Up To Standards

- Author: Mike Weinberg

One of the difficult problems facing most transmission shops is the identification of manual transmissions. To be able to order parts and create a valid sales quote for a customer, the shops have to know what they are working on. Stick-shift transmissions comprise about 20% of the market; so most shops are very familiar with automatic units and have difficulty with manual-trans identification. The following guide provides some basic information to lead you in the right direction as to which transmission you are working on. Space limitations do not allow us to list every manual transmission you may encounter, but those listed here are the most-common units in domestic trucks and sport/utility vehicles.

Identifying manual transmissions requires great care. Many units have the same design externally but have different ratios to work with various engines. Obviously, a transmission with ratios for a 2.3-liter 4-cylinder engine will not be durable if used with a V-8. Manual transmissions designed for gasoline engines will have poor drivability if used with a diesel engine, and vice versa.

A real-world nightmare occurs when you encounter a vehicle that has had a repair involving a junkyard swap. The only problem is that they put the wrong unit in and the customer is now in your shop to get it repaired correctly. In a typical scenario all ID tags are gone from the unit. If you order parts to repair the unit that is in the vehicle you can fix it but the ratios will be wrong for the vehicle. This is why tooth counts, bearing numbers and case casting numbers are extremely important not only to order parts but also to ensure that this is the right unit for the engine/chassis combination you are repairing. We have seen countless instances in which shops have fixed a unit correctly only to have it fail quickly because someone had put a 4-cylinder unit in a V-8 application. When working on standards, try to obtain as much information as you can and preserve all ID tags with the unit.

Four-Speed Transmissions

T170 Series

T170F (Code-RUG)

Side-mounted overdrive (SMOD). Synchronized in all forward gears, with top-loaded cast-iron case. Used in 1978-84 Ford light-duty pickups and vans. Similar in appearance to the Ford “top loader trans” but has overdrive 4th gear. Three shift rails mounted to the left side of case. This unit was produced for cars also but with lighter-duty bearings and geartrain. Produced in 2- and 4-wheel-drive versions.

T170FS (Code-RUG)

Also known as single-rail overdrive (SROD). Has an aluminum case with shifter turret on extension housing. Synchronized in all forward speeds, with 4th being overdrive. Used in Ford light-duty pickups 1980-83. There is also a passenger-car version of this unit with lighter-duty bearings and gear ratios. Produced in 2- and 4-wheel-drive versions.

T170FT (Code-RTS)

Top-loaded unit with 4th being overdrive. Aluminum case and shift tower. Found in Ford F-150/250 light-duty trucks 1984-85. Also known as a TOD (top-shift overdrive). Produced in 2- and 4-wheel-drive versions.

New Process A833

All forward speeds synchronized. Manufactured in both direct-drive and overdrive models. 10-bolt shift cover on left side of case. Early models had iron cases, and late-model cases are aluminum. Case length measures 105⁄8 inches. Used in Chrysler passenger cars 1964-80, Dodge trucks 1976-85, and General Motors trucks 1981-86. GM models may be identified as RPO code MY6. Produced in 2- and 4-wheel-drive versions

New Process 435

Top loaded heavy-duty unit with cast-iron case and extension housing and aluminum shift tower. 2nd through 4th gears are synchronized, with 1st and reverse using non-synchronized sliding gear. Found in 1963-85 Dodge trucks, 1964-85 Ford pickups and stripped chassis, 1964-72 GM trucks, and 1964-85 International Harvester and Navistar trucks. Produced in both 2- and 4-wheel-drive versions.

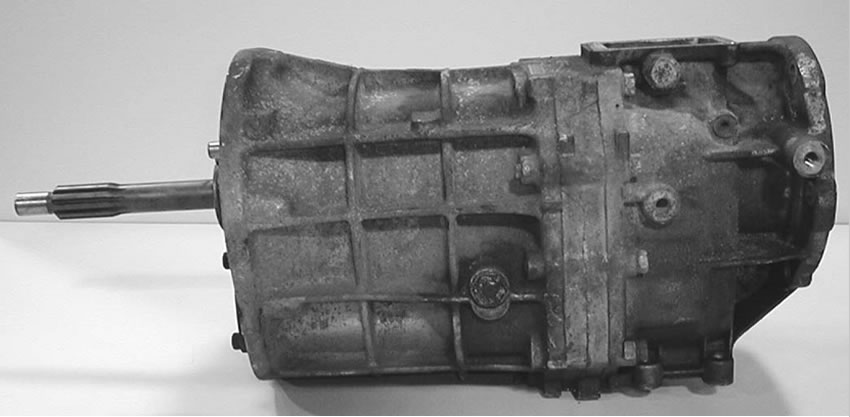

Muncie SM465

(shown without extension housing)

Top-loaded heavy-duty unit with cast-iron case, extension housing and shift tower. Synchronized in 2nd, 3rd and 4th. Available in 2WD and 4WD versions. Cases have PTO openings on both sides. 1st and reverse are non-synchronized. 1st gear is a deep-reduction low gear, and shift knob may show H pattern with Low, 2, 3, 4. Used in GMC and Chevy trucks and stripped chassis 1968-85.

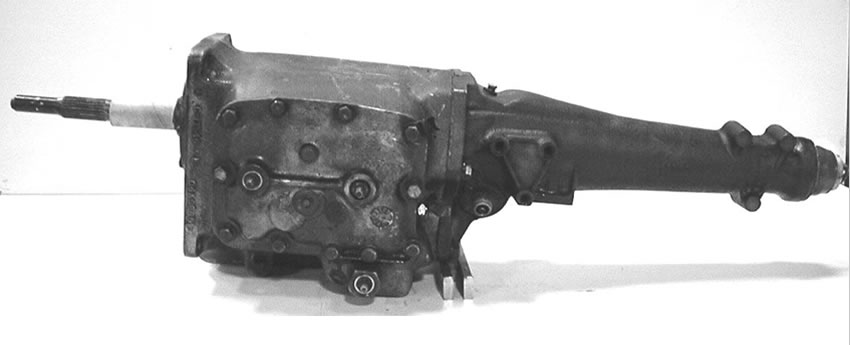

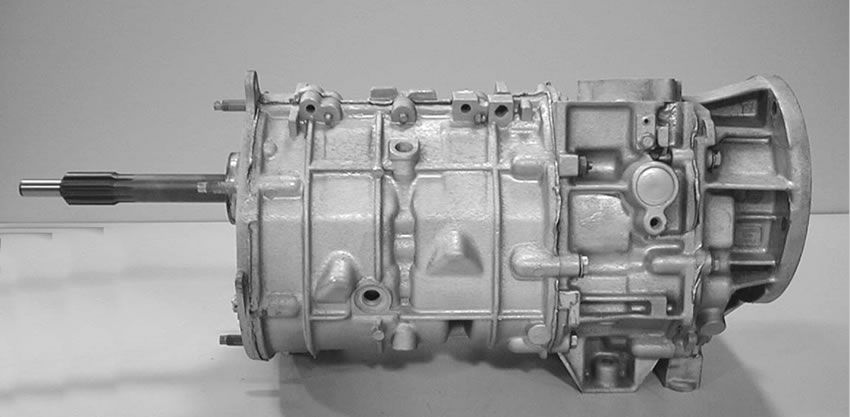

Borg Warner T18

(shown without extension housing)

Top-loaded heavy-duty unit with cast-iron case and shift cover. Case casting number is 1301. Synchronized in 2nd, 3rd, and 4th, with 1st and reverse non-synchronized. Available in 2WD and 4WD versions. Easily confused with earlier BW T98 and T98A models. Use care when ordering parts to make positive ID of unit. Used in Ford trucks 1956-73, Jeep models 1965-85 and International 1965-73.

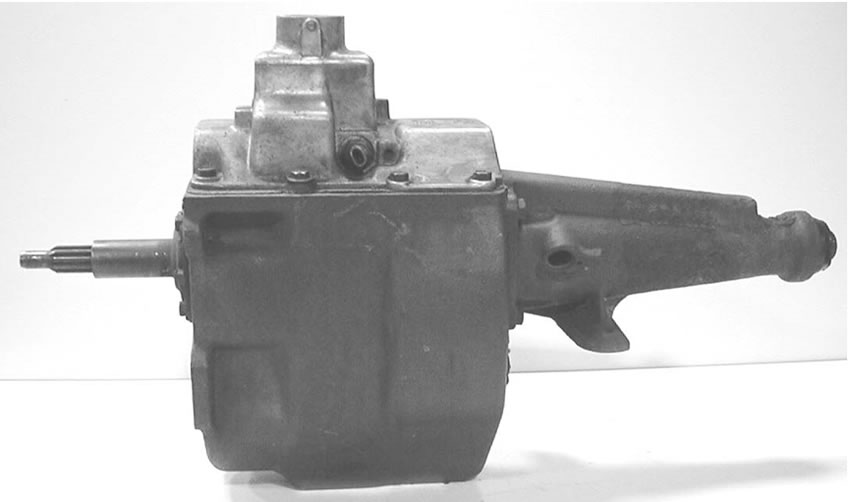

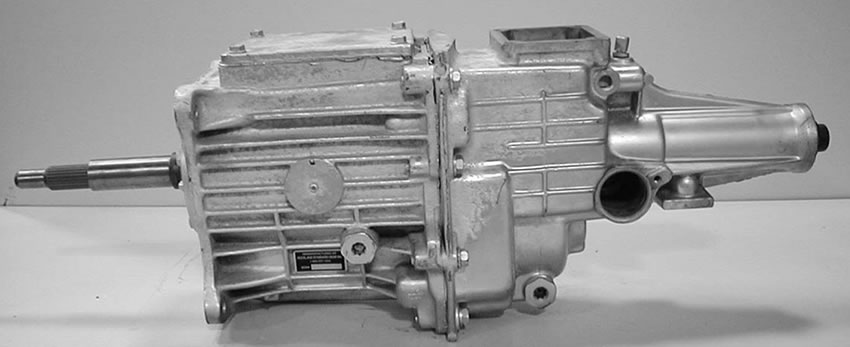

Borg Warner T19

(shown without extension housing)

Top-loaded heavy-duty unit with cast-iron case and shift cover. Case casting number is 1309. Easily confused with T18, but the T19 is synchronized in all forward speeds. The T19 has a single-step reverse idler gear; the T18 has a 2-step reverse idler. Available in 2WD and 4WD models. Used in Ford trucks 1974-85 and International trucks 1974-85.

Five-Speed Transmissions

Aisin Warner AX5

Fully synchronized center-support unit with aluminum case and extension housing. Available in 2WD and 4WD models, and with external and internal hydraulic slave cylinders. Used in Jeep vehicles 1984-up with gas engines and 1984-87 with diesel power.

Aisin Warner AX15

Fully synchronized center-support unit with aluminum case and extension housing. Similar in appearance to AX5 but larger with heavier-duty geartrain. Available in 2WD and 4WD configurations. Used in Jeep vehicles 1990-up and Dodge Dakota trucks 1992-up.

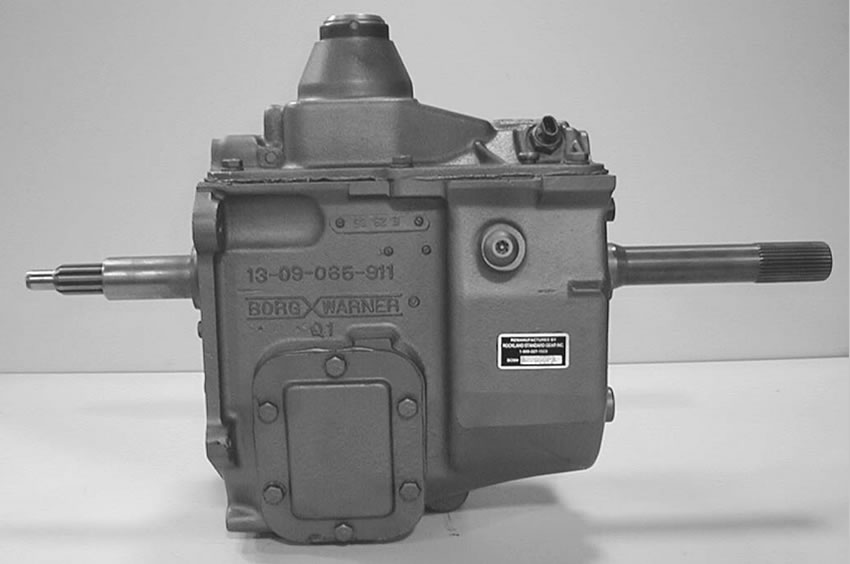

Borg Warner T5

All-aluminum top-loader. All forward gears synchronized. Early design has brass synchronizer rings; later “world-class design” uses paper-lined rings and tapered bearings on countershaft. Model number on ID tag attached to extension-housing bolt starts with 1352. Built in 2WD and 4WD versions. Used in Jeeps 1982-87, General Motors S10 2WD trucks with mechanical speedometer, GM S10 1989-95 with electronic speedometer, and GM 4×4 S10 1983-95. Also found in Astro Vans with 2.8 or 4.3 V-6 engines. Tremec Corp. bought the design from BorgWarner and now manufactures this unit.

Peugeot BA10 (AX18)

Light-duty aluminum unit available in 2WD and 4WD models. “Suitcase” design whereby the main case splits apart lengthwise for disassembly. Used in 1987-89 Jeep vehicles with 4.0-liter engines. Note location of shifter and how it’s retained, as there are two designs. Additionally, there are 5- or 6-bolt mounting flanges for the transfer case on 4WD models.

New Process 2500 (New Venture 535)

Light-duty, fully synchronized 5-speed center-support unit with aluminum case and 4-bolt top cover. Available in 2WD and 4WD models. Shifter is behind top cover on top of transmission.

FM145

Fully synchronized in all forward gears. Available in 4WD only. Bellhousing, case and extension housing are aluminum, with removable bellhousing. Extension housing measures 101⁄2 inches, and there is a 12-bolt steel bottom pan. Manufactured by Mitsubishi and used in Ford Ranger and Bronco II vehicles 1985-89. Red ID tag on left side of case gives Ford part number and unit serial number.

FM146

Synchronized in all gears (including reverse). Built in 4WD version only. Used with open dummy transfer case in 2WD vehicles. Aluminum bellhousing, case and extension housing, with removable bellhousing. Extension housing is 13 inches long, and there is a 12-bolt steel bottom pan. Manufactured by Mitsubishi and used on Ford Ranger and Bronco II vehicles 1988-92. Red ID tag on left side of case shows Ford part number and unit serial number.

D50

D50 is a common industry name describing a series of Mitsubishi-manufactured 4- and 5-speed units used in Dodge and Mitsubishi small trucks. Models include KM131 4-speed used in Dodge D50 trucks 1983-85; KM132 5-speed, 2WD unit used in Dodge D50 trucks 1983-up; and KM145 5-speed, 4WD unit used in Dodge D50 trucks 1983 to present. These same transmissions also are found in Mitsubishi trucks. Units are similar in design to FM146 except that bellhousing is integral to main case. There are many design levels of this unit, and getting tooth counts and input-bearing numbers before ordering parts is extremely important. There should be a model number and alphanumeric code stamped on the bellhousing to help identify the units.

New Venture 1500

Fully synchronized unit with bellhousing integral to aluminum case. Similar in design and appearance to HM290, 5LM60 and NV3500-series transmissions, but slightly smaller. Requires some special tools to rebuild. Used in 1996-up GM S10 vehicles with 4-cylinder or 2.8-liter V-6.

NV3500

Fully synchronized unit with bellhousing integral to aluminum case. There are four design levels of this unit. It started life in 1988 as an HM290 in GM trucks and was re-designated 5LM60 with early and late designs. HM290 and 5LM60 units have 4 shift rails. The unit was completely redesigned as a 3500 with a single shift rail. Because of design variations, you must positively identify which model trans you are working on to get the right parts. This series, built in both 2WD and 4WD versions, requires some special tools for rebuilding. These units are used in full-size GM trucks 1988- up, S10 trucks 1990-up and Dodge Dakota V-8 Ram trucks 1994-up.

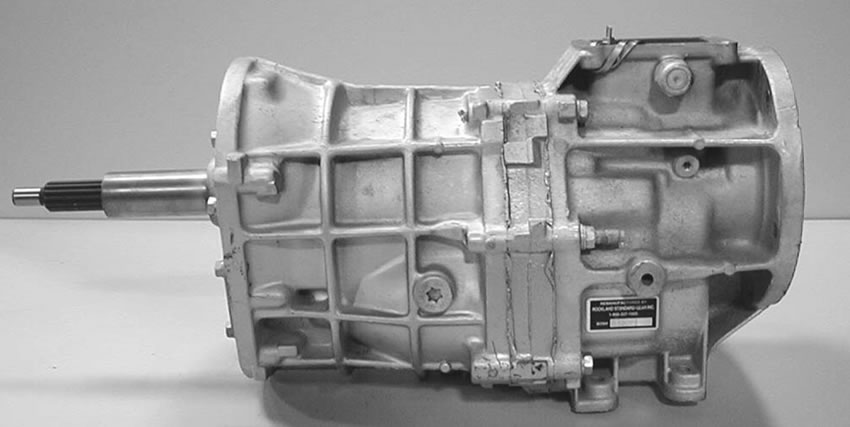

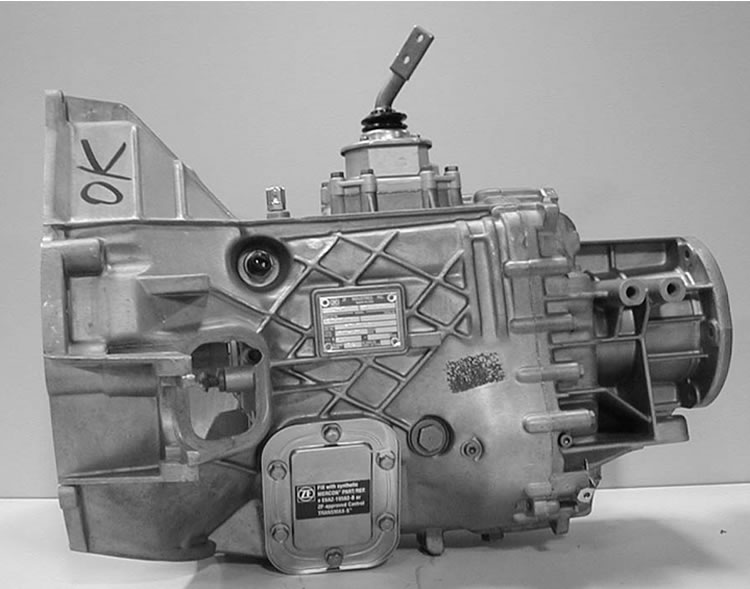

NV4500

Fully synchronized top-loaded heavy-duty unit. Cast-iron case and extension housing with aluminum shift cover. Unit weighs 200 lbs. Found in GM full-size trucks and stripped chassis ’92-up and Dodge V-8 trucks 1994-up. A 4500HD model is used in 1994-up Dodge trucks behind the V-10 diesel engine. This unit MUST use Castrol Syntorque Fluid for lubrication fill.

Getrag G360

(no picture available)

Heavy-duty, fully synchronized unit with cast-iron case and aluminum shift cover. Used in Dodge trucks 1989-93 behind Cummins diesel engine. Because of design limitations and extreme expense of repair parts, you will do the customer a favor by arranging to replace this unit with an NV4500, which has much greater durability.

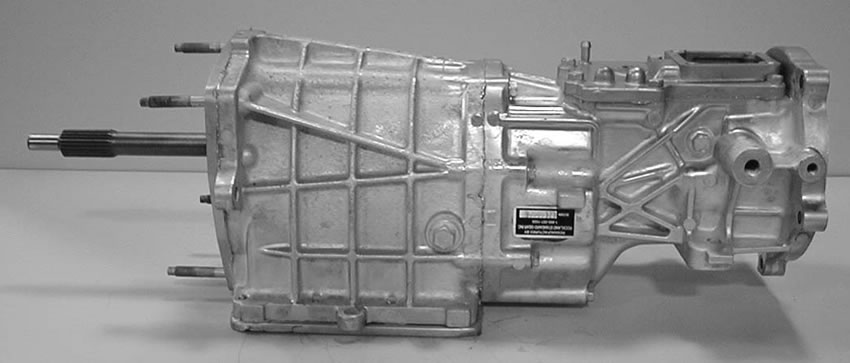

M5R1

Mazda-built fully synchronized unit used in 1988-to-present Ford Ranger and Explorer trucks. Aluminum case with integral bellhousing, aluminum extension housing and aluminum shift cover. Available in 2WD and 4WD models. ID decal on left side of case. Modifications in 1995 made the shift cover taller and eliminated the neutral-position switch in the cover. In 1998 the stub stick in shift cover was changed to accept shift lever with groove on right side. Used with 2.3L, 2.9L, 3.0L and 4.0L engines. Ratios and starter locations on bellhousing vary with engine size.

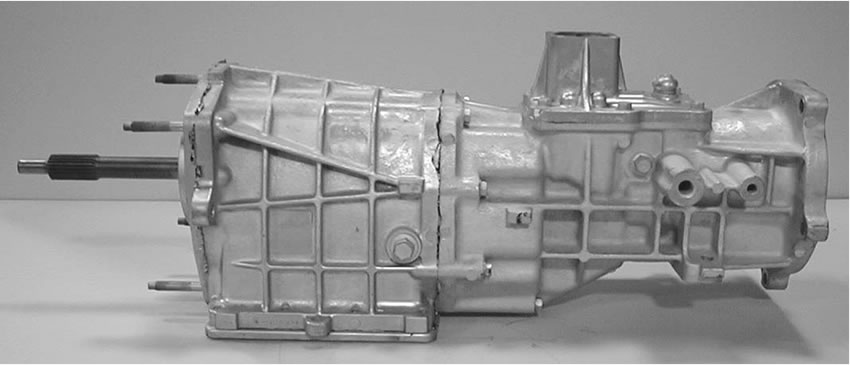

M5R2

Mazda-built fully synchronized unit found in 1988-to-present Ford F-150 series trucks and full-size Broncos. Aluminum case, extension housing and shift cover, with integral bellhousing. Similar in design to M5R1 but larger, with shift lever in center of shift cover. Available in 2WD and 4WD versions. 1995 and later models have top-cover reverse-light switch moved to forward corner of shift cover. In 1996, case was changed to accommodate modular engine (4.6L), with starter-bolt pattern being triangular. In 1999 the case was changed for 4.2L 4WD vehicles. The case is very similar to earlier-style units, with case length shorter on 4.6L and 4.2L models.

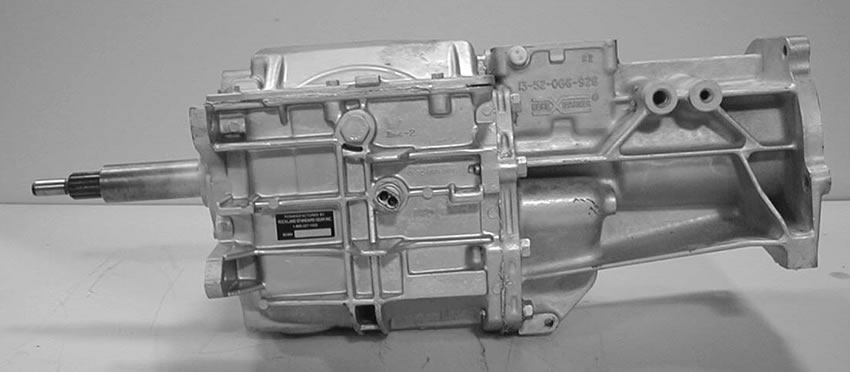

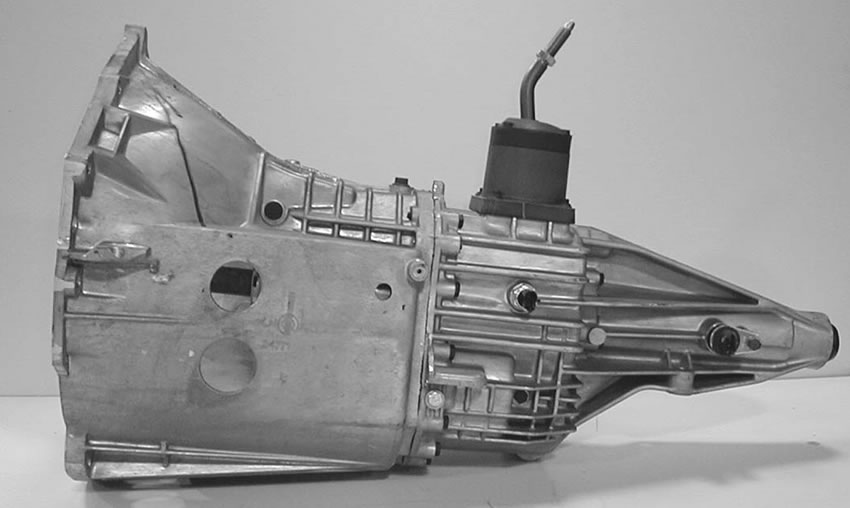

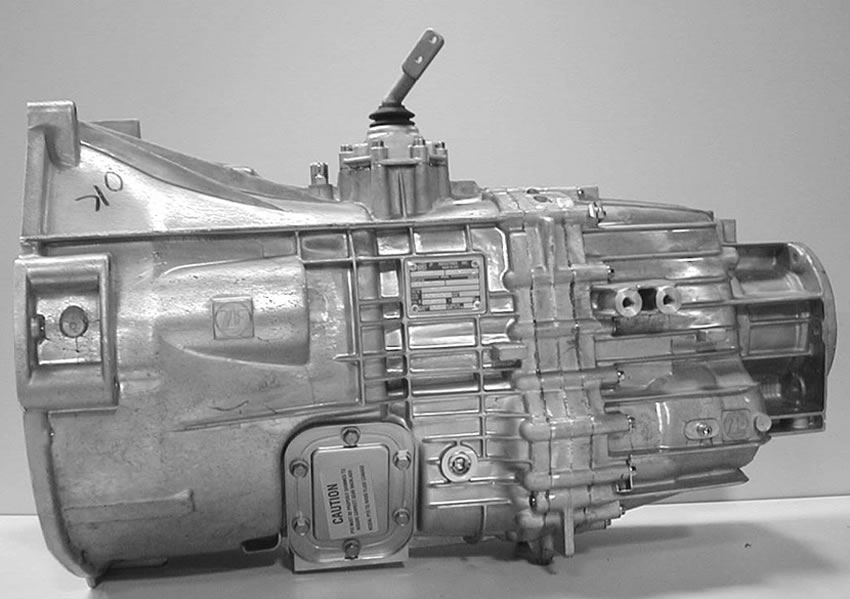

ZF S542 and S547

The S542 is a heavy-duty, fully synchronized unit with aluminum case and extension housing. Bellhousing is integral to case. Shifter is mounted to small shift cover on top of unit. Built in 2WD and 4WD versions. Used in Ford F-250/350/450 and Super duty trucks 1987-94. Super Duty model has mechanical park-brake assembly attached to extension housing. S542 is used behind 300, 302, 351, 460 and diesel powerplants. S547 is used behind the same engines 1995 to present. Both units have PTO covers on each side of case. ID tag on left side of case gives Ford part number, ZF part number and unit serial number. Take great care to properly identify the unit you are working on, as both the S542 and S547 appear to be the same, and with the great variety of ratios available it is easy to order incorrect parts.

NV3550

Light-duty, fully synchronized. Case and extension housing are aluminum, with removable bellhousing. Used in 2000- up Jeep wrangler vehicles with 6-cylinder engines.

Six-Speed Transmissions

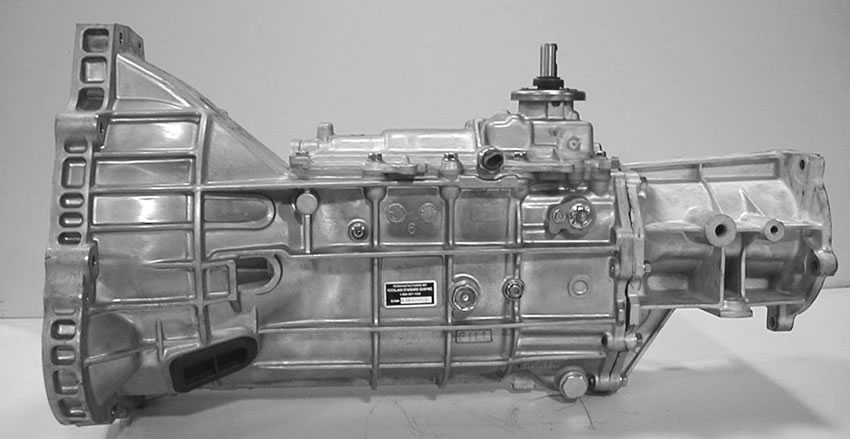

ZF S650

An extremely heavy-duty unit with all gears synchronized. Has an aluminum case with integral bellhousing, a center support and rear case. Built in both 2WD and 4WD versions. S650 is used in diesel-powered 1998-up Ford Super Duty and stripped chassis up to gross combined weight of 26,000 lbs. The unit weighs 230 lbs. The internal oil pump driven off the front of the countershaft to circulate lube to a trans cooler is a unique feature. An easy way to identify this unit is by the cooling lines attached to the case as in automatic transmissions. ID tags are on the left side of the main case.

NV5600

Very heavy-duty unit with all forward speeds fully synchronized is used in heavy-duty Dodge trucks 1998-up. Has an aluminum bellhousing and a cast-iron case and extension housing, with top-mounted shifter. Available in both 2WD and 4WD versions, this unit weighs 360 lbs. Can handle vehicles with gross combined weight of 26,000 lbs.