Up To Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Dual-clutch transmissions

- Issue: Hydraulic and fluid controls

Fourth in a series on dual-clutch transmissions

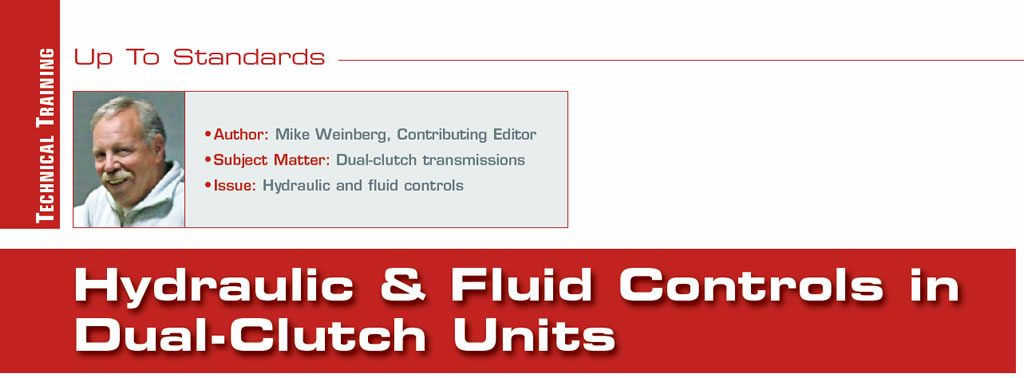

To recap, we have looked at how the dual-clutch transmission functions, essentially two gear boxes in one with the input shafts driven by hydraulically applied clutch packs that drive three concentric shafts that are one inside the other. The innermost shaft drives a gerotor-type of fluid pump that provides pressurized fluid to actuate the dual clutches, lubricate and cool the components, and shift the transmission into the selected gear. The next two shafts are driven by the two clutch packs with one shaft shifting the even-number gears and one shifting the odd-numbered gears.

There are dry-clutch models of the dual-clutch transmission, but they are only designed for lower-torque vehicles with the main difference being that dry-clutch models do not have a need for hydraulic cooling of the wet-clutch packs. As in an automatic torque-converter transmission, most of the heat generated in transferring engine torque occurs in the torque converter, and in the dual-clutch units the lock up of the clutch packs occurs through friction and generates heat. The friction of the gear train in mesh does not create appreciable amounts of heat. The fluid distribution is controlled through an electro-hydraulic valve body and a number of hall-effect sensors, which BorgWarner calls the Dual Tronic control module. VW, which is at present the largest user of these units, calls the valve-body electrical-control unit Direct Shift gear box Mechatronics.

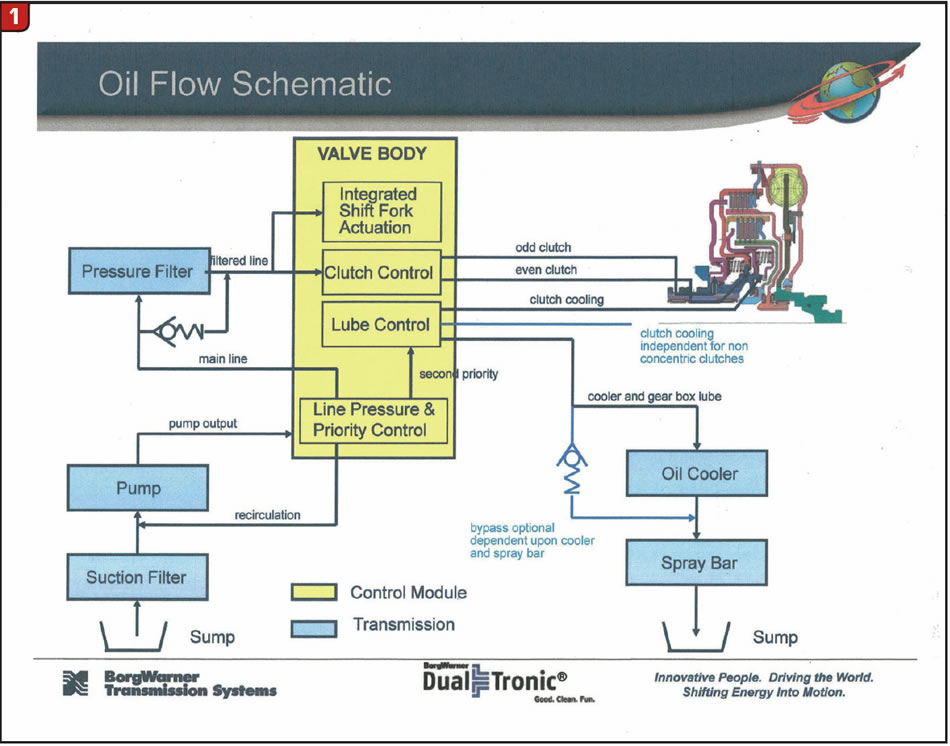

There are two schematics included here. One is a very general look at the components put out by BorgWarner (Figure 1); the other is a view of the actual components of one of the VW transmissions, a front-wheel-drive model (Figure 2).

The hydraulic section of the valve body (Mechatronics) is very similar to late-model automatic valve bodies, a combination of valves to distribute fluid and for pressure regulation, coolant flow; and electric sensors to regulate pressure, temperature, shift fork position, shaft speeds, and output from electronic sensors and solenoids to control and regulate fluid flow. In this article we will look at hydraulics and the various sensors involved, and we will devote the next article to understanding the electronic circuits and functions. There is no way to discuss the hydraulics without mentioning the electric sensors and controls involved.

VW Mechatronic overview

- G509 is the sensor for the wet-clutch temperature and is located next to the clutch packs. The same sensor assembly contains G182 which senses input shafts speed from the clutch pack.

- Output-speed sensors for the 1 and 2 output shafts are labeled G195 and G196. The input shafts speed sensors are G501 for shaft 1 and G502 for shaft 2.

- There are two senders for hydraulic pressure, G193 and G194.

- The units have two oil temperature senders, G93 for gear oil temperature and G510 for control unit temperature. The mechatronics unit is housed inside the gear box and is immersed in the operating fluid.

- There are four shift forks in the unit, each equipped with a travel-position sensor to inform the control unit of its position. G487 for 1st and 3rd gears, G488 for 2nd and 4th gears, G489 for 6th and reverse gears, and G490 for 5th and neutral gears.

- Mounted on the steering wheel are two Tiptronic paddles (switches), which are E438 and E 439, permitting the driver to shift the unit manually without taking a hand off the steering wheel.

- The shift selector lever sensors control unit J587 communicate with the Mechatronics and the vehicle Can Bus system to indicate shifter position, which permits the unit to function as an automatic gear box. The shift selector is also equipped with a locking solenoid N110.

- The mechatronic unit contains 3 pressure control valves, N215, 216, and 217. There are eight solenoids N88, N89, N90, N91, N92, N218, N233, N371.

The VW schematic will show you the graphic placement of these components and hopefully you will realize that there is nothing here that you do not already work with. This is the future, and if you are not learning to understand and live with it, you will be on the side of the road while the parade of paying jobs goes by.