Up To Standards

- Author: Mike Weinberg

- Subject Matter: Dual clutch transmissions

- Issue: Electro-hydraulic controls

Third in a series on dual-clutch transmissions

If you have been following the previous chapters of this series of articles, you are starting to understand the function of dual-clutch transmissions. We have used illustrations from the VW Direct Shift Gear Box (DSG) as VW has about 2 million of these units on the road at present.

Borg Warner, an old and familiar name in the transmission industry, calls their design Dualtonic. Borg Warner has decades of experience in design and production of automatic transmissions and components, manual transmissions and transfer cases. The company has invested heavily in the development of the dual-clutch components. Borg Warner produces the wet clutch components, various internal parts, and the control systems for many of the units being produced.

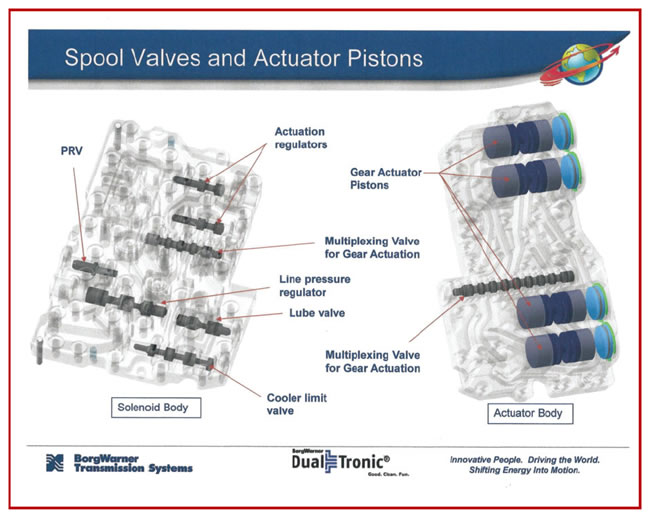

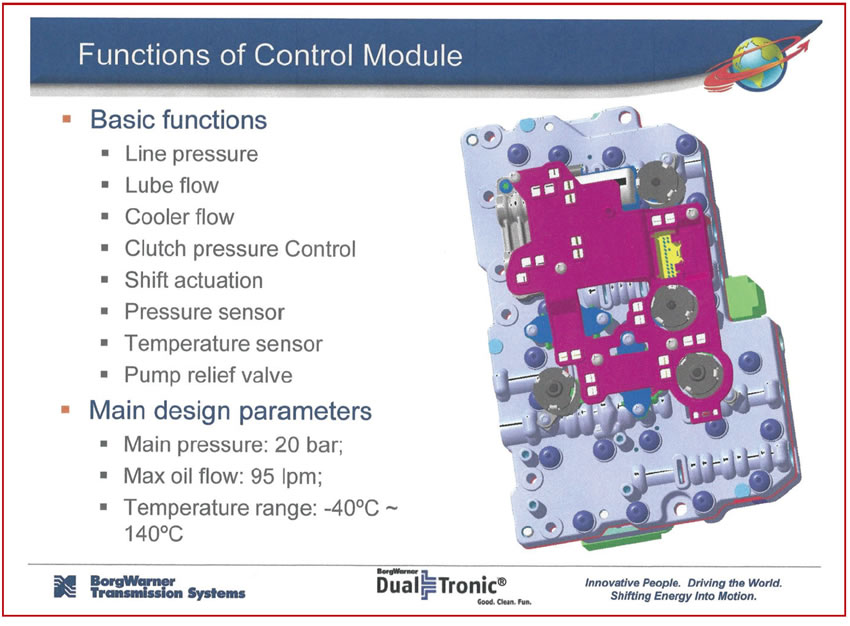

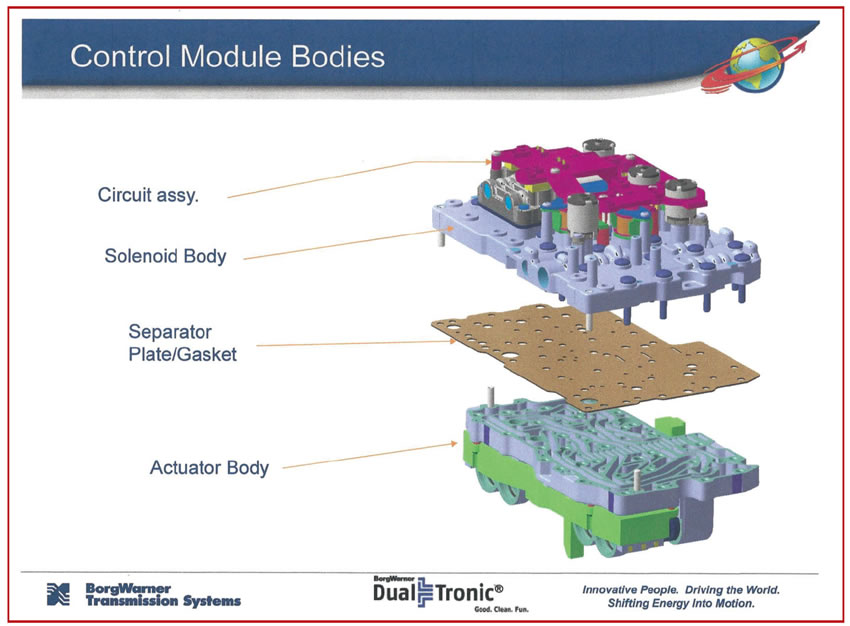

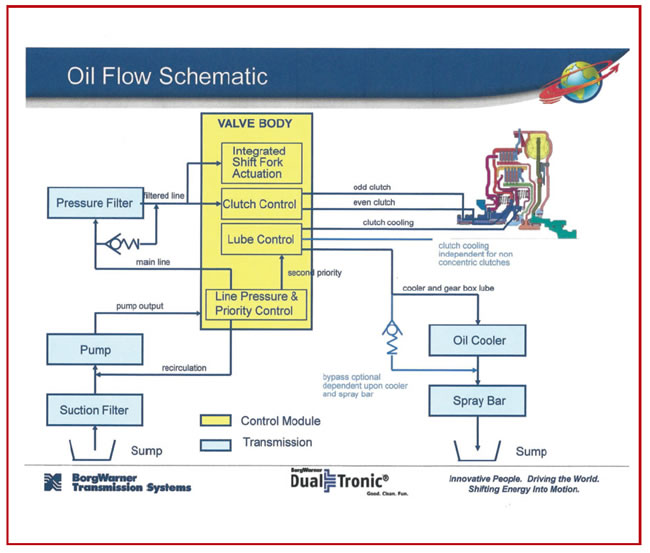

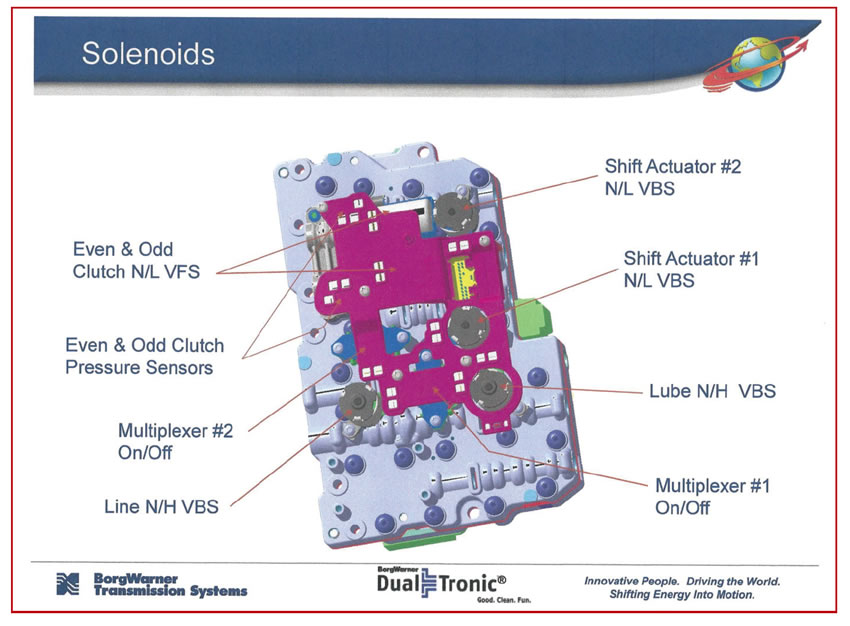

We will look at the control systems of these units in this chapter to understand the brilliant new engineering designs that will find their way into our shops in the future. The transmission control module is mounted internally in the gear box. VW calls this system “the Mechatronics Module,” as its brand name ID. What we really have is a very sophisticated computer-controlled multi-stage valve body, which has an electronic control unit and an electro-hydraulic unit that regulates all shift function, control sensors, pressure regulation of the internal oil pump, hydraulic application of the dual clutch components and lubrication functions. The unit is located internally to the trans and is surrounded by oil. The Mechatronics module contains 12 sensors, with two other sensors outside of the Mechatronics system. This makes for a very compact system with centralized wiring into a large connector, reducing multiple electric connectors and wiring to remove failures due to external sources, and provides for reduced weight in the assembly.

The other efficient aspects of this design are the direct connection from the Mechatronics Module shift actuator valves to the shift forks that select each gear. This eliminates shift rails, rods, and other linkage that are found in normal manual transmissions internally and externally. This direct design reduces any play normally found in old-style rails and linkages and makes shifts happen in a little as milliseconds. Incorporated into the shift forks are permanent magnets that operate as hall effect sensors to inform the computer of the fork position on the selected gears.

Included here are a number of diagrams that are much easier to understand than a lot of description on my part. The illustration/diagrams are courtesy of Borg Warner and do not reflect the actual Mechatronics layout, but serve to explain the theory of operations far better than print media can.