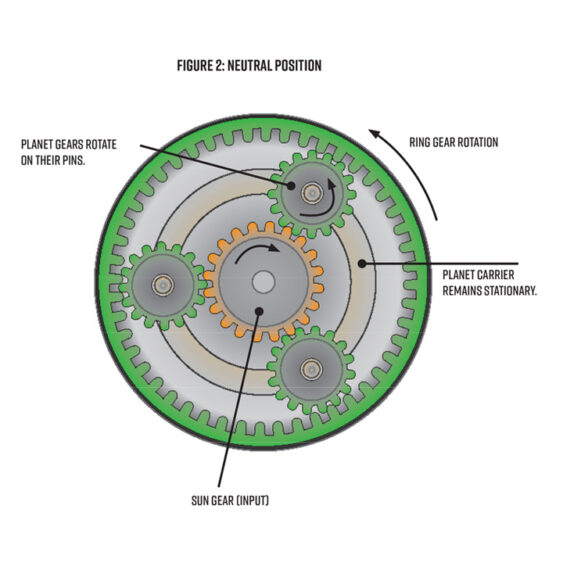

Figure 2 shows the action of the gearset in a neutral position. The sun gear is the input for the gearset. As the sun gear rotates, it transfers motion into the planet gears. As the planet gears rotate on their pins, they in turn transfer motion into the ring gear. The input is from the sun gear, but since the ring gear isn’t engaged to anything for this position, there is no output.

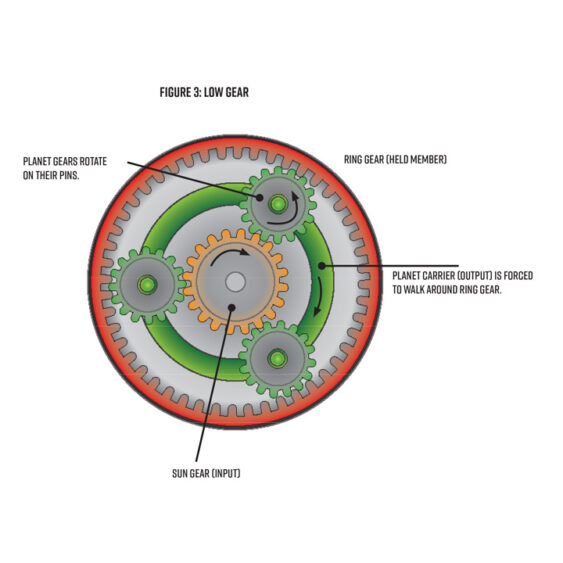

Figure 3 shows the action of the gearset in low gear. The ring gear is held stationary, and the sun gear is the input. Power transfers from the sun gear into the planet gears. The planet gears rotate on their pins, but since the ring gear is held, the planet gears are forced to “walk” around the ring gear, which causes the planet carrier to turn. The planet carrier is utilized as the output.

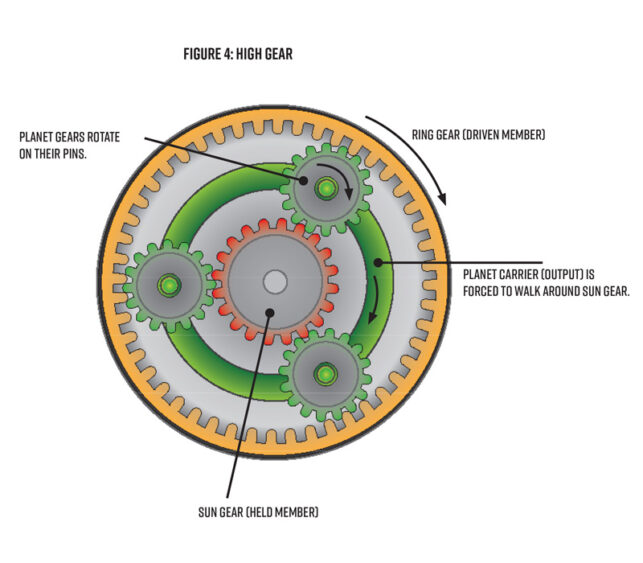

Figure 4 shows the action of the gearset in high gear. The ring gear is the input, and the sun gear is held. The ring gear transfers motion into the planet gears, which rotate on their pins. Since the sun gear is held, the planet gears are forced to “walk” around the sun gear, which causes the planet carrier to turn. The planet carrier is the output, but at a higher speed than in Figure 3.

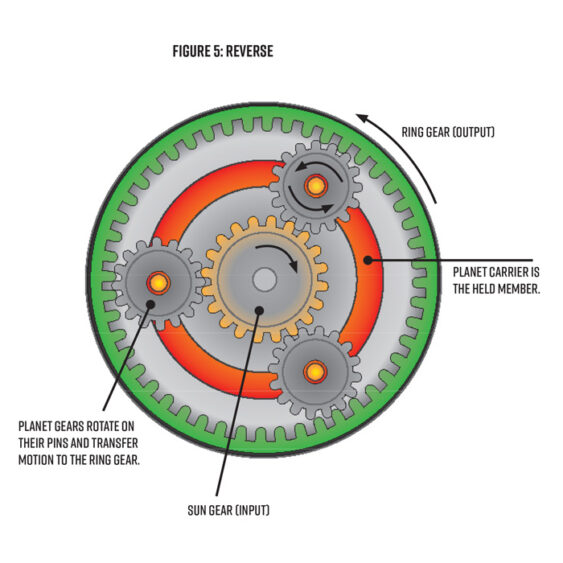

Figure 5 shows the action of the gearset in reverse. The sun gear is the input, and the planet carrier is held. The planet gears rotate on their pins, and motion is transferred from the sun gear to the planet gears, then to the ring gear. The ring gear is the output.

The key to making a planetary gearset work is the ability to hold and drive different components of it at different times. And in order to expand the capabilities of different gear ratios, multiple gearsets can be used together, referred to as compound planetary gearsets. I think you might see where we’re going, but first let’s get back to evolution.

If only it was that easy

The easiest thing to say would be: The manual transmission was first and the automatic came second. End of article. Well, that’s true… sort of. The earliest “transmissions” were a way of transmitting power from the engine to the wheels. Then came the first non-synchronized multiple-gear manual transmissions. But shifting was a chore, and thanks to the planetary gearset, there was another style of transmission to join the game.

This new transmission utilized the advantages of a planetary gearset for multiple forward speeds, neutral and reverse. And it utilized “brake bands” for holding the various members of the gearset to obtain the desired output. Planetary gearsets and brake bands, again, are almost always immediately associated with automatic transmissions, but this was a manual transmission.

It was shifted through the use of levers and pedals, and proficiency took practice, but gone was the grinding and fighting associated with an unsynchronized gear-type of manual. Though not the first to utilize the design, the first mass-produced automobile to use this type of transmission was, well, the first mass-produced automobile: the Ford Model T.

It was very successful for many years, but certain design aspects such as the band linings being made of cotton or wood weren’t destined for the future. By the time the Model T was ready to step down in 1927, the “traditional” manual transmission with gears lined up along the mainshaft and coupled to an input through a countershaft had become the “standard” type of transmission in almost every automobile.

Most of them were still unsynchronized at this point, but gear and shifter design as well as throttle control had improved considerably, making them much easier to shift, and then came a huge evolutionary leap with the development of the synchromesh manual transmission in the late 1920s. These transmissions utilized a synchronizer between second and third gears (most transmissions of the time had only three speeds) primarily to aid down shifting. With the clutch disengaged, the synchronizer was able to match the speed of the input shaft to that of the output, allowing the driver to easily shift gears with no noise or grinding. To shift into first or reverse, the car had to be stopped.

Unrivaled in performance and durability, the manual transmission remained the standard for the automotive industry for many decades, and the early 1950s brought the development of the first unit with all forward gears fully synchronized. Three-speed manual transmissions were the most common, with four-speeds usually only optioned on performance-oriented cars. In the 1980s, most manual transmissions were either four or five speeds, and eventually production cars saw as high as seven-speed manual transmissions.

Manual transmissions were coupled to the engine through a clutch – a purely mechanical friction device that allowed the driver to slowly engage the engine to the transmission, in order to get the vehicle moving without stalling the engine. Clutch control was achieved primarily through mechanical linkages, but eventually cables offered a more efficient alternative, and finally hydraulically controlled clutches proved to be the smoothest and easiest

to operate.

The planets finally align

Undoubtedly a cosmic event for the motoring public, by the late 1930s, technology was ready for the planetary gearset once again, and they were back for good in the first mass-production automatic transmission: the GM Hydramatic four-speed. Many automatic designs and attempts preceded it, but this design and the use of hydraulic fluid not only proved successful and dependable, but also set the bar for the future of automatic transmissions.

Compound planetary gearsets were controlled by brake bands and clutch packs to control the automatic shifting and gear ratios, and a fluid coupling was the more notable aspect that eliminated the need for a clutch and made driving easier. A fluid coupling utilizes an impeller and turbine housed together in a sealed unit. Fluid is pumped into it and as it spins, the impeller (fixed to the engine) throws the liquid into the blades of the turbine (fixed to the transmission input), causing them to rotate. To visualize this, picture what happens when you spray a direct stream of water onto a fan blade: It rotates.

A fluid coupling provides the ability to transfer the power from the engine into the transmission, yet at low speeds it will slip, allowing the vehicle to be stopped and remain in gear without stalling

the engine.

As the automatic transmission itself evolved, the standard fluid coupling was replaced by the torque converter. The difference and advantage of a torque converter is that it has an additional component installed – the stator – which redirects the flow of the fluid exiting the turbine into the direction that the impeller is already spinning, effectively increasing the torque that’s transferred into the transmission.

Cruising along

OK, so now the automobile is cruising right along through the decades of the 20th century with manual transmissions being “standard” equipment and automatic transmissions always an additional cost option. All of a sudden, we have emissions and fuel-economy regulations, and we have to start squeezing efficiency out of every inch of an automobile.

Torque converters don’t initially have the ability for a direct coupling, so there’s an efficiency loss in their operation. “Lock-up” converters are developed to physically connect the impeller and turbine above a certain speed, eliminating any loss.

Computers and electronics hone automatic transmission shifting and efficiency into an art form, and now we’ll see as many as eight speeds. The automatic transmission has become so popular, efficient and dependable that manual transmissions have almost completely disappeared from availability on new cars. The automatic transmission is now the new “standard.”

Continuing evolution

A continuously variable transmission (CVT) is one that operates exactly as the name would indicate and is able to provide changing gear ratios in a smooth, continuous operation. Gaining popularity in the auto industry in the 1990s, CVTs actually have been around longer than the automobile in multiple different industries, and used by many early automakers as well. But they didn’t see popular widespread use in this industry until the 1990s.

There are multiple different designs, from pulleys and belts/chains to discs and rollers. The basic idea of operation is the relationship of conical-shaped pulleys and the point at which they drive or are driven.

CVTs have the advantage of smooth operation, and their ability to constantly adjust gear ratios allows them to keep engine rpm lower during operation, which adds to fuel economy. They are traditionally less expensive to manufacture because they have fewer components than an automatic transmission.

The automatic manual

Direct-shift gearboxes (DSG) also are referred to as dual-clutch transmissions (DCT) and often mistakenly called automatic transmissions by vehicle owners and salespeople alike. A DSG internally is a manual transmission with gears and synchronizers that we’ve been familiar with for years. The difference, however, is that they have two clutches and two input shafts – one set for odd-numbered gears, one for even-numbered gears.

Clutch and internal gear changing is generally controlled by servos (there’s no clutch pedal or traditional linkage-style of shifter), which in turn are commanded to operate through the logic of an electronic control unit that responds to inputs from a slew of sensors and switches. When driving in one gear, the transmission already has shifted into the next gear, but the clutch for that corresponding mainshaft is disengaged. At the point when shifting occurs, that clutch engages as the other simultaneously disengages, and the process continues in this manner.

The advantage of this type of transmission is that it can shift much quicker than any other transmission, and they provide better fuel economy by eliminating any slippage or lag time associated with an automatic. They also are extremely popular for performance and racing due to their quick, precise shifting, which means quicker acceleration and no driver error. Shifting can be controlled by a driver in manual mode, or the vehicle can simply be placed in automatic mode.

When these transmissions first came out, they were frequently misrepresented as automatic transmissions, because with no clutch pedal and a shifter that looked like a traditional automatic shifter, it was easy not to know the difference. There are some characteristics such as the feel of a downshift that tell you it’s a manual transmission, and as a technician, I spent a lot of time explaining that nothing was wrong with somebody’s “automatic” transmission, and it felt the way it did because it wasn’t really an automatic.

Oddballs

Over the years, there have been a few oddball transmission concepts in the evolutionary chain. For example, a lesser-known model was Volkswagen’s AutoStick, which was available from 1969 to 1976. It was a manual transmission with a vacuum-operated clutch servo that disengaged the clutch when a hand was placed on the shifter. It also had a torque converter installed, so even with the clutch engaged, the engine would idle in gear.

And here’s another one: From 1984 to 1988, the Chevrolet Corvette featured a 4+3 manual transmission, which was a basic four-speed manual with an overdrive unit on the end. When driving the car in second, third or fourth gears, if you let off the gas, it would automatically engage the overdrive in the interest of saving gas. My own personal thought: It was just weird, and a little annoying.

Nicknames

Over the years, many transmissions have earned nicknames, lovingly or otherwise. Manual transmissions were referred to by the number of gears they had. For example, some called a three- or four-speed “three- or four-gear” transmissions. They also were often simply called “standards,” because they were the standard for many years. They’re also commonly called “stick shifts,” and in the early days, often referred to as “crash boxes” due to the noise they made shifting because of the non-synchronized gears. Specific models like the Muncie M-22 with straight-cut gears earned the name “rock crusher” because of the loud noise from the gears. Today, manual transmissions have become so uncommon that fewer people learn to drive them, and they’re often referred to as a “millennial anti-theft device.”

Automatics didn’t get as many names, but the most common was “slushbox,” due to their characteristics of slow shifting, which today’s technology has eliminated. Regardless of the number of speeds, if you had an automatic, you still just had an automatic.

I hate to say it, but in many ways, this is only scratching the surface of transmission evolution. Probably the most important factor in all of it is that transmission fluid has evolved right alongside it, and it’s more critical than ever to only use the correct fluid that’s specified for each and every transmission, regardless of what it is.

This article originally appeared in the pages of TD’s sister publication, Counterman. All images were created by Eric Garbe.