42RLE buzzing noise on initial engagement

The complaint A 2005 Jeep Wrangler equipped with the 42RLE transmission had a buzzing noise when the shift selector was moved to the drive position. The vehicle was actually brought in with a shift complaint, at which time the owner of the vehicle also said that the buzzing noise was present since he purchased the

Easy fixes to common transmission problems

Transmission makers are always throwing the repair industry curveballs. The challenges seem endless. Sometimes manufacturers will let us know of changes they are doing, while other times they let us figure it out as we go. I would like to go over a few examples we’ve encountered that may help you on a simpler installation

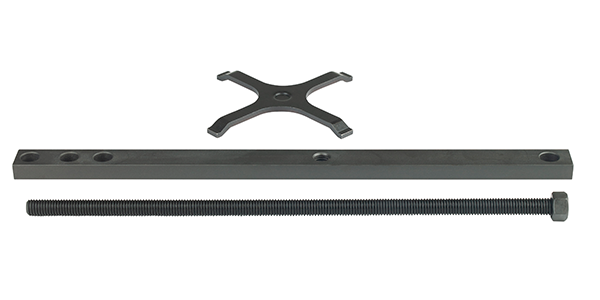

Return Spring Compressor for Dodge, Chrysler, Jeep Applications

OTC has recently released several tools for Dodge, Chrysler and Jeep applications, including a spring compressor used to compress the 2-4 piston return spring during removal or installation of the retaining ring in automatic transaxles. Applications include 1989 and later A-604, 41TE, 41AE, 42LE automatic transaxle, and can also be used on 42RLE transmissions.

Unresolved

Mike Greer breaks down a 42RLE that has trouble leaving park.

The Variable Line Pressure Solenoid

The 41TES and the 42RLE-VLPS are known to produce a “Line Pressure to High” code P0869 due to defective TCM/PCM’s immediately after a 2-3 shift. When this call comes in on our help line, we ask the tech involved to run some tests so we can be certain that a defective computer is the cause. Being a pattern failure, a repair tech can be as costly as buying a computer that doesn’t fix the problem and makes for a bad day.

Continuity Conundrum

We spend a great deal of time helping installers with electronic-circuit codes for shift solenoids, PC-solenoid codes, input and output speed sensors, and pressure switches. Nearly all vehicles have issues with circuit codes. The focus of this article will be on Chrysler transmissions, as they seem to have more of these types of concerns than other vehicles.

Two- and three-pin harness connectors have been used for quite some time, and they have always been a primary source of circuit problems. The issues with them seem to be getting more prevalent since the vehicles that use them are aging. Loose pin fit and corrosion are the primary causes found with them, and cleaning with a heavy base (baking soda, for example) and a mild steel brush will usually dissolve the corrosion.

Know Your Patient

One would think the easiest part about working on transmissions would be identifying the model you are working on. Nowadays, unfortunately, it’s not always that easy. I was helping via e-mail a technician on a transmission forum who reported having issues reaming a late-model Chrysler FWD valve body. Both he and I were thinking 41TE (A604), but that turned out to be incorrect. What he was working on was actually a 41TES, also known as 41TE VLP.

42RLE: 1st-Gear Shift Shuttle in Drive

This article, yet another pointing out cross-connect scenarios, has to do with the 42RLE input-shaft and output-shaft speed sensors.

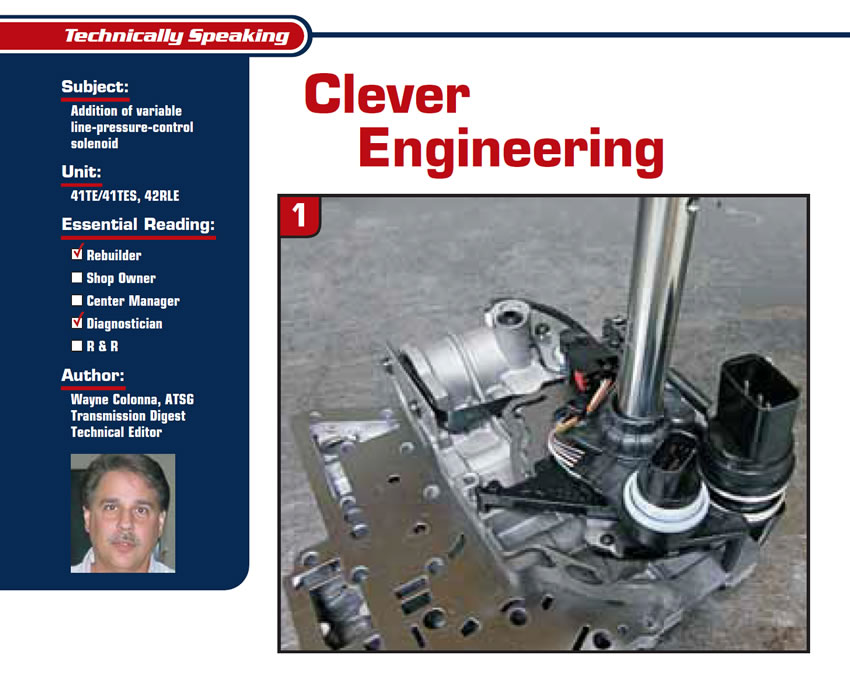

Clever Engineering

Starting with the 42RLE in 2005, followed by the 41TE in 2007, the engineers cleverly redesigned the valve body to accommodate a variable line-pressure-control solenoid and transducer. Figures 1 and 2 shows how these additional components are situated on the valve body with the 41TE transmission. This also required an additional pass-through case connector, resulting in changes to the case as well.

You Can’t Rely on the Relay

Chrysler’s 41TE transmission has been in use since 1989, the 42LE since 1993, the 45RFE since 1999 and the 42RLE since 2003. With each of these transmissions having similar electronics, they also have similar diagnostic codes and testing consistencies.