TASC Force Tips

- Author: Gregg Nader

Do you recall that feeling you get when you first figure out that the transmission on your bench has been worked on before? The signs could be obvious, like a painted case, but other times it’s not until you start tearing it down that you see clues that someone has been there before you. For me it is always a bit of a disappointment, because I know I have to watch carefully for changes that someone else made that could affect the transmission when I’m finished with it.

One of the modifications I have had questions about is the practice of drilling line-to-lube. Line-to-lube is a modification that adds an orifice between the line and converter-charge/lube circuits to ensure that some oil will be fed to those circuits even if the pressure-regulator valve moves out of its normal regulating position. Some units are manufactured with oil circuits like this. For others, adding a line-to-lube orifice is a well-accepted rebuild procedure that, if done correctly, contributes to unit durability. But it has some drawbacks.

One of the drawbacks is that it can cause converter drain-back and delayed engagements after the vehicle sits. Additionally, if the added hole is the wrong size, it can overcharge the converter, leading to other problems such as ballooning and front-seal leaks. The reality is that drilling the correct-sized orifice at an odd angle in a valve-body casting is a very tedious process. All too often we find castings that were drilled out with too large a drill bit, or even if a smaller bit was used the resulting hole is larger than intended. Rather than having an open line-to-lube hole in the casting, many builders prefer installing one of the pressure-regulator valves available in the aftermarket that supplies additional converter-charge/lube oil.

A simple method of plugging these holes is with a very small solid aluminum rivet (see Figure 1). A lifetime supply of 500 pieces is available from McMaster-Carr for about $7 as item number 97481A065 (you can order at 609-223-4200). This is a 1/16-inch-diameter, 3/8-inch-long aluminum flathead solid rivet and is available from other sources as well.

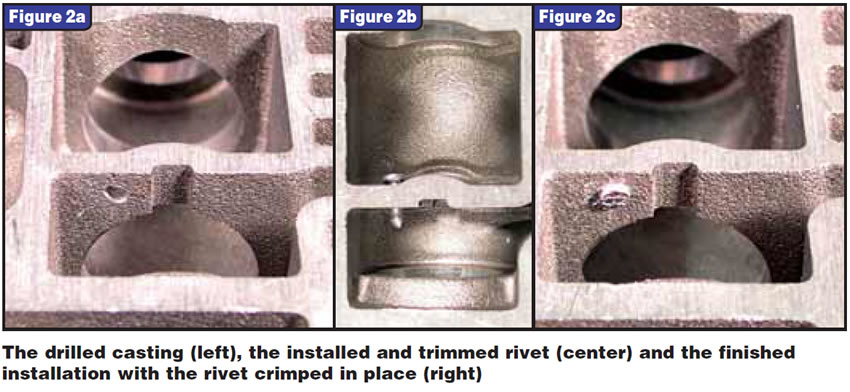

Figure 2 shows the rivet being installed. If the hole you are plugging is smaller than 1/16 inch, re-drill to 1/16 inch and install the plug. This rivet is long enough to plug holes that are 1/4 inch long. For shorter holes, just insert the rivet and trim off the excess with a pair of side cutters. Leave a small amount of the rivet on one side and then crimp the rivet with needle nose pliers to mushroom the one end and securely tighten the rivet into the hole.

That’s it. With the hole plugged and the line-to-lube hole effectively erased, you now can use this casting as if it had never been modified and build the unit up using the parts and procedures you prefer.

Gregg Nader is a Sonnax Technical Specialist and a member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. ©2007 Sonnax Industries Inc.