Tech to Tech

- Subject: Engine cranks but won’t start

- Vehicle Application: 2001-03 Toyota Prius

- Essential Reading: Diagnostician

- Author: Jeff Bach

Hybrids require a different kind of troubleshooting

Crank no-start problems can be challenging when you’re dealing with a high-voltage (HV) battery. But specializing in hybrids has been one of the best decisions I’ve made. I have always enjoyed the challenge of working on “hard to find” drivability and electrical problems.

Not only is the hybrid a completely different electrical animal, there are so many inherent “traps” that one can get caught up in, that it can make for some interesting troubleshooting. There are plenty of opportunities to get involved with “fall through the crack” types of problems.

It is not at all uncommon to find yourself doing routine maintenance on, say, a Generation 1 Prius (2001-2003) only to end up with an engine that cranks but won’t start. I know this sounds ridiculous, but the scenario has happened often enough.

I know a technician who works at a Toyota dealer, and when I talked to him I mentioned that I had seen a Prius that came in from a lube shop with a dead HV battery as a result of cranking it down after some routine maintenance. He laughed and said they see them towed in on a regular basis over just such circumstances.

Something as simple as overfilling the crankcase with engine oil can cause a no-start situation. They hold only 3.9 quarts of oil. Four is too much.

When you’re changing the air filter, a small piece of debris can easily get lodged over the mass-air-flow (MAF) sensor and keep the engine from running.

These scenarios on a Gen I Prius will usually result in codes P3190, P3191 and P3101. These are the codes that let you know the engine cranked but didn’t start. You can get a ready light (meaning the vehicle will still drive) but you’re running on battery power alone. You will also have the red triangle light (triangle of death) on.

The P3191 sets in the engine-control computer without freeze-frame data. The engine-control module (ECM) is one of two “master controllers” on the Prius, the battery-control electronic control unit (ECU) being the other. Although the ECM is a master controller, it takes the back seat when it comes to the hybrid system.

The HV control computer is the one that has priority over the HV system and stores the freeze-frame data. It’s also the one that will need to be cleared when the “master warning light” comes on for an HV-system problem.

The P3190 and P3101 codes set in the HV ECU P3190 when the failure-detection condition meets the following criteria, conditions (a) to (e) at a fixed engine rpm for a fixed length of time:

- (a) Communication with HV ECU is normal.

- (b) Engine rpm is a fixed value or more.

- (c) Engine star mode is not active.

- (d) Target torque is a fixed value or more.

- (e) Ratio of estimated torque against target torque is less than 20%.

The following items are listed as trouble areas: air-induction system, throttle body, fuel pressure, engine, air-flow meter, out of fuel, water-temperature sensor, crankshaft-position sensor, camshaft-position sensor and ECM.

Once a problem like this occurs, it can easily compound and become an expensive nightmare for the technician and the shop. The problem here is that the engine cranks using the electric motor called MG1 and the HV battery. It spins more than 800 to 1,200 rpm for several seconds. It’s difficult to tell the difference between the engine cranking and the engine idling.

Once the codes are set you can’t even crank the engine again until the HV computer is cleared. Then, depending on the battery’s condition, you may get only a few cranks from it before it sets a low State of Charge condition code and disables the HV system altogether.

If the HV battery gets low, you’re dead in the water with no foreseeable way to recharge it. After that – the goose chase is on.

I have to admit the first time I had these codes, I made all the mistakes – including running down the HV battery – before realizing my dilemma. This forced me to come up with a better way to recharge the battery, rethink my diagnostic strategy, which would lead to a better understanding of this cranking system.

Fortunately, the car was one of mine that I purchased at an auction so I could experiment a bit. One of the first things that threw me was the fuel-pressure spec. The factory diagnostic information says:

Connect a fuel-pressure gauge to confirm the following:

- Fuel pressure is more than 43 psi (294 KPa) at idle (1,000 rpm).

- Fuel pressure does not decrease to 0 psi (0 KPa), five minutes after the engine is shut off.

- There is NO abnormal fuel-pressure-needle fluctuation during idling or driving.

Does the fuel pressure pass the above specifications?

The answer to this for me would be no. My fuel pressure was 43 psi exactly. I thought I was on to something. Remember the GM 4.3s – 55 psi start, anything below was a “no go”?

Since the fuel pump on these cars is part of the sealed fuel-tank assembly, I assumed it would be an expensive proposition. To my surprise my cost on the fuel pump and tank assembly was going to be only $163.98. Still, I wanted to be sure that was my problem before I ordered one, so I pulled in one of the other three Gen I Priuses I had on the lot and tested its fuel pressure.

Exactly 43 psi. The other two good-running cars measured the same also. Granted, these are all fairly high-mileage cars but they are running well with no high fuel-trim numbers pulling a hill. Turns out that this car was overfull on engine oil. Since then I’ve had numerous occasions to deal with these same codes.

Dirty throttle bodies are common because of the variable-valve-timing engine design. Dirty MAF sensors are also a common cause. I had one in here from another shop recently that had the HV battery down to where it wouldn’t crank, the crankcase was overfull, the engine was hydro-locked from a carbon treatment they had done and the MAF sensor was dirty. I had to charge the HV battery twice before I got the car to run under its own power.

Misdiagnosing one of these cars can be an expensive proposition. Once the HV battery runs down it sets a low-voltage code and won’t allow more cranking until there is sufficient charge in the HV battery.

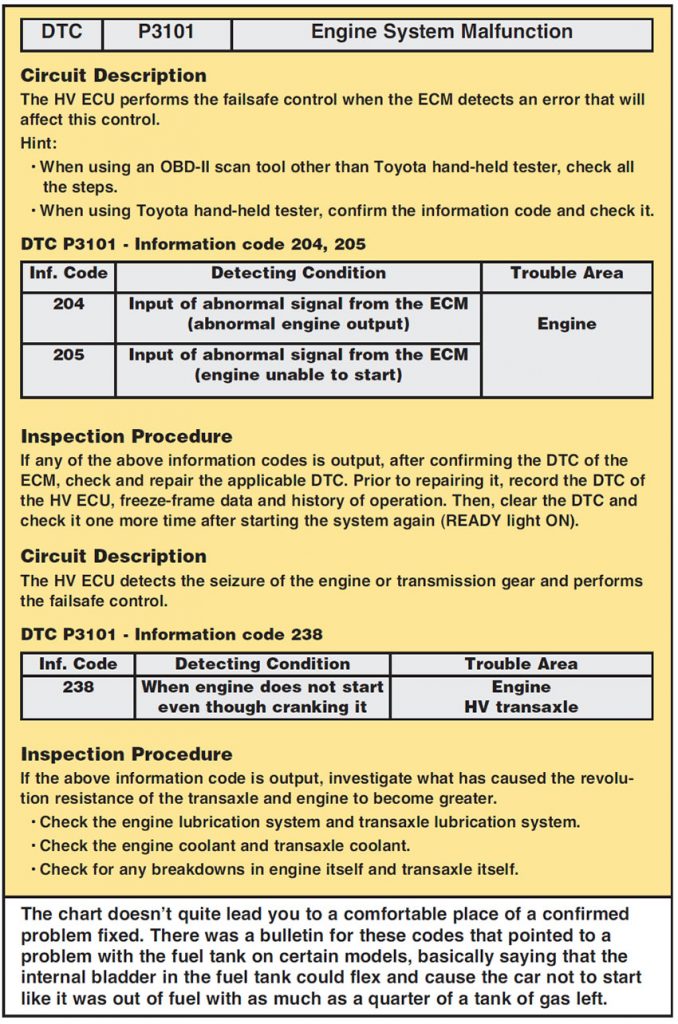

Now when I get one of these cars in as a “no-start,” I go straight to the freeze frame for the P3101 and try to gather as much info as I can before trying to crank the engine. Kind of like saving maybe that last crank until the car at least has a chance to start rather than wasting it trying to diagnose it.

The majority of the major issues that can arise when you’re dealing with these codes will be avoided by following a few simple steps. This is my boiled-down version of diagnosing this problem. Check the oil level and drain some out if questionable, clean the throttle plate if it’s dirty, clean the MAF-sensor element, check the codes and look at the freeze-frame data in the HV ECU for the P3101.

MG1 torque is a clue. The higher the torque value the less the engine is contributing. The last one I did showed about 4 Nm for MG1 torque while cranking the engine at 1,216 rpm. The power resource (HV battery) showed 16 amps. Exclusive info No. 3 should show 0; a 1 in this freeze-frame data parameter indicates that the computer has determined that the car is out of fuel.

You can watch the MG1 torque number go from positive to negative if the engine is actually running and producing power as it tries to replenish the HV battery state of charge (SOC). Happy hybriding!

Jeff Bach is the owner of CRT Auto Electronics, an ASA-member shop in Batavia, Ohio. For more information on this topic, contact Bach at 515-732-3965. His e-mail address is [email protected] and his website is www.currentprobe.com.

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.