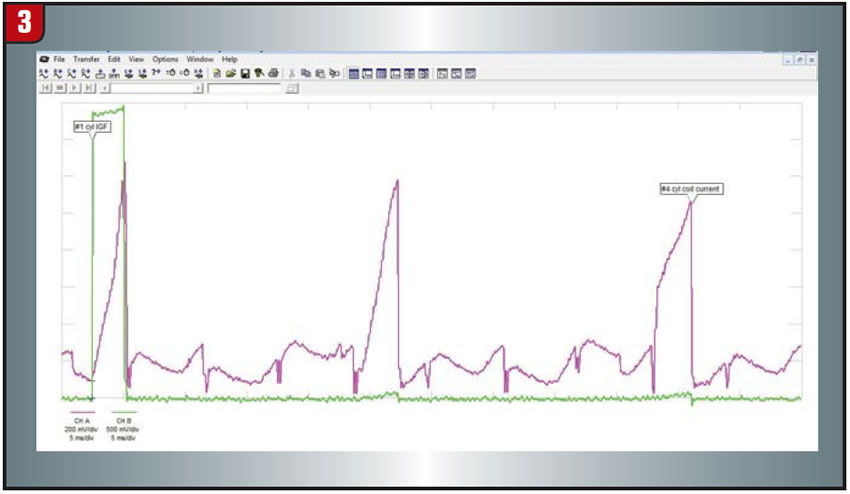

Tech to Tech

- Author: Jeff Bach

- Subject Matter: Drivability

- Vehicle Application: Toyota Prius, Generation 1

- Issue: Engine runs rough

A salvage-title hybrid turns into a workhorse

Recently I picked up a Generation 1 Prius that was listed as flood-damaged at an online auction. I have been buying these types of vehicles and reselling them. I like the Gen 1s because they are like work mules. You can drive them as hard as you want with a load or drive them empty and they run just as well and get nearly the same mileage – loaded or not.

Pluses of hybrids

They have a five-star crash-test safety rating and make great trip cars since they are not tiny lightweights like a lot of econo-boxes I’ve driven. They can get away with putting plenty of sound-deadening insulation in them and heavy carpet because the extra weight translates into extra stored energy. The car uses a motor/generator to do 80% or more of the stopping before the brake pads even touch the rotors.

Since the brakes get used so little, they rarely get replaced as a maintenance item along with the rotors, which seldom if ever warp due to heat as their non-hybrid counterparts do. The gasoline engine is used to power another motor/generator, which supplies the torque as needed along with the high-voltage (HV) battery to get the vehicle moving from a stop – much like the system used in freight trains.

The gas engine gets an easy life because the much-more-efficient three-phase electric motor does most of the work. Hence, these engines seldom wear out even with minimal maintenance. There are plenty of them on the road with more than 300,000 miles on them. Their strong points of superior mileage in stop-and-go traffic and minimal maintenance costs have made them a favorite of taxi drivers and delivery companies in many of the more-progressive cities, especially along both coasts.

Troubleshooting begins

When I got this particular flood car to the shop, it was missing the key so I had one cut from the serial number at a local Toyota dealer just to be able to get the car out of gear and off the cargo trailer. I didn’t expect the car to have any electrical functions since it was coming from New Jersey, and I figured it was a saltwater flood.

I had another Gen 1 that was totaled that I had planned to completely strip as a donor vehicle. I hooked up a jump battery to the vehicle to get it unloaded, and when I turned the key on the whole electrical system came alive like normal. Once I got it unloaded, I pulled it into the shop and hooked it to the scan tool. It had some codes in it, but nothing like I expected. The ignition would turn on but not allow cranking because of the immobilizer system.

Water damage?

Much to my surprise, I was able to get the immobilizer system to work after replacing the original module with a combination module and key from another vehicle. After it was programmed I started the vehicle. This also surprised me. I had checked the fluid levels and inspected the vehicle for evidence of the water to see what the immersion level was. I found no evidence of water anywhere, but the engine ran extremely rough and knocked something awful.

I began to wonder whether possibly the owner got some bad news about an expensive engine repair and turned the car in to the insurance company as flood-damaged. I started to diagnose the engine miss, since the knocking didn’t bother me as I’m used to hearing that sound from a partially running hybrid. It’s a common thing to hear that thrashing when the engine is in a state of spinning over with MG 1 but not producing enough power to start and charge the HV battery. I like to look at the current direction on the DC cables at the HV battery to determine the power output from the internal-combustion engine (ICE). This test told me that it was running enough to produce power; it just had a miss.

Ignition coils testy

I noticed that the engine had new ignition coils. I have had some experience with ignition coils on some other Toyotas’ powertrain systems, which had me curious enough to want to see the ignition trigger (IGT) and ignition fire (IGF) signals on the scope along with the ignition-coil current signal.

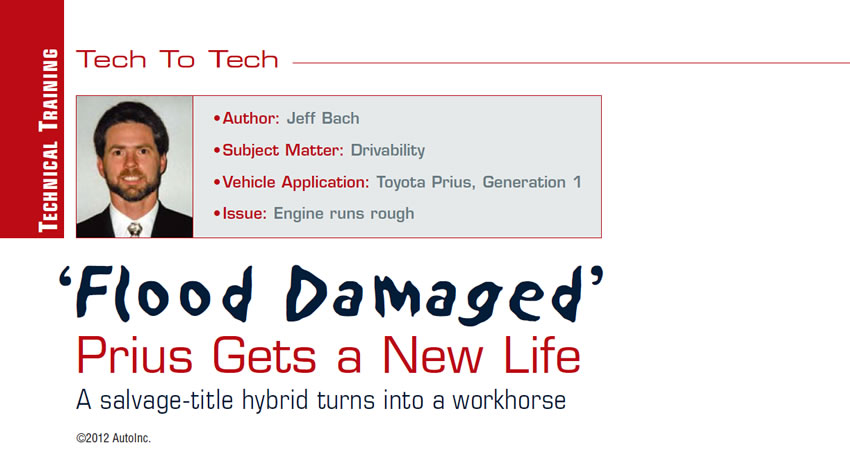

The HV battery was in a low-state-of-charge condition so I needed to let the car run a bit to get some voltage back into it. With the car missing as it was, I figured the injector was shut off to protect the catalytic converter. I looked under to see whether the converter was hot (Figure 1) and realized that the injector for the missing cylinder was likely still operating.

Hard to imagine a one-cylinder miss making this catalyst work so hard oxidizing the fuel from the missing cylinder – and at just an idle.

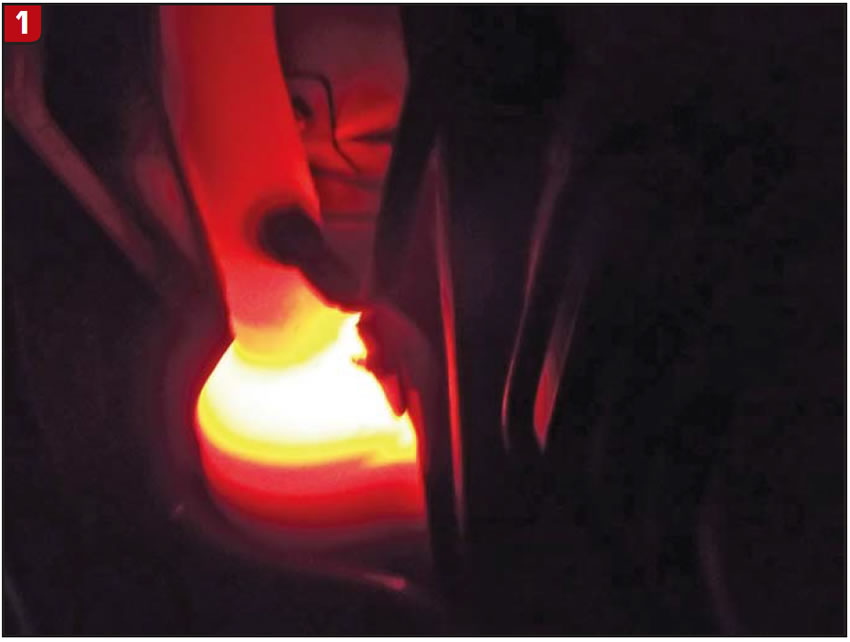

Figure 2 is letting us have a look at the ignition current on the scope’s channel in a parade pattern from the feed circuit at the fuse.

The second channel is showing the IGF signal. Viewing the ignition current even at this scope speed looks suspect. Blowing the pattern up and looking at each coil tells a better tale.

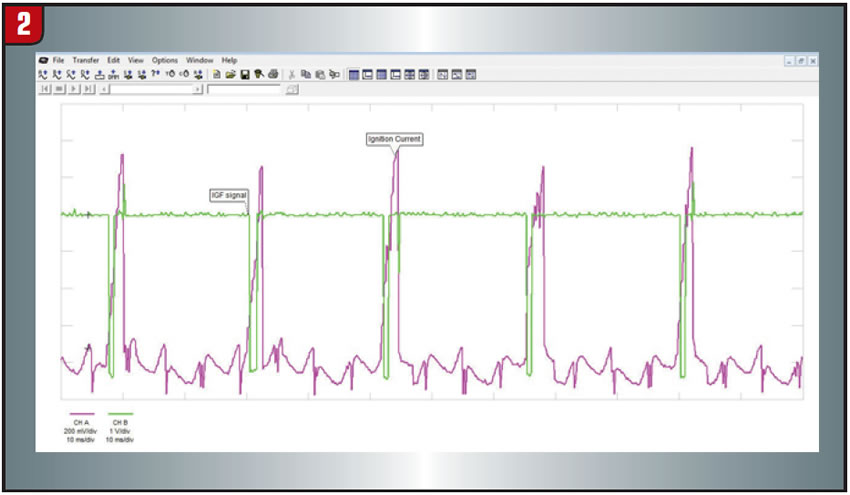

In Figure 3 you can see that the ramp on No. 4 cylinder (third in the order) rises sharply, indicating a shorted coil.

The second channel on the scope is hooked to the ignition-trigger signal.

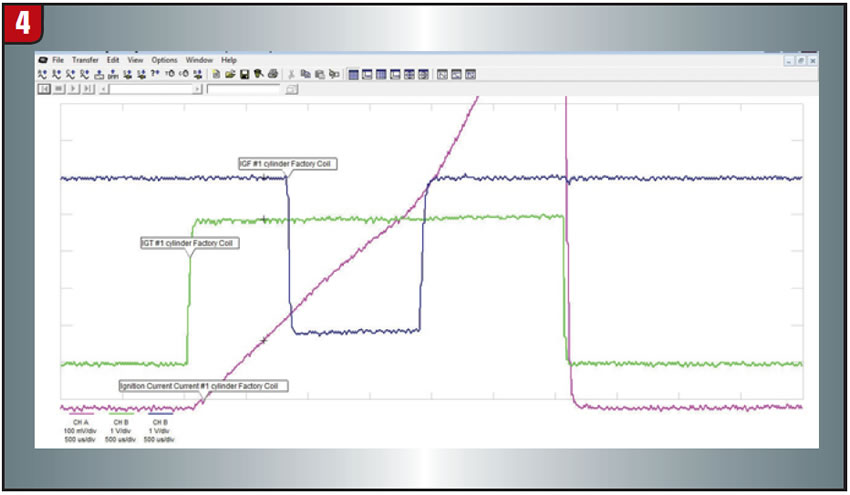

Even after I changed the coil to a good used factory coil the engine still made a terrible thrashing sound. I connected the scope to the coil’s ignition-charge current, the ignition-trigger circuit and the ignition-fire signal to get the waveform in Figure 4.

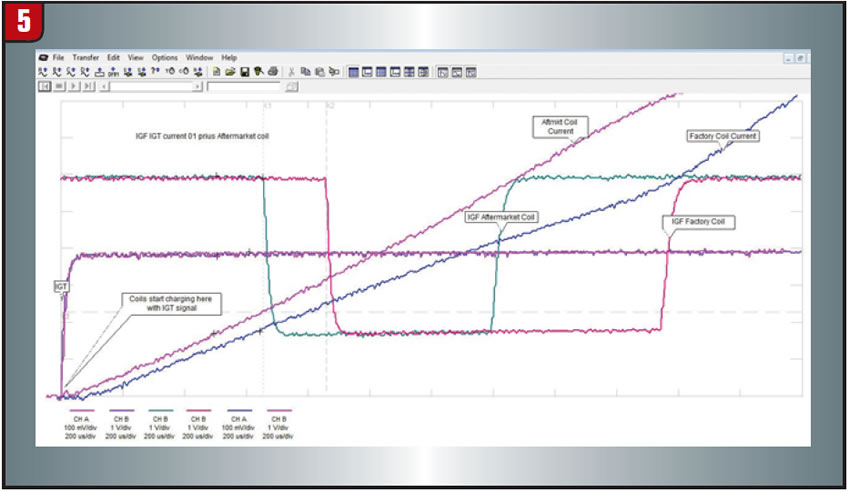

Next, I sped the scope to 200 microseconds per division and stacked one of the aftermarket coils with the factory coil to see whether the IGF signal looked the same.

The charge ramps in Figure 5 for both coils start at the same instant, but the IGF signals vary considerably. This difference essentially changes the ignition timing. I speculated that having the engine firing at different spark-timing-advance cycles might account for some pretty abrupt crankshaft vibrations. There are lots of posts all over the Internet in different Toyota blogs and chat rooms including my favorite (iATN) warning of using factory coils on Toyotas. This little test lets me see why it’s imperative to use a coil with the exact current ramp as the factory coil.

To see whether my theory would hold water, I changed the aftermarket coils for some dependable and used factory coils I pulled off of a good-running car. The engine started up and ran as smooth as the fur on a kitten’s belly. With this vehicle now in great running condition, I wish I had been a fly under the hood as I find myself having to sell it to someone and explaining the reason it has a title branded as “flood salvage.”

Jeff Bach is the owner of CRT Auto Electronics in Batavia, Ohio. You can reach him at johntjeff22@ gmail.com.

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.