TASC Force Tips

- Subject: Identifying transmission models

- Units: 41TES (41TE VLP), 42RLE-VLP

- Essential Reading: Rebuilder, Diagnostician

- Author: Robert Moreau

One would think the easiest part about working on transmissions would be identifying the model you are working on. Nowadays, unfortunately, it’s not always that easy. I was helping via e-mail a technician on a transmission forum who reported having issues reaming a late-model Chrysler FWD valve body. Both he and I were thinking 41TE (A604), but that turned out to be incorrect. What he was working on was actually a 41TES, also known as 41TE VLP.

VLP stands for “variable line pressure.” This late-model 41TES incorporates a line-pressure solenoid to control line pressure, plus a line-pressure transducer that provides feedback to the control module. The main reason for these two added components is to enable the computer to monitor and reduce line pressure during idle engagements to a more-appropriate level on the basis of the calculated load, the end result being improved fuel economy. The RWD configuration of the 41TE (known as the 42RLE) also was modified in the same manner; Chrysler refers to it as a 42RLE-VLP.

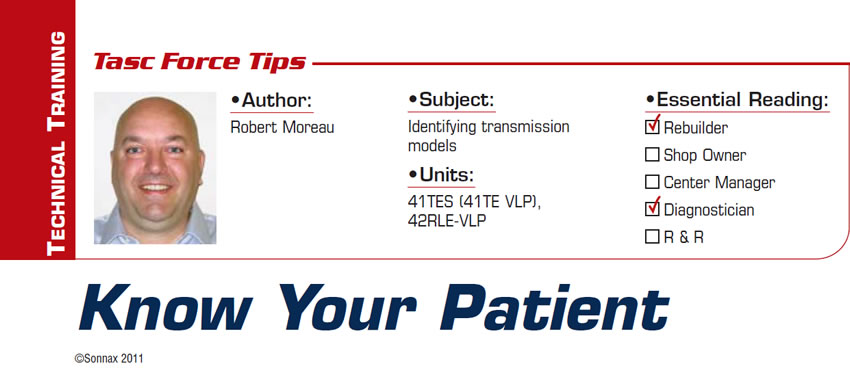

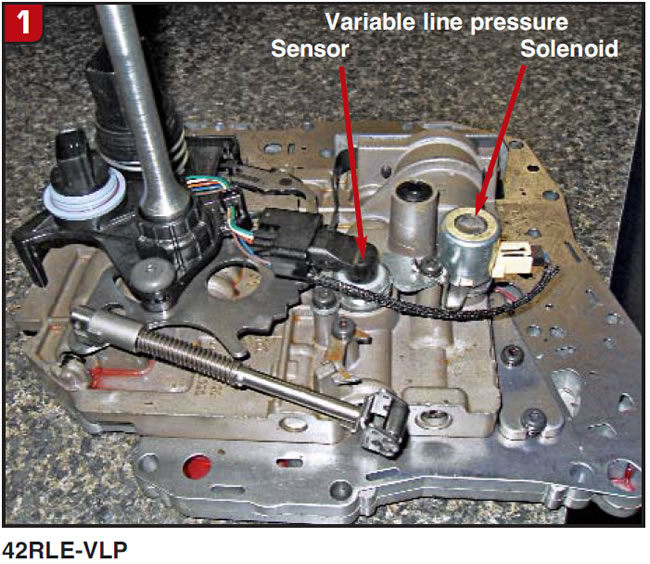

So, just how hard is it to know whether you are working on one of these VLP models? Thankfully, it turns out that once you know what to look for, it is a breeze. Figure 1 shows a 42RLE-VLP valve body, and Figure 2 shows a 41TES valve body.

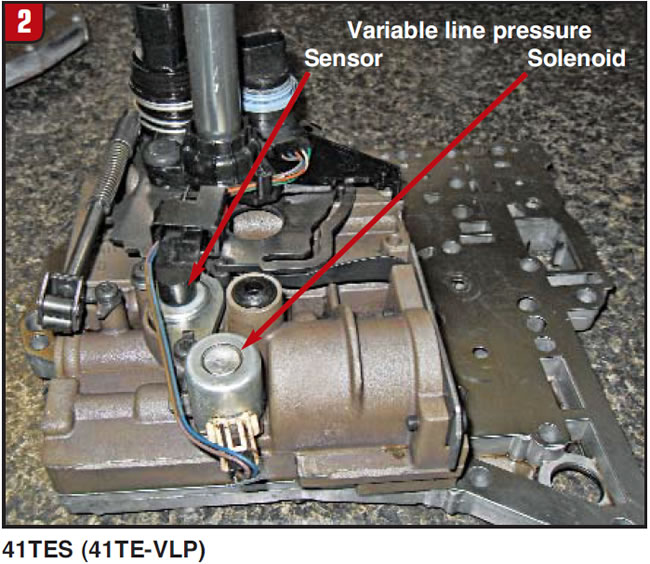

As you can see, you can’t really miss those solenoid and sensor components. Notice that, aside from the mounting bracket, the line-pressure solenoid is almost identical to the governor-pressure solenoid on the RE series. A second pass-through connector is mounted on top of the range sensor with a wiring harness to connect both the transducer and the solenoid (figures 3 and 4).

The transaxle case in these VLP models has an extra hole next to the one for the range sensor’s pass-through connector. The valve-body and transfer-plate castings are slightly different to physically accommodate the two new components and provide hydraulic passages for them. The pressure-regulator valve goes to a one-piece anodized valve, and the separator plate has two extra holes. None of these parts are interchangeable between VLP and non-VLP units.

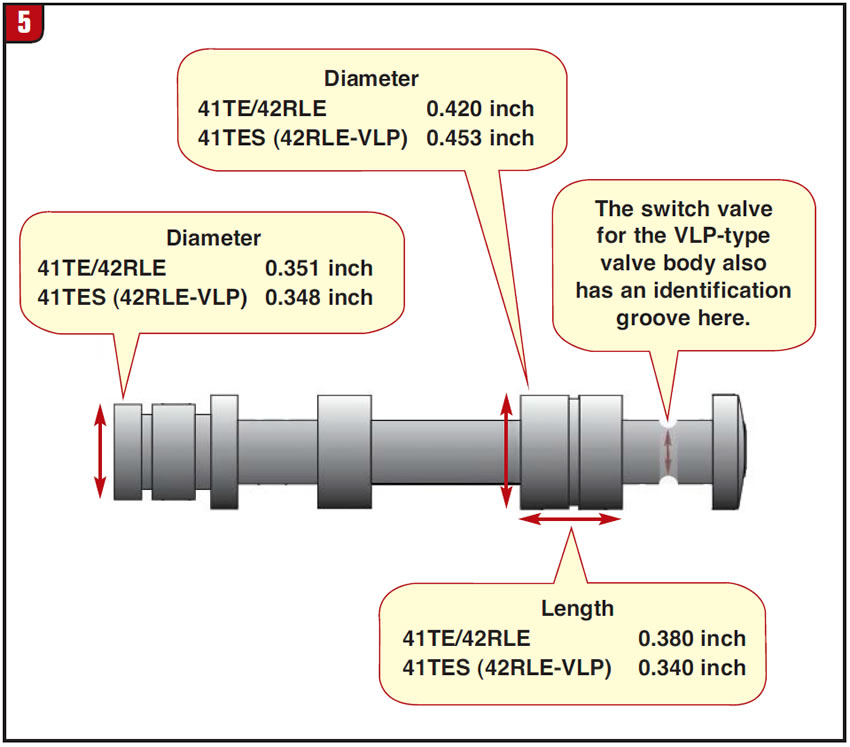

Now for the not-so-obvious differences: Remember the technician with his reaming problem at the solenoid-switch-valve bore? Well, it turns out that at the same time Chrysler went to variable line pressure, it also made three pretty subtle changes to the solenoid-switch-valve dimensions. As you can see in Figure 5:

- The small-spool diameter is 0.003 inch smaller

- The large spool is 0.033 inch larger

- The biggest land is 0.040 inch narrower

- The valve has an added identification groove.

Now, that’s easy to miss if you ask me; a major TRAP!

For this reason, unfortunately, neither the Sonnax oversized switch valve 92835-21 nor the end-plug kits 92835-02K/92835-18K will fit this VLP-style valve body. At first glance, it looks as if end-plug kit 92835-02K would work as the diameter is identical, but it is not recommended. The reason is that the most-inboard Sonnax end plug is actually 0.040 inch wider than the OE design for extra support to help prevent bore wear. When the valve is positioned against the end plug, the combination of the wider land on the Sonnax part and the changes to the OE spool does not allow proper valve-spool positioning relative to port openings.

More important, even Sonnax oversized switch-valve-plug kit 92835-18K cannot be used in a VLP unit. The biggest danger here is reaming. The Sonnax reamer 92835-TL for this switch-valve-plug kit has a pilot on the end that relies on the switch-valve bore to support and guide the reamer. If this reamer is used in a VLP unit, the larger bore does not guide the reamer properly and you will most likely ruin the valve body. You must use Sonnax switch-valve-plug kit 92835-22K and reamer 92835-TL22 on VLP units.

Keep in mind that the differences between these VLP and non-VLP Chrysler units are the ones we have been able to identify, but there may be others. At least now you can easily identify the newer design, and I hope it helps you make a little more sense of all the various nomenclature for those two transaxles.

Special thanks to Marc Saba from Automatic Kings in Riverside, Calif., for his research assistance and photography.

Robert Moreau is a Sonnax technical marketing-support coordinator and a member of the Sonnax TASC Force™ (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.

©2011 Sonnax