Manual gearboxes have become much less common in vehicles over the past few decades. The automatic shift transmission became popular—and later dominant—during the 1960s. And, as sure as thunder follows lightning, the business of repairing manual units has decreased steadily as there are fewer of them. Once considered more fuel efficient, manuals have, over time, been surpassed in efficiency by the advanced technology of the modern automatic step transmission as well as the less common CVT and DCT.

Further, there is the nomenclature: Sticks, standards and manuals are terms that are used somewhat interchangeably. More accurately, manual transmissions are any of those that require the driver to manually shift gears in a vehicle. So, both sticks and standards are manual transmissions. Sticks and standards are, to a large extent, opposites. The “standard” transmission refers to what vehicle manufacturers considered standard equipment in the early days of the automatic transmission. The automatic was an upgrade over the standard “three on the tree” manual transmission. The stick shift, famously the “four on the floor,” generally takes the shift mechanism off the steering column and places it on the floor or the center floor console of the vehicle.

It was notable when last year a study found that among cars and light trucks, there were more electric and hybrid electric vehicle production units being manufactured than those with factory manual transmissions. Beyond some pickup trucks, the current model year features a number of European and Asian imports with manual transmissions as standard or optional. Domestically, there are Chevrolet’s Spark and Camaro, the Dodge Challenger, Jeep Gladiator and Wrangler and Ford’s Bronco and Mustang with available manual shifting.

When Transmission Digest began its annual survey of transmission shops in the early to mid 1980s, most shops still found a significant demand for manual repairs. In fact, at that time there were more shops that didn’t work on import nameplate automatics than shops that refused to repair manuals.

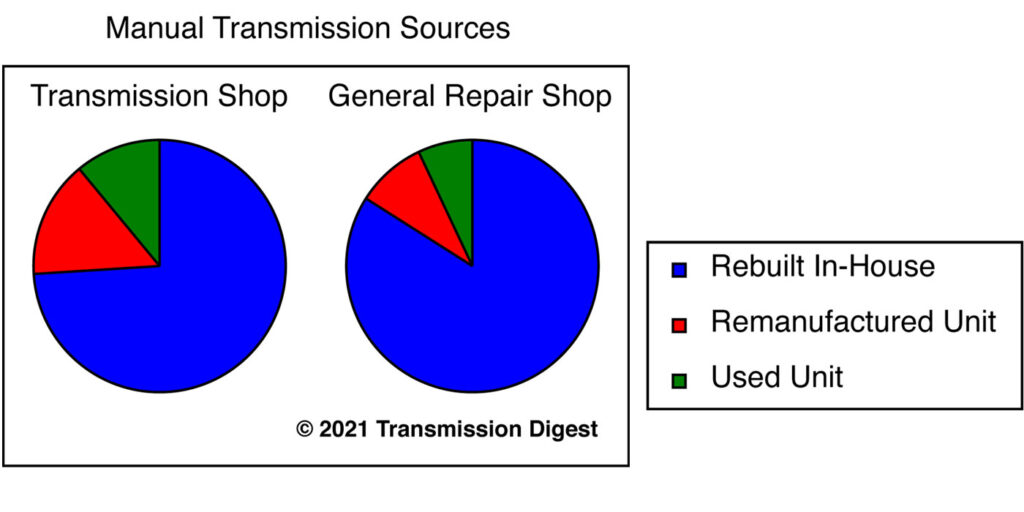

Today, our continuing shop studies indicate that roughly 5% of the work in shops subscribing to the magazine involves repairs beyond clutch work on manual transmission units. For transmission specialty shops offering manual transmission repair, 82% of those jobs are rebuilt in-house while the remaining jobs are remove and replace with a reman or a used unit.

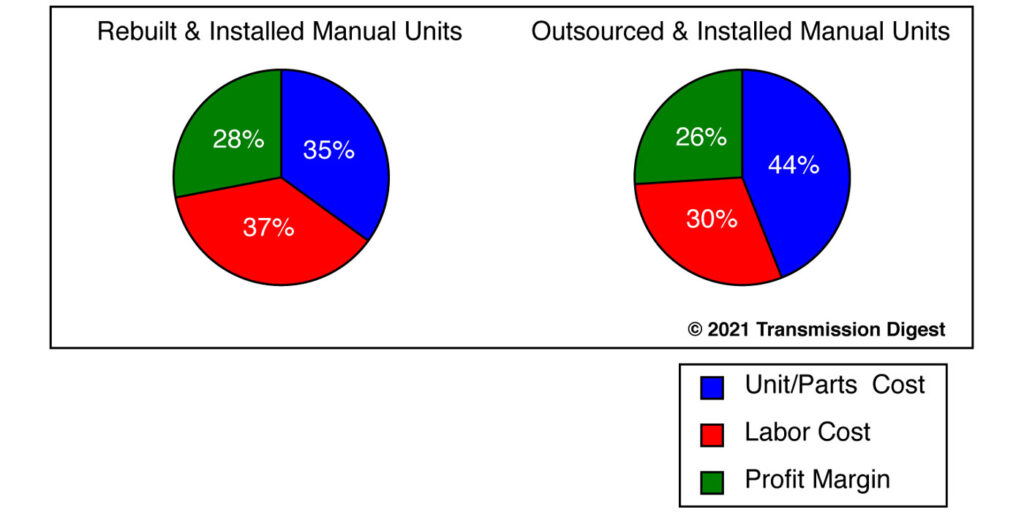

According to the most recent survey numbers (March ’21), the profit margin for in-house rebuilding of manual units is equal, within the margin of error to similar R&R jobs. We find, as would be expected, that labor cost is greater for an in-house rebuild. Acquiring a reman unit is more expensive than the purchase of parts for rebuilding and so the two offset each other resulting in margins between 25-30%.