TASC Force Tips

- Subject: Salvaging worn accumulator housings

- Unit: 4T60-E

- Author: Gregg Nader

Accumulator-piston wear is common and fixes are readily available, but the little pocket where the piston pin sits in the accumulator housing also wears, and this is a more-difficult problem to solve. This article describes a way to salvage accumulator housings using parts and tools you have lying around in your shop.

We have all seen worn accumulator pistons from the 1-2/2-3 accumulator in a GM 4T60-E. Figure 1 shows an example of excessive clearance in a piston-pin bore.

This clearance causes problems because line pressure leaks into neighboring lower-pressure accumulator circuits and effectively reduces clutch-apply pressure. Inconsistent shifts, slips, bumps and clutch failure are all tied to wear at the accumulator-piston-pin bores. The most-economical repair is to ream the pin bore and install the Sonnax 0.014-inch oversized replacement pins. Many times, however, the piston is worn so excessively that the oversized pins will not work. In these situations, the piston needs to be replaced.

The situation becomes more difficult when the accumulator housings have worn so excessively where the pin seats that even the 0.014-inch oversized pins flop around with no support. The following procedure allows you to salvage these accumulator housings, ensuring that the pins are securely held in place.

You will need the following items:

- 3/8-inch drill bit

- 2 accumulator pistons, with seals (to be used a drill-guide)

- 3/8-inch cup plug from a 604 overhaul kit (the one intended to be used when the park-link pivot shaft is removed).

Blunt the tip of the drill bit as shown in Figure 2 so it will stop at the bottom of the housing and not drill too deep. Drill through the two accumulator pistons with the 3/8-inch drill bit. It helps to use a new drill bit and pistons that are not excessively worn.

As shown in Figure 3, the drilled-out pistons will now work as an effective drill guide for drilling out the housing. The blunted drill bit will stop when it bottoms in the housing.

Installation is a snap. Place the cup plug over the new pin and drive it home.

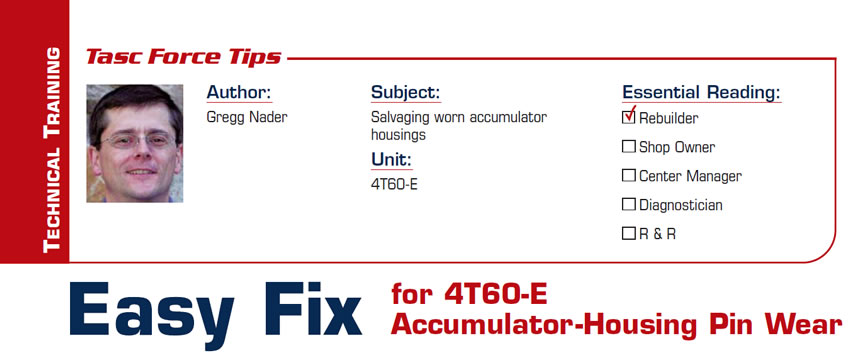

Figure 4 shows the drill in place after the housing has been drilled to accept the 604 cup plug.

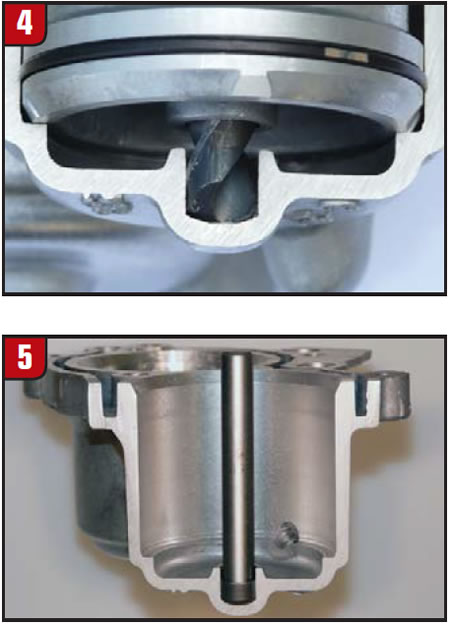

Figure 5 shows a cut-open section of a drilled housing with 604 cup plug installed and oversized pin held securely in place.

Gregg Nader is a Sonnax technical specialist and a member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.