Tech to Tech

- Subject: Intermittent no-start condition

- Vehicle Application: 1997 Saturn SC1

- Essential Reading: Diagnostician

- Author: Brian Manley

Tips for troubleshooting intermittent failures and no-starts

What is your knee-jerk reaction when a vehicle rolls into your bay with the following concern: intermittent no-start? Personally, I usually like to know the make and model of the vehicle so I can tag it with a pattern-case failure (and I will revisit this point a little later), but this can often lead me to dangerous and time-wasting conclusions.

Case at hand: This ’97 Saturn SC1 sitting in my stall with an intermittent no-start concern started up each time I cranked it, and it ran well on a subsequent test drive. It took many attempts throughout the day before I duplicated the customer concern, but the no-start was brief and it didn’t recur enough to dive into a diagnosis. Finally, when the engine would not fire up, I caught it in a state of no spark, and then I began narrowing my diagnosis from there. When I also found that I had no fuel pressure, I looked for common causes, and that led me to discover that I had no “key-on, engine-off” power to several critical fuses in the underhood junction block, including those for the powertrain control module (PCM) and the fuel injectors!

At this point, the first thing that popped into my head was the possible demise of a main power relay – you know, like the ones for Chryslers or Hondas that deprive their respective PCMs of power and render the engines “dead.” However, scrutinizing the schematic revealed no such relay. Power supply for the PCM and fuel injectors flowed as follows: battery to 30-amp ignition fuse in the underhood junction block, then through the ignition switch, and then to a 10-amp fuse in the instrument-panel fuse box, then back to the underhood junction block, where a single, 10-amp fused circuit fed the PCM, fuel injectors, electronic ignition, exhaust-gas recirculation and backup lamps! “Wow,” I thought. “Why do some manufacturers use a relay to handle this much current flow, and some don’t?”

When my Saturn stayed “dead” long enough to allow me to funnel my diagnosis to conclusion, I found the culprit: a defective ignition switch. Specifically, what had failed were those overworked contacts that feed the circuits described above!

In a recent Tech to Tech article, I explained the perils of fretting corrosion: The tendency for some male/female connections to develop excessive resistance over time. My focus this time is the burning, pitting and metal transfer that occur each time a set of high-current contacts is switched on and off, and specifically how excessive resistance in these contacts creates unique troubleshooting opportunities for you and me.

Ignition-switch failures

How many of you have experienced this failure on a vehicle? What form did it take? I have replaced two of these in as many months, which is a lot for me, and both had separate symptoms. The previously mentioned vehicle was dead in the water, and the other car simply lost its HVAC and audio systems.

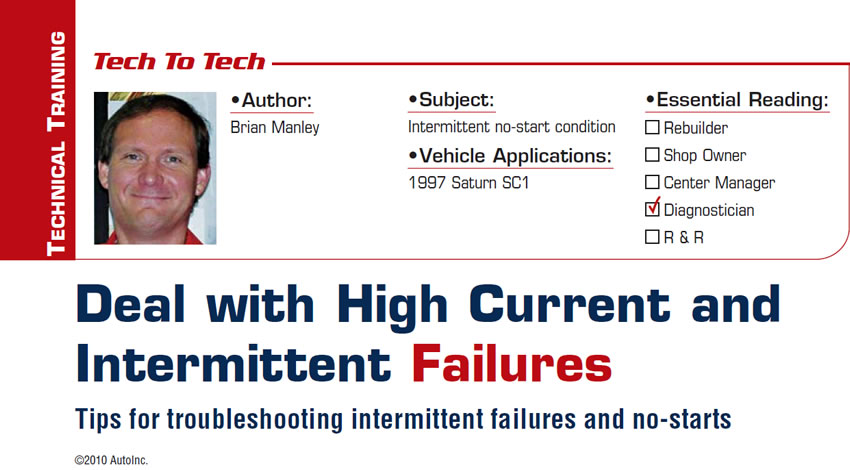

After disassembling the ignition switch outlined in the failure above, I discovered a set of worn, pitted, darkened contact points (Figure 1). It was then, while staring at these contacts through a magnifying glass, that I wondered: “Should we replace such high-current-carrying contact areas as a matter of scheduled maintenance? Should we be preemptive with regard to replacement of these important electrical parts that can leave our customers stranded? The ignition switch and the vehicle had 170,000 miles on them.

I remember a time when we replaced timing belts all by themselves at 90,000 miles; now many of us up-sell the “kit” that includes all the idler pulleys. A kit for a recent 1999 Subaru with a 2.5L engine came with timing belt, water pump with gasket, timing-belt-tensioner assembly, right timing-belt idler (smooth), left lower timing-belt idler (smooth), cogged timing-belt idler, two accessory drive belts, front crankshaft seal, four camshaft seal kits, thermostat, thermostat gasket and miscellaneous needed hardware.

Why are we more comprehensive regarding timing-belt replacement? We’re looking out for our customer’s safety and peace of mind. Along this line of thinking, does replacing an ignition switch on a high-mileage car before it fails seem ridiculous? What about relays?

Main-relay failures

Other high-current devices that can leave our customers stranded are relays, especially main relays that control the PCM, ignition and fuel delivery. A “Tech Night” discussion on iATN (the International Automotive Technicians’ Network) revealed how some technicians deal with this subject. Several technicians talked about the symptoms of failure for the Ford electronic-engine-control (EEC) relays and the main relays on Hondas, saying that when the vehicle acts a certain way they replace the relay (based on pattern-case-failure diagnostics). As you and I know, this often works and saves a lot of diagnostic time but sometimes backfires. The discussion soon revealed a great point that I had not thought of: replacing relays as a matter of maintenance based on vehicle mileage.

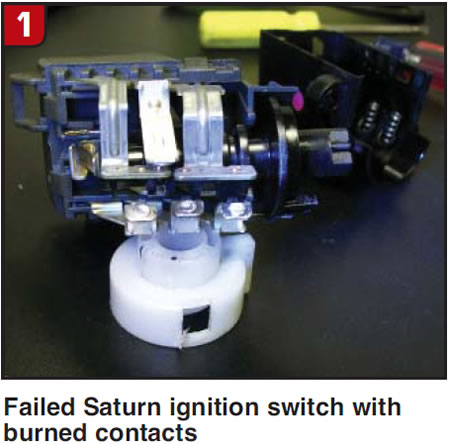

After contemplating this for a while, I see the logic. Relays are relatively inexpensive compared with a tow, and some vehicles have only one or two “critical” relays. The exception to this rule may be in the form of Ford’s constant-control module (Figure 2) of the 1990s engines that contained the fuel-pump, PCM, air-conditioning and cooling-fan relays. During a recent repair, I discovered that these modules can run as much as $200.

Starter-motor relays/solenoids

A friend of mine has been replacing the contacts in Toyota gear-reduction starters for years instead of replacing the entire starter motor, which can run upward of $400. These NipponDenso starters, which fit many Mitsubishi, Toyota, Chrysler and Honda vehicles, are repaired by some technicians by installing a new solenoid plunger and contacts. These are the highest-current-carrying contacts on these vehicles, and I’m often surprised they last as long as they do. Is this the right thing to do? I offer customers an informed choice, and some will opt for an entirely rebuilt or new starter-motor assembly, which is my choice as well.

Accessory contacts

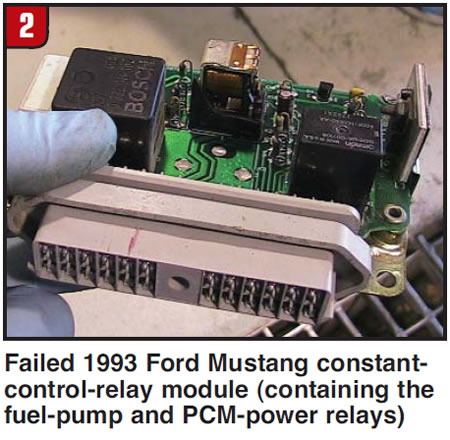

I think we have all been faced with a driver’s power window that won’t go up or down. If the cause is a “bad” switch (Figure 3), then the contacts can often be cleaned to make it work again. I will do this for customers who need their window working today but their part won’t be in until next week.

What have I learned?

Following my last ignition-switch replacement, on the Saturn, I am not comfortable recommending the replacement of this part until it fails. However, I am now more apt to use a digital volt/ohmmeter or a lab scope to test the integrity of this power source to critical components, especially if I am in the middle of an “intermittent-failure” diagnosis.

After learning about technicians who replace main relays as preventive maintenance, I have to say that I will recommend relay replacement on some vehicles to some of my customers who have the financial means and the foresight to support such a decision.

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. You can reach him at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.