Tech to Tech

- Subject: Diagnosis of no-start condition

- Vehicle Application: 1991 Chrysler New Yorker

- Essential Reading: Diagnostician

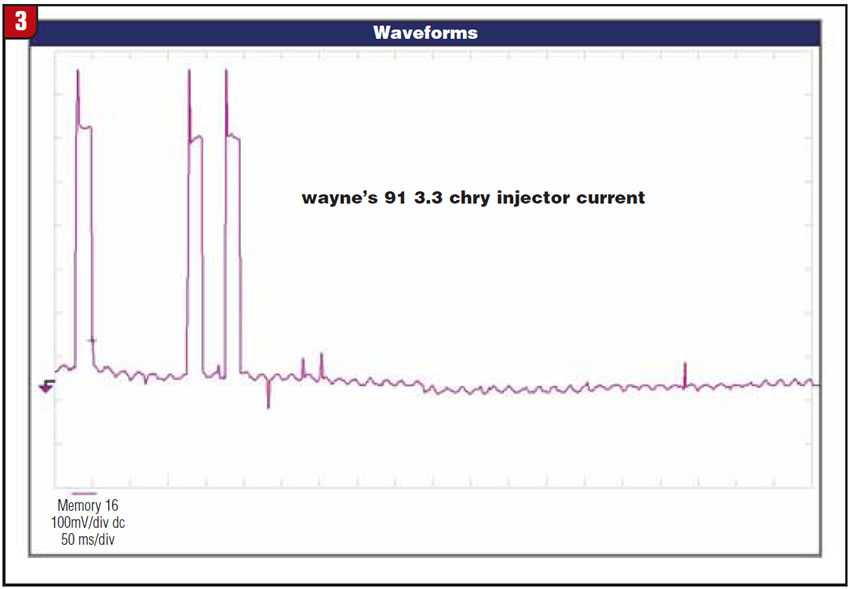

- Author: Jeff Bach

It’s easier to be a ‘rocket scientist’ than to diagnose a car these days

“Well, I guess it’s time to figure out if she’s worth me throwin’ any more money into the old gal,” Wayne said as he tossed me the keys to his ’91 Chrysler New Yorker. “She just up and died this morning when I went to start her. See if you can work your magic on her and let me know what it’s gonna cost to bring her back.”

“OK,” I tell him as he walks out the door. Wayne is way up on the list of my favorite customers – maybe even at the top. He’s one of these guys who takes whatever life throws at him and finds the bright side to it. Never a cross word and always a smile. He seldom has questions about a repair and usually doesn’t ask for an estimate. He just says, “You’re the doctor – do whatever it takes.”

This time, however, he was trying to decide on whether to retire this car and move on to another. He has two vehicles already running well, and this one is a spare. Clean as a pin for a ’91 and still well under 100,000 on the clock. Ideally, I’d like to have been able to tell him what the cost would be to get the car running without spending a lot of diagnostic time trying to find out why it quit. I mean, it’s a 3.3 Chrysler; how hard can it be?

When the wrecker sets the car down, one of my guys goes out and cranks it for a preliminary “shoot-from-the-hip” diagnosis and says, “It sounds like maybe a fuel pump.”

He grabs a can of carb cleaner and spritzes it into the air-intake boot. The car starts and dies. “I’ll bet it’s the fuel pump,” he says reassuringly.

I see the test and the results, and I’m thinking it does seem like a waste of time doing all of that testing and diagnostic data that I like to collect when this one seems so cut and dry. Three “key-ons” ago, I got no codes, and I could definitely hear it fire up and die. I began to wonder if I should think about some of my other problem jobs and just let my guy stick a fuel pump in this car and be done with it.

Then I remember the sign on my front door that reads, “Test, don’t guess.” I put it there as a reminder to myself years ago, and I see it every morning when I come in. Sometimes it seems like a curse. It keeps me from jumping to the obvious quick conclusions that make a lot of guys in this business money when they guess right.

Still – I love the testing part of my job. I love seeing those waveforms and watching things take place like they are supposed to or catching them when they don’t. This time I listened to that inner voice that said: “Show the guy on paper how you knew he needed a fuel pump. He is your favorite customer, after all, and you do charge for diagnosis; give him the dog-and-pony show he came for.

“You’re right,” I say to the voice, and I get my scope and current probe.

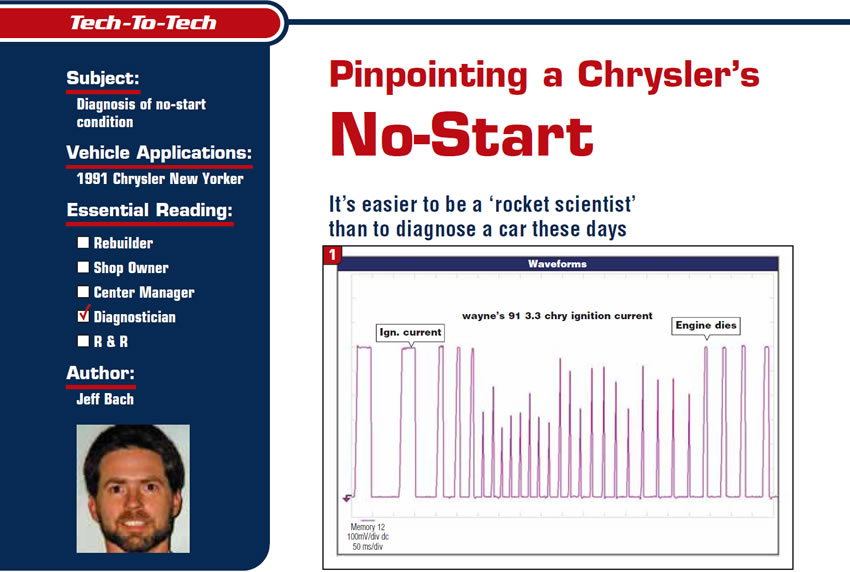

Meanwhile, the car has been pushed in and is on the rack set to lift it. “Hold up a minute,” I say to my guy as I fumble around under the hood looking for a good spot to grab a fuel-pump waveform. “I wonder if this thing uses cam/crank-sensor alignment logic to determine ignition and/or fuel,” I think to myself. I reach in and hit the key again for another listen and the engine starts and dies again – only this time, without a spritz. A few more of these, and I decide to connect my scope to the easily accessible ignition coils feed circuit just to see whether the ignition current was dropping out. Figure 1 was my first result.

Just as I never suspected – the ignition current continues on just fine until the engine stops. By now I’m getting some ribbing. “We’re going to put a fuel pump in it as soon as he gets done with all his testing,” I hear my guy say to the new guy (part-time trainee) who just arrived after school.

“Well, if we already know what’s wrong, why is he still testing?” I hear the new guy ask.

I guess that when I look so engrossed, at times I appear invisible.

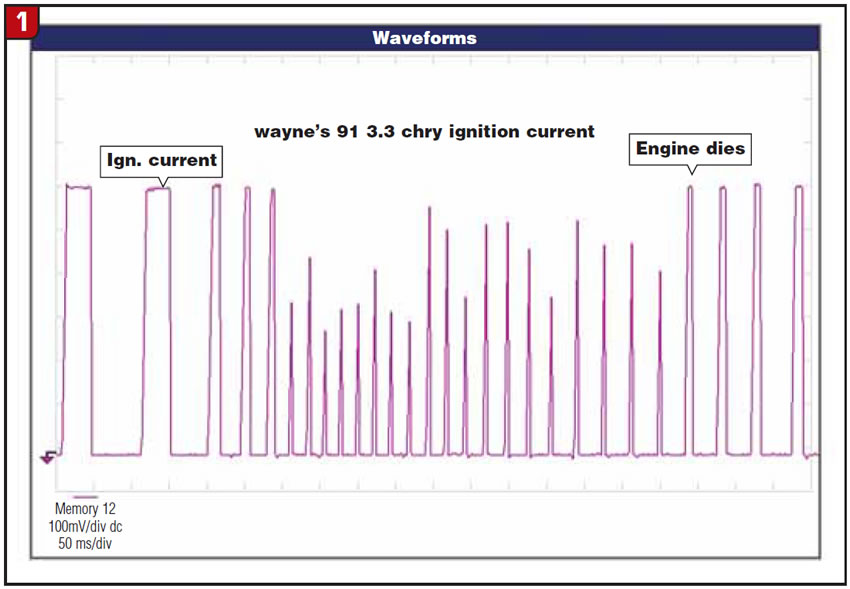

I decide to move on to the injector current since I have easy access to the front bank. I collected the image in Figure 2 that shows one pulse and no more during the start-and-stall cycle captured this time.

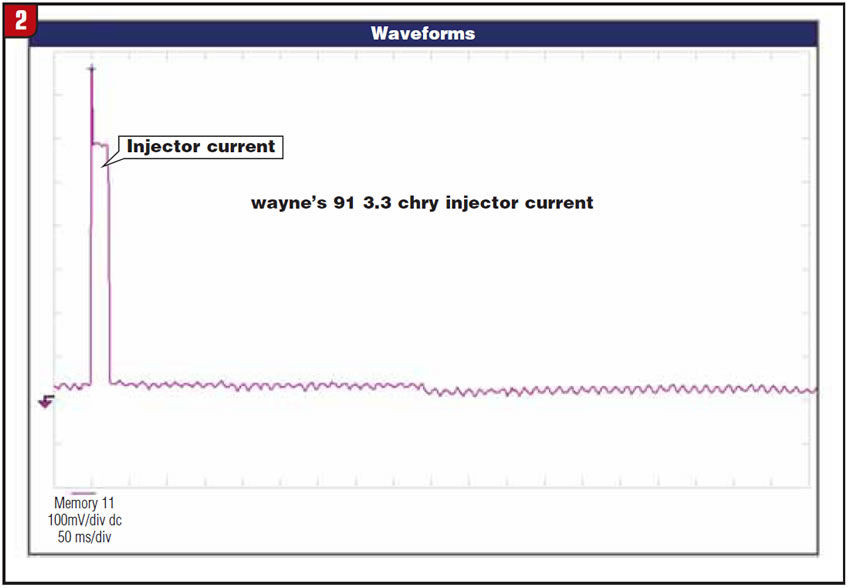

Suspecting now that I may be on to something that might make a valuable lesson for the impressionable new kid, I call both of them over to show them what dramatic image I’ve just captured. Suspecting that cam/crank correlation issue I’ve been running across in some of Chrysler’s other products, I disconnect the cam sensor and crank the thing again. Figure 3 was what I got. Pretty much the same.

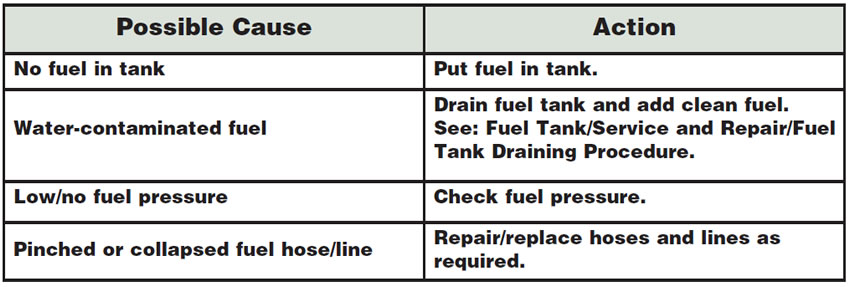

While searching for a cam-position/crankshaft-position (CMP/CKP) correlation waveform in my “data source,” I ran across a symptom diagnostic chart that I thought might be helpful just because the symptom chart defined my condition so well. Here’s what it said. Definition: “Engine cranks OK, but does not start. May fire a few times.” Then it listed these actions (see chart). That’s all the possibilities and actions listed.

I found a CMP/CKP correlation waveform listed in the iATN library and compared it with mine. I concluded that the timing components weren’t misaligned and moved on to other possibilities. I collected some more signals from the vehicle and decided that the powertrain control module (PCM) had all the data it needed to continue triggering the injectors, but it was not doing that, so it was likely stuck in the “vehicle theft alarm (VTA) mode” that I read about on the iATN library. There were multiple instances of vehicles that were exhibiting the same symptoms as mine that required PCM replacement because of theft-mode lockup when the vehicles (like mine) had no theft-deterrent option.

I searched through my data source for the bulletin mentioned by the dealer techs but couldn’t find any reference to it. I concluded that this was one of those “mystery” vehicles that decided the time was right for a nervous breakdown. I contacted the customer, Wayne, and gave him the news, which he received rather well. I had the guys reluctantly push the car outside to skeptically await the arrival of the good but used single-board engine-controller (SBEC) module I found online at a salvage yard.

Once it arrived, I plugged it in and the car started like it was just turned off.

I showed my customer the diagrams and explained my reasoning to him and how I decided the computer was at fault. He said, “Geez, you guys have to be part rocket scientists to figure these cars out anymore.”

I smiled. “Rocket scientists have it easy,” I said. “I mean, how many different models of rockets are there, really?”

Jeff Bach is the owner of CRT Auto Electronics, an ASA-member shop in Batavia, Ohio. For more information on this topic, contact Bach at 515-732-3965. His e-mail address is [email protected].

The copyrighted article featured above is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.