Up to Standards

Author: Mike Weinberg, Contributing Editor

Subject Matter: Dual-clutch transmissions

Issue: Electronics

Last in a series on dual-clutch transmissions

Electronics in Dual-Clutch Units

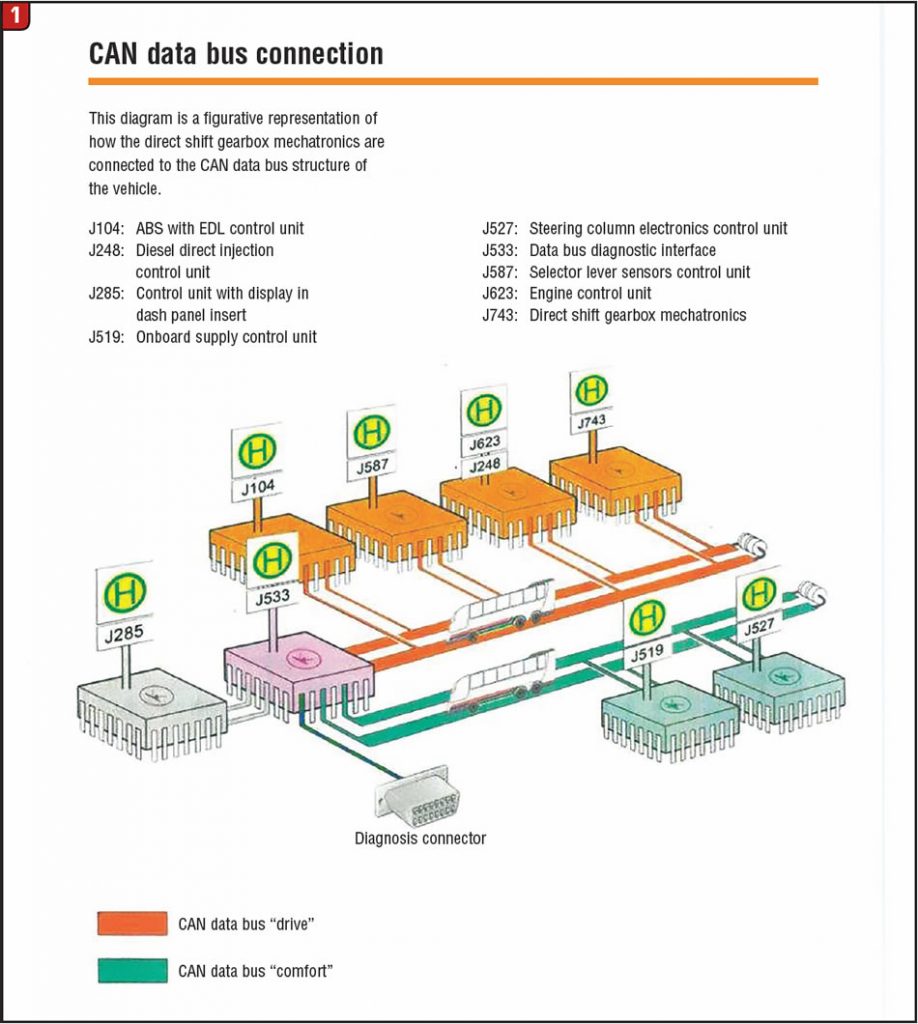

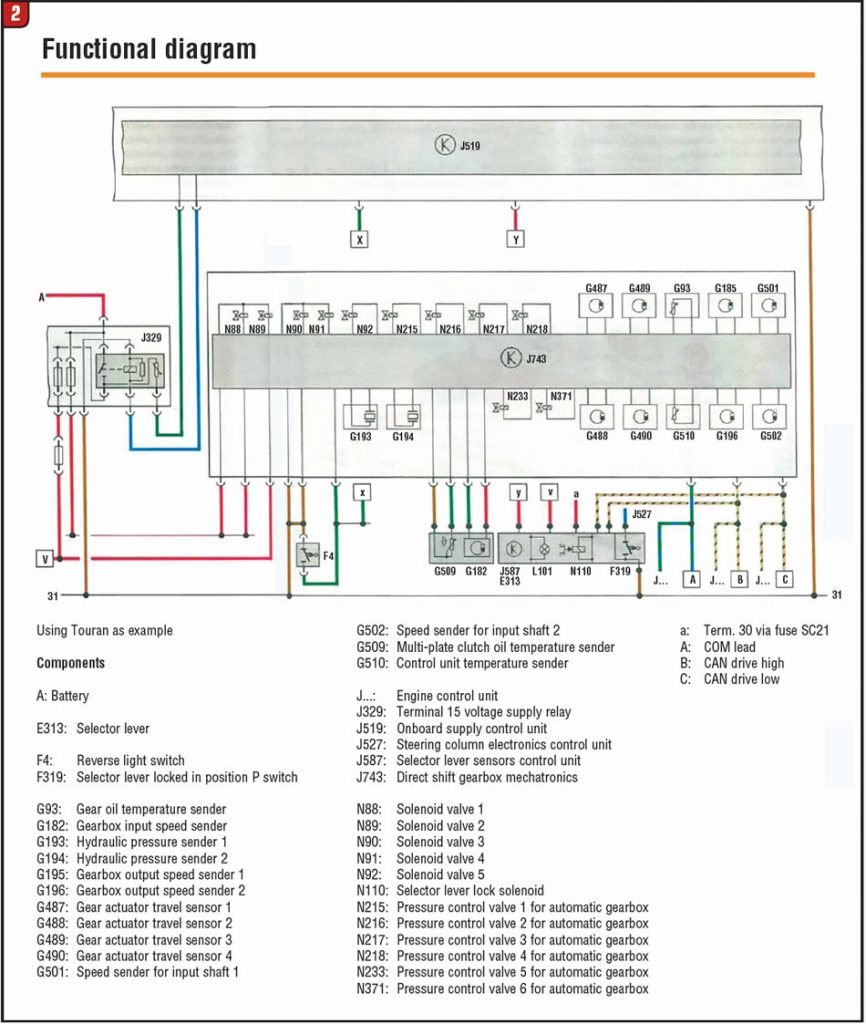

This article is the final segment of our exploration of the dual-clutch transmission, or direct shift gear box (VW and Audi) or DualTronic in BorgWarner’s brand. We have included several schematics from a VW Touran model, as VW has the largest amount of these transmissions in use. VW using its VAS 5051 diagnostic system provides for, as they say, “guided fault finding,” which means that a test schedule is available for the unit and provides testing for sensors, actuators and the mechatronic (computerized) valve body.

This permits observation of the components in actual operation. Using the schematic, the sensors, which are G-series numbers; the actuators, which are N series numbers; and the Mechatronic fault sensor circuit, which is J743, may all be tested and diagnosed. It is also possible to determine oil level of the gear box in the Guided Functions mode.

If you have been following this series on the dual-clutch gear box, you know that change is on the way in the industry. While you may not yet have seen any of these in your service bay, they will arrive. Change is the only thing constant in our industry. We have besides DCTs, CVT transmissions, and a huge group of automatic transmissions that range from four to 10 speeds that we will have to become familiar with in order to survive.

Ford and GM have collaborated on a new 10-speed automatic trans that has a ratio spread between first and 10th gear of 7.384. The goal here is economies of scale in manufacturing and development for the two automakers, and the constant need for better fuel efficiency, increased demands for emissions controls, and driver comfort. Closer ratios spread across more gears creates an ability for these computer controlled units to maximize efficiency and keep the vehicle at the optimum gearing for the rpm level and road conditions.

Newer designs will utilize torque converters that lock up quickly and remain locked up through most of the drive cycle to create better fuel economy. Shift cycles that are controlled by hydroelectric valve bodies and the elimination of accumulators reduce the lag in shift timing, again for more efficiency. Clutch packs will be supplied with springs between the clutch plates for instant release of the components to minimize parasitic power losses due to clutch drag.

There is a huge premium on getting the computer control software programs absolutely spot-on and tailored for the driver’s expectation of comfort as well as handling all the various conditions associated with driving. Nothing is being overlooked to reduce every bit of friction in rotating components such as the replacement of all flat thrust washers with needle roller bearings. In the new GM/Ford 10-speed automatic, there are two pumps. One of these is a variable displacement pump that is not driven off the mainshaft, but gear-driven to make a shorter overall length transmission while reducing horsepower losses from the pump drive. The second pump is an integrated electrically driven pump which give the transmission the capacity to run in start/stop configuration for further fuel savings.

Transmission fluid is being constantly refined to improve efficiency even further. Typical ATF has a viscosity of 7.5 centistokes. Newer six-speed automatics are designed for a fluid with a thinner viscosity of 6.0 centistokes, and the new 10-speed fluid, which is Mercon ULV, has an even thinner viscosity of 4.5 Centistokes. All of this happens to reduce the parasitic losses from the pump drives, and to reduce drag and friction on the clutch elements.

Learning & obstacles

To be a professional auto technician, you must also be a professional student, as the new designs and manufacturing processes demand that your knowledge must never stop increasing. What separates the winners from the losers here is all self- determined. If you like what you do and can’t wait to learn more, you will go far. There are, however, two distinct issues that constrain your forward motion, and they are good sources of real information, and the ability to obtain the correct parts in a timely manner at reasonable prices. It is getting harder and harder to get the correct information. At the same time we have “captive parts.”

Both are a creation of the manufacturer to keep the work on these vehicles going back to the dealer service department. For instance, most transfer cases for domestic models are designed and manufactured by BorgWarner and Magna Powertrain. When they are contracted by the OEM, the contract will state that the OEM will pay the tooling costs (which are huge) and that anything made on that tooling cannot be sold to anyone else. The service parts for these units are now captive to the dealer. Solving these two problems will insure our success with the new models we will have to deal with to stay in business.