Up To Standards

- Subject: Differential design and operation

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear Contributing Editor

Differential comes from different. In automotive terminology the differential is a component of a drive axle – either rear-, front-, or four- or all-wheel drive – that permits the axles to rotate at different speeds as the vehicle makes a turn. In a turn the drive axle toward the inside of the turn will have to rotate less than the axle on the outside of the turn because of the larger arc covered by the outside wheels.

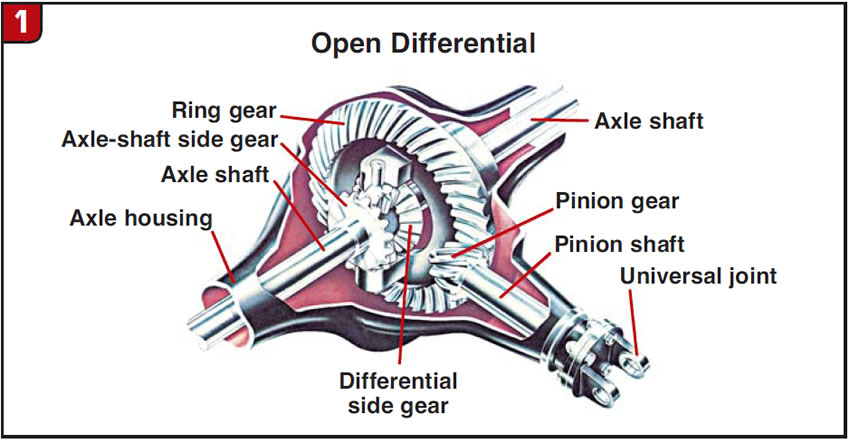

The differential is one of the most-misunderstood and misdiagnosed parts on a vehicle. A typical differential will consist of a case, usually of cast iron or steel, to which the ring gear is bolted. The ends of the case are machined to take a set of bearings that locate and hold the differential within the housing and at the same time allow for adjustments of the differential to permit proper pinion-gear to ring-gear depth and backlash (side-to-side adjustment) to ensure proper, quiet operation of the ring and pinion in mesh.

Within the differential case is a set of pinion gears supported by a steel cross shaft, and a set of side gears internally splined to locate the drive axles. This is known as an “open differential” and is capable of transmitting torque equally to the drive wheels.

In rear-wheel-drive (RWD) vehicles particularly, the torque transmitted to the wheels is a product of tire traction and engine torque multiplied by gear ratio. A single tire cannot receive more torque than either tire can transmit to the ground, so in icy, snow-covered or loose-ground conditions we get big-time wheel slip and loss of traction.

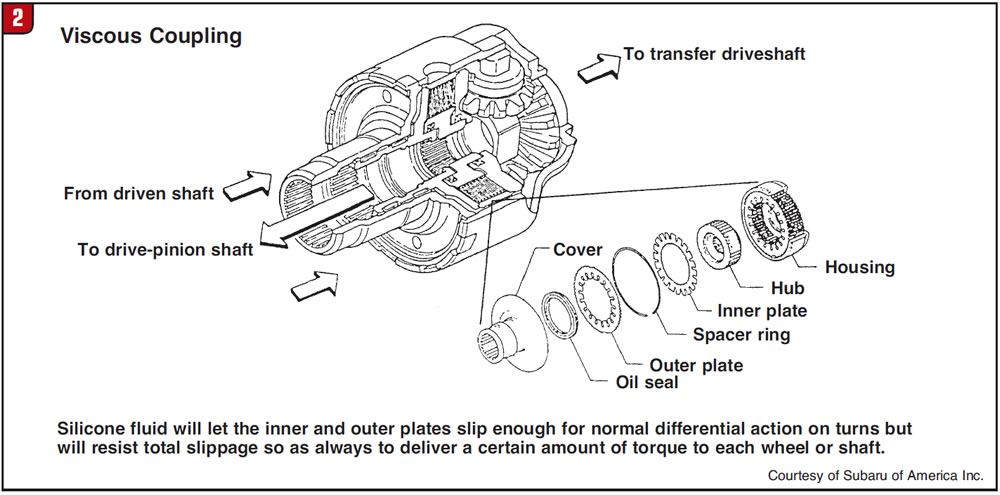

Front-wheel-drive vehicles operate on the same principle through the differential but because of the increased vehicle weight on the front wheels have better traction in the snow. As vehicle technology advanced, limited-slip differentials were designed to provide differential action in turns and transmit power to both drive wheels for enhanced traction. A limited-slip differential is a generic term for a whole family of differentials that provide enhanced traction through various mechanical designs. Positraction, Equa-lok, True Trak, Gov-Lock, Sure Grip, Detroit Locker etc. are brand names for units that use different methods of applying friction to the side gears to provide enhanced traction, safe operation and improved vehicle performance.

There are numerous classes of these designs that use preloaded clutches, self-applying clutches, a mechanical ratchet system, viscous couplings, worm gears and outboard clutch packs that can be applied independently to provide full lockup or differentiation of axle speeds through a corner. Because of advances in engineering and design some 4WD systems use a locking differential on both the front and rear drive axles and have a center differential in the transfer case or driveline to permit a certain torque split between the front and rear axles.

One of the most-overlooked issues that cause diagnostic nightmares for shops is failure to inspect the differential on FWD vehicles during transaxle teardown and rebuild. The differential is designed to work only in cornering. The problem lies with the customer whose vehicle has tires of different (measured) sizes or does not have equal air pressure equal in all four tires.

An example of this was a conversation I had many moons ago with a technician who had rebuilt a Mitsubishi KM-series automatic transaxle and had it back out of the car five times. He asked for help, and in the Q&A that went on he said the unit would come back in with fine black metallic dust in it and the valve body locked up. He had installed a rebuilt torque converter each time he pulled the unit and was convinced that the converter supplier was at fault.

As the unit was now apart on the bench, I asked him to take the side and pinion gears off the differential, which he admitted he had not done. I told him that in doing so he would find the washers behind the side and pinion gears to be worn out and smeared. He called me back and said this was the case and he would get new parts and rebuild the differential. At that point I told him to go out and measure the front tires on this car and tell me what he found. He came back and gave me the specs, and there was a 1-inch difference in circumference between the two front tires. The customer had installed a 15-inch wheel and tire in place of 14-inch because of lack of funds.

The point here is that this vehicle operated with two different axle speeds and the differential, instead of being inactive in a straight line, was working all the time, which rapidly ate the thrust washers behind the gears. Tire size and air pressure need to be equal on all the wheels, every time. It seems common for guys to clean the differential, particularly on FWD transaxles, without disassembling it. Once it burns you, you won’t ever do it again.

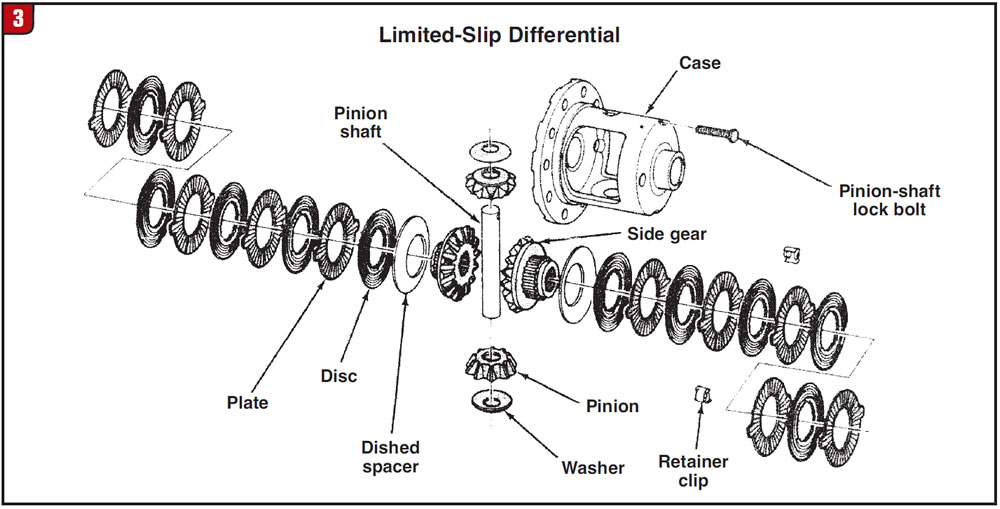

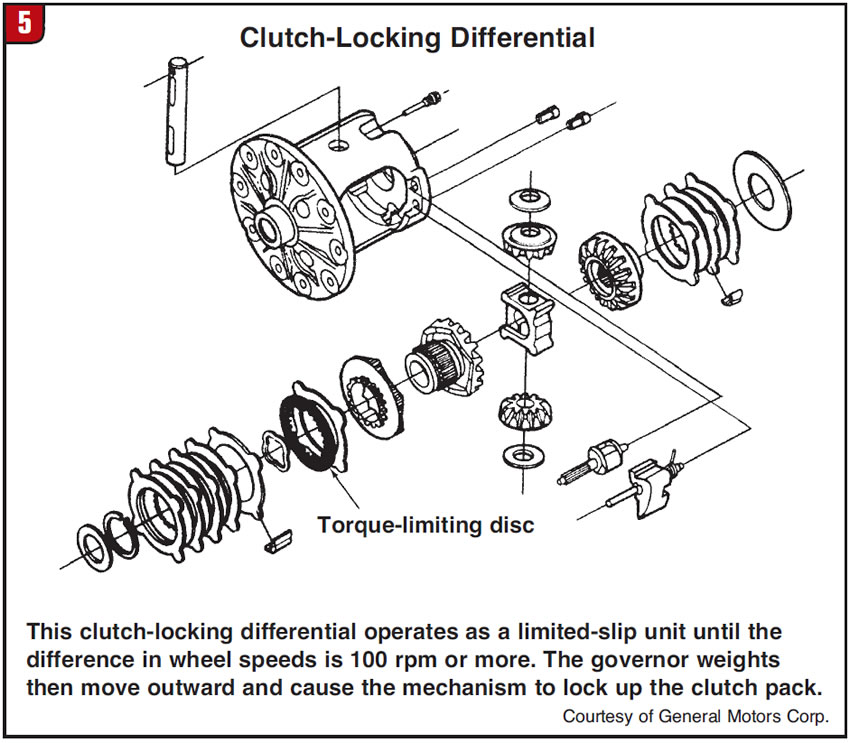

A limited-slip differential typically transfers most of the torque through the pinion shaft and gears like an open unit, with a certain amount of torque flowing through the clutch pack, cone clutches or worm gears to the opposite axle. Some limited-slip differentials work off clutch packs that are spring loaded with an S-shaped spring. Others achieve preload with a set of Bellville springs behind the clutch packs. Another manufacturer uses cone clutches that are preloaded to a certain friction level by coil springs similar to those of a hydraulic clutch. Then there is a Gov-Lock system that uses an internal governor in the differential case to apply the clutches when speeds differs by more than 100 rpm between the two wheels. Ford has a limited-slip unit that uses clutches and a set of pinion mate shafts and ramps to apply the clutches. One thing is clear: You need to know how the unit you are working on operates before you can diagnose and repair it properly.

Another paramount issue with clutch-driven differentials is fluid quality. All these units require a specific fluid additive to realize the full coefficient of friction available to the clutches, either cone or plate. Fluid quality is critical to proper operation. The oil in the lube never goes bad. It may look ugly but it is still functional. What has gone away is the additive package that gave the proper friction enhancers to the clutch packs so that they grab smoothly and hold under the heat and torque level generated. When the friction modifiers lose the additive package, you get a stick-slip action of the clutch packs, which leads to chatter in turns and some unpleasant noise and vibration. Limited-slip differentials use friction materials and they generate heat. This means you need to service them more often than an open differential, which should add to your bottom line if you sell service.

Gear-driven differentials have been around long enough, but we have been working with a new design that is actually an amazing improvement over past designs. Because of the expense of manufacturing a gear-driven differential as opposed to one using clutches, this unit was developed to replace the differential in late-model C5 and C6 Corvettes and is priced for performance use. However, I believe that as more of these units are sold, economies of scale will bring the price down to replace most of the current clutch-driven units.

Because of this really improved design, we will take a look at the future here. The IsoTorque is a unique, fully mechanical differential that provides a high torque bias without limiting differentiation as most mechanical limited-slips do. Being a geared differential with no electronics, it reacts instantly to changes in available traction between the two axles. Electronic units must sense wheel spin or some input from the driver before reacting. This means that the IsoTorque unit does its job seamlessly with no reaction to the driver, maintaining traction without any of the on/off behavior that electronic systems exhibit.

The IsoTorque accomplishes this through a series of gears linking the two axle shafts to the differential carrier. The side gears, splined to the axles, have a high-helix-angle tooth design relative to their axis of rotation. The balance gears are cluster gears, with helix teeth in the center and spur teeth at each end. The balance gears are placed in a cross-axis orientation to the side gears and have shallow-angle teeth relative to their axis of rotation, while the spur teeth link each pair of balance gears. Each balance gear has a pin through its center that links it to the differential carrier housing while permitting it to rotate. The other unique feature of the IsoTorque is the wear surface created in the gear mesh, which is larger than previous designs, creating a more-durable unit with greater load capacity.

In operation the power path starts at the pinion, travels to the differential through the ring gear, to the balance gears and finally to the side gears, which drive the output shafts (axles). Because of the shallow helix angle of the balance gears and their cross-axis orientation to the side gears, the balance gears prevent undesired rotational force in the side gears’ axis of rotation as a result of engine torque. This results in the differential rotating as a single unit, providing equal rotational speed to both axles regardless of available traction on either axle shaft.

Differentiation occurs when conditions such as cornering or uneven ground dictate that the two axles rotate at different speeds. The terrain places force on the axle shafts to create a speed delta between the output shafts and the differential carrier; this flow of input torque is called the differentiation path. This causes the side gears to apply force on the balance gears. The high helix angle of the side gear in relation to its rotational orientation places most of the force into the axis of rotation of the balance gears, allowing the side gears to easily rotate the balance gears, providing differentiation with minimal effort. A look at the enclosed diagram will go a long way to help you understand the engineering theory you just read.

Understand the various differentials and how they work. They all need service, and these are items you can sell a customer to improve his vehicle performance and his safety.