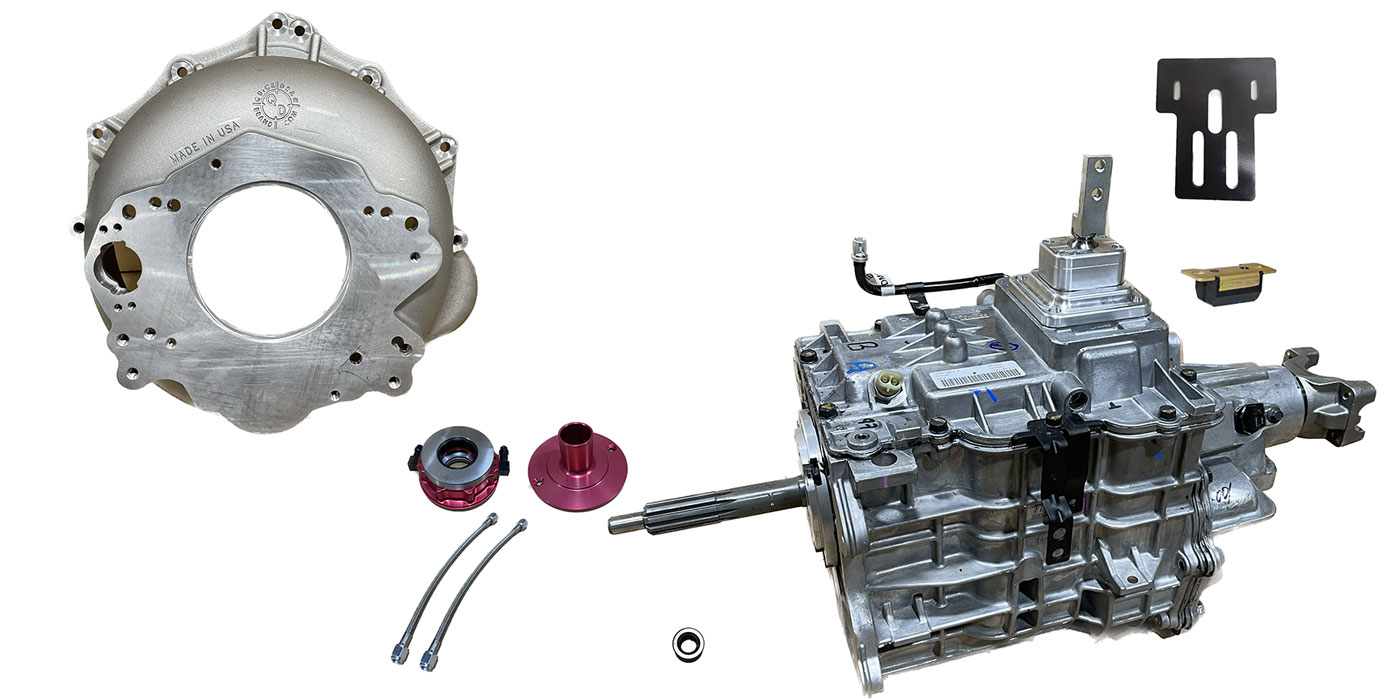

American Powertrain offers Tremec TR-4050 kit for Chevy/GMC trucks

American Powertrain now offers a Tremec 4×2 TR-4050 five-speed Pro-Fit HD manual transmission kit designed for 1988-98 Chevy/GMC OBS light- and medium-duty trucks. The Chevy/GMC OBS 4×2 kit includes a short throw White Lightning Shifter designed for the TR-4050, a crossmember adapter bracket that works with the original factory crossmember, bell housing, hydraulic bearing, pilot

ATI introduces six-speed Chevy transmission performance package

ATI Performance Products has introduced an externally controlled, six-speed transmission package for Chevrolet vehicles. According to the company, the torque converter, bellhousing, transmission and controller all designed to fit and work together with a conventional Chevy or LS-based engine. According to ATI, features and benefits include the following:

TransTec highlights 2014-2018 Chevrolet Impala EPS R&P

TransTec has introduced an electronic rack and pinion seal kit for 2014-2018 model years of the Chevrolet Impala. The company says this EPS R&P kit includes everything technicians need for a complete mechanical repair, including all o-rings, metal clad seals, bushings, and gaskets. This kit is in stock and available for immediate shipment. Vehicle coverage,

Hydramax releases under-dash hydraulic clutch system for Chevrolet C10 trucks

American Powertrain has introduced a new line of Hydramax bolt-in, under-dash Hydraulic Clutch Systems, a kit designed for 1967-1972 Chevy C10 trucks. The kit features an integrated under-dash hydraulic master cylinder and a bolt-in clutch pedal. The included clutch pedal allows for conversion to hydraulic, or an automatic car to manual. The new Hydramax kit

Expect the Unexpected

A 2011 Chevrolet HD2500 6.6L equipped with a LCT1000 transmission came into the shop with a customer concern of no reverse and the indicator under the “R” is flashing.

Blame it on Missing Harness Retaining Clips

The subject vehicle that was fitted with one of our remanufactured transmissions six months prior showed up at one of our repair locations recently, with the customer concern of an intermittent bumpy 1-2 shift, and a low-power lugging sensation along with a CEL on. While performing our initial evaluation, we found a P1860 code stored in history, but not current. During the road test the truck was working well with no clear signs of what set the DTC, but after several minutes of driving it started to act up. The TCC was applying right on top of the 1-2 shift, but according to the scan-tool data, was not being commanded on by the ECU.

Problem or Process?: Surge may be byproduct of ‘displacement on demand’

Recently a 2006 Chevrolet Impala came into one of our retail locations with a surge complaint while cruising on the highway between 60-65 mph. I drove the vehicle with the customer to verify the concern and was able to duplicate the circumstances in which the vehicle acted up. While watching the tachometer I noted that there was a noticeable 150-200 rpm surge while TCC was applied. It felt like a typical TCC surge as a result from a leak in the TCC regulator circuit, so additional diagnostic steps were in order. We discussed this with the customer, and he authorized the additional time. At this point I was fairly convinced that we were going to need to go inside the unit.

Multiple Issues Demonstrate Need for Thorough Diagnosis

Our story begins with a 1995 Chevrolet K1500 with a 6.5-liter diesel and a 4L80 E transmission that was brought into our shop by one of our wholesale customers. The customer had replaced the transmission in this vehicle with one of our remanufactured units. After the installation, the customer said the check engine light came on and the vehicle was setting multiple transmission codes, and that when the truck was going around a left-hand turn the transmission would neutralize.

Basic Visual Checks Key to Successful Diagnosis

We have all read our share of tech articles that end up with the fault being traced to a failed component. We’ve also seen plenty of information about vehicle subsystems creating “false positives” for a component that was incorrectly identified as being bad. Well, this article blends these two scenarios with another added issue: a previous repair by a careless technician.

Aftermarket Accessories Can Be a Sobering Experience

Recently a 2005 Chevrolet Avalanche came into one of our shops with the customer concern of the transmission sticking in one gear intermittently, and the Service Engine warning light illuminating. When I went to start our pre-diagnostic evaluation I grabbed the scan tool and went out to the vehicle, only to notice that it had a “Smart Start” ignition interlock device installed (Figure 1).

At this point I decided to hook up the scan tool and check for codes before driving the vehicle, and I pulled codes P0740, P0753, P0758, P0785 and P2761. On the basis of these codes, we advised the customer that he had an electrical issue and we would need some additional diagnostic time. The customer agreed and left the vehicle with us to diagnose.

Serviceability Report: Chevy Cruze

This is another in a series of reports that asks a simple question: Do the automotive engineers look at “ease of service” when designing a new car?

4L60-E No move after rebuild

The transmission rebuilder accused the R&R man of breaking the pump during the installation process. The R&R man was certain that he had done his job correctly and that the rebuilder must have done something wrong during the rebuild. To help pinpoint the problem, a pressure gauge was installed into the line-pressure port. To everyone’s surprise, the line pressure was normal. This meant that not only was the pump not broken but also the PR valve was not stuck open. This also meant that the transmission would have to be removed from the vehicle and at least partially disassembled.