R&R Tech

- Author: Troy Hopp

- Subject Matter: Wiring problems

- Issue: Harness makeover

As I think back about all the bizarre wiring issues I have encountered over the years, there is one that sticks out in my mind.

We had a 1998 Ford Contour come into the shop with a transmission wiring harness that had been completely chewed up by mice. I mean every wire in this harness had exposed copper running the length of the harness for at least two feet in one spot, and I can recall at least 10 wires shorting out against each other, causing multiple codes and drivability issues. I asked myself why this mouse (or these mice) would choose to feast on this poor, unsuspecting wiring harness?

After a quick Google search, I found that some car companies were using biodegradable soybased wire insulation. They are no longer using plastic nonbiodegradable wire insulation, and that has to be more environmentally friendly, right? One would certainly assume!

It is more than likely more economical as well. Unfortunately it is also more inviting and tastier to all the rodents of the world. What could be better than a nice cozy warm engine bay to build your nest in, and have a free meal to boot!

Well, enough talk about those mischievous mice. Let us get to the issue at hand. Recently a young lady had a 2005 Ford Taurus towed into our shop.

The complaint was that it suddenly quit moving. As most of you in the transmission business probably already know, the torque converters in these cars have been known to break, causing the vehicle to just suddenly stop moving. Naturally after verifying that it did not move and the odometer showing 187,419 miles, I wanted to automatically blame it on the internals of the transmission, given their long history of failure. However, I also know the foolishness of just assuming this, so some quick testing still needed to be done before condemning the transmission.

Over the years I have found the easiest and most efficient way to verify a bad transmission on a Taurus that does not move is to simply disconnect the solenoid connector, since it is right there at the top of the transmission, wide open for all to see and very easily accessible. If the vehicle still will not move, then it is probably safe to assume the problem is in the transmission, or possibly a broken half shaft.

Well, guess what? My initial assumption was, well, dead wrong.

After disconnecting the solenoid connector, the transmission actually went into gear and would move, indicating a possible external wiring issue. Of course this would be the case, or I would not be writing about it, right? Now it was time to grab the scanner. A quick readout of the history codes revealed a whole plethora of problems.

The codes almost too numerous to list were as follows:

- P0300 – Random misfire detected

- P0316 – Engine misfire detected on startup

- P0430 – Bank 2 catalyst efficiency below limit

- P0442 – Evap system leak detected

- P0713 – Transmission fluid temperature sensor high input

- P0740 – Torque converter clutch fault

- P0743 – Torque converter clutch electrical fault

- P0750 – Shift solenoid A fault

- P0753 – Shift solenoid A electrical

- P0760 – Shift solenoid C fault

- P0763 – Shift solenoid C electrical

- P1744 – Torque converter clutch system performance.

Whenever I see this many random codes all in one place, I start bracing myself for a blockbusterselling horror story of wiring mayhem! The search was on. A thorough visual inspection of the underhood wiring revealed a hidden mess of chafed, corroded and blackened wiring hiding beneath what used to be 1-inch round plastic conduit (Figure 1).

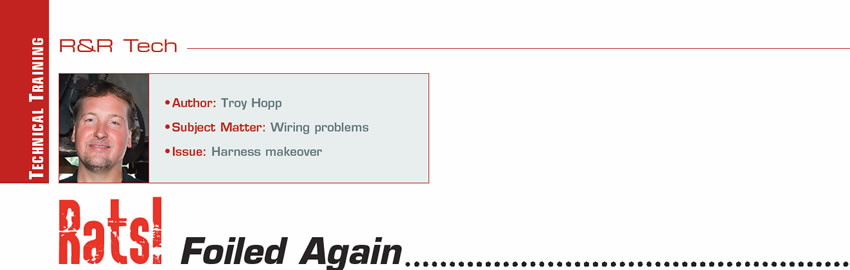

Located between the front edge of the engine and the right side of the firewall near the right strut tower (Figure 2), the wiring harness was totally grounded out and melted against an aluminum air conditioning tube that had to be physically and forcibly pried apart.

After observing the nightmare of chafed wiring, I knew it would take the rest of the day to repair, and I turned my eyes to see the grooves that the wiring had actually implanted into the aluminum A/C tubing like a bunch of corn rows (Figure 3). I am surprised the Freon did not all leak out.

After giving the wiring harness a makeover, the transmission lives to see another day. The nice young lady was extremely pleased that she did not have to buy a transmission and that she only had to purchase a wire repair plus a transmission fluid and filter change. I guess the point I am trying to

make with this story is to remember that not all failures that appear to be the same are created equal, and that the same old familiar road does not always lead down a straight path. Sometimes curves appear out of nowhere, forcing you to dig deeper with your diagnosis.

I actually kind of enjoy the challenge, though. Challenges keep us thinking, and after all, life would certainly be boring if you had to go to work and do the same repetitive things day after day.

Oh and by the way, the rodent eating soy-based wire insulation problem I mentioned at the beginning of this article can now be easily avoided or at least deterred. Companies now offer a form of electrical tape treated with capsaicin, which is the same stuff found in hot peppers that turns

chili into 3-alarm-fire chili, thus deterring the mice and other rodents from having a free meal.

Honda sells 20-meter rolls of it for around $36. The more you know …