R&R Tech

- Author: Jerry Huerter

- Subject Matter: Diagnosis

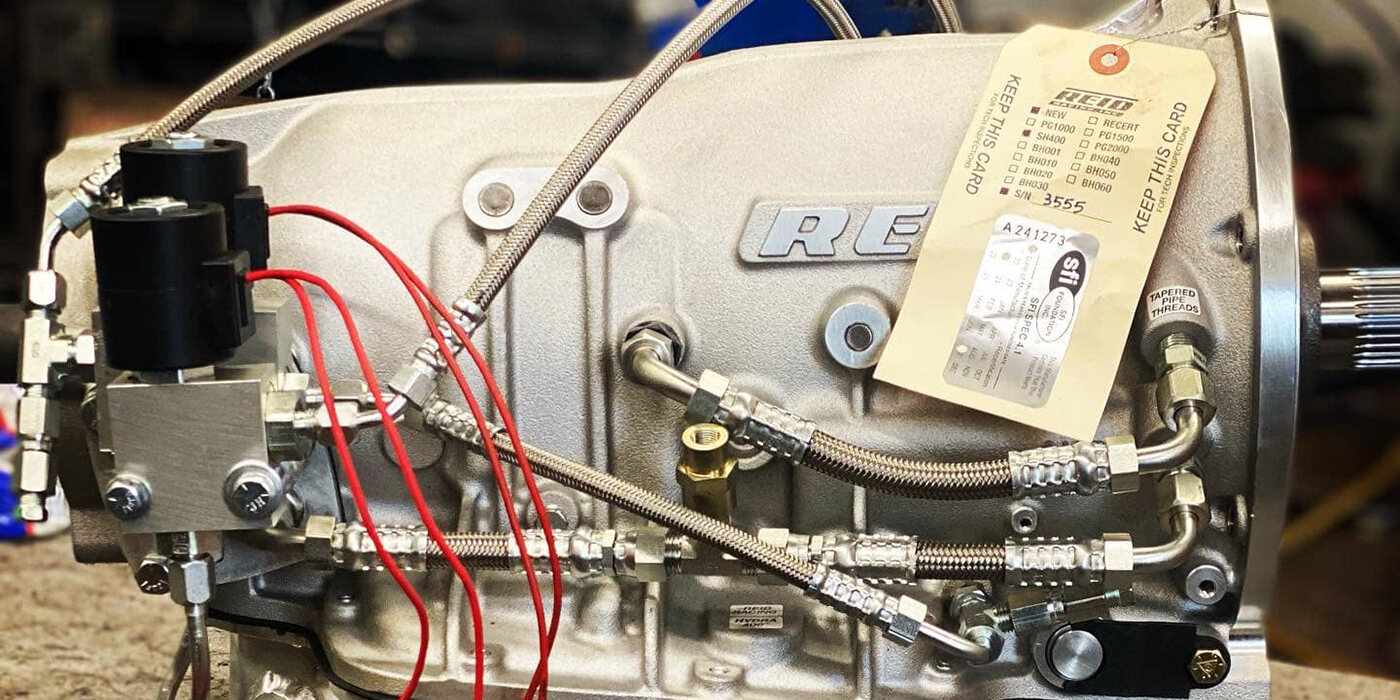

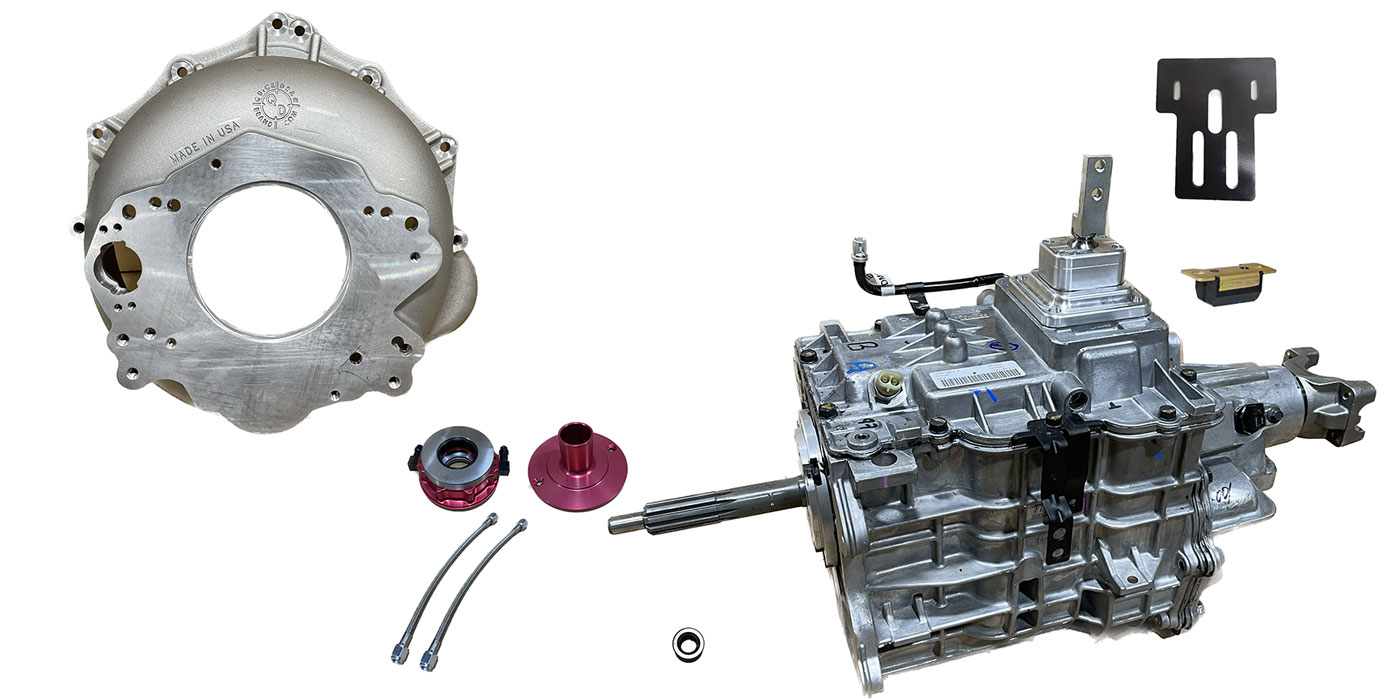

- Unit: 4L80-E

- Vehicle Application: 1995 Chevrolet K1500, 6.5 diesel

- Issue: Multiple transmission codes

Our story begins with a 1995 Chevrolet K1500 with a 6.5-liter diesel and a 4L80 E transmission that was brought into our shop by one of our wholesale customers. The customer had replaced the transmission in this vehicle with one of our remanufactured units. After the installation, the customer said the check engine light came on and the vehicle was setting multiple transmission codes, and that when the truck was going around a left-hand turn the transmission would neutralize.

I began my diagnosis by checking the fluid level and scanning for codes. The fluid level checked OK. Upon scanning the system I found four transmission codes: 72, output-speed sensor; 83, torque-converter quad driver module; 82, shift solenoid “A” circuit; and 81, shift solenoid “B” circuit. I then cleared all codes to prepare to take the vehicle for a test drive.

After the codes were cleared and the engine turned off, the solenoid codes would immediately reset. When the engine was started, the communication between the scan tool and the PCM would be lost. Even though there were codes set and no communication with the PCM, I decided to go for a test drive.

I was expecting second-gear starts and no shifts, but to my surprise the transmission shifted properly through all the gears. Also, I did not experience the neutralizing around the left-hand turn that the customer had complained about. After returning to the shop, I again checked for codes (without the engine running) and found that solenoid codes 82 and 83 were still present and that code 83, torque-converter quad driver module, had returned. On the basis of this information, I suspected PCM failure.

After I replaced the PCM the check engine light went out, and the transmission solenoid codes did not reset.

Problem #1 solved!

However, when I started the engine again the scan tool continued to lose communication with the newly installed PCM. After reviewing the wiring diagram I saw that the airbag module shared the data line with the ECM at the DLC, terminal M. I also noticed that the airbag light was on in the instrument cluster. When I tried to scan the airbag module it would not communicate with the scan tool, either with or without the engine running. Now I was thinking that the airbag module was defective so I removed the fuse, and the scan tool then could communicate with the PCM when the engine was running.

Problem #2 solved!

With the second problem resolved I still hadn’t been able to experience the customer’s complaint regarding the left-hand-turn neutralization. With the scan tool now able to read data, I went for an extended test drive, making as many left-hand turns as possible. As I was making a long, sweeping left-hand turn, the engine flared, the transmission locked into a lower gear and the check engine light came on. The code 72 vehicle speed sensor was set. I cleared the code and again made the same left-hand turn, at the same speed. With the same results as before I confirmed that the left-hand turn was in fact setting code 72. Once more, as I was making the same left-hand turn with a lab scope installed, the VSS signal on the scope would drop out and the transmission would default to second gear.

Now that I had duplicated the customer’s complaint, I knew that during a left-hand turn the VSS circuit was being compromised. Armed with this information I began looking for anything that might be moving or shifting during a left-hand turn. Since the VSS is at the rear of the transfer case, that is where I went to begin tracing the wiring harness. I followed the wiring harness along the left side of the bellhousing, over the fuel-line bracket that was close to the pinch-weld seam of the truck cab. I inspected the wiring harness at the pinch-weld location and found the pinch weld rubbing on the harness. During a left-hand turn the truck cab would shift to the right and ground the VSS circuit. I repaired the wiring harness and rerouted it away from the pinch weld.

Problem #3 solved!

The PCM failure may have been related to the shorted wiring. This case was unique, because there were multiple issues that created a common concern. It also demonstrates the importance of a complete, thorough diagnosis. In this age of the automobile, electronics play a dominant role in the control and wellbeing of our powertrain components, and one issue begets another. In the end, this was a successful repair and the customer left the shop happy.

Jerry Huerter is an ASE certified Master Technician and has more than 35 years of experience in the automotive industry. He is a diagnostician at Certified Transmission’s facility in Overland Park, Kan.