Up to Standards

- Subject: Design, operation and troubleshooting

- Units: NVG 120, NVG 245 transfer cases

- Vehicle Applications: 2006-09 Chevy Trailblazer & GMC Envoy; Jeep Cherokee

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Contributing Editor, Rockland Standard Gear

There are some very simple things that are very difficult to understand and comprehend. For example, everyone knows how to use a zipper, but no one understands how it works. We live on a planet that has gravity, which operates 24/7. I still can’t get my mind around how it works. Sure, I know if I drop something it will fall to the ground, and things that are on the ground, like rocks and trees and dirt, stay there. It gets complicated, though, when you want to understand what generates gravity.

For instance, our planet is about 25,000 miles in circumference and is making one revolution in roughly 24 hours, which means it is turning at more than 1,000 mph. Why doesn’t everything simply fly off the surface into space? Centrifugal force should make that happen, but luckily for us it doesn’t.

Everything on earth is composed of atoms, which form molecules of matter. They have a nucleus around which varying numbers of electrons rotate. Simple enough in concept but really hard to fathom that the floor you are standing on, or the building you are in, is composed of particles that are constantly moving but remain a solid. Greater minds than mine will have to work this out, but seemingly simple systems require a lot of engineering to create and a lot of understanding to diagnose.

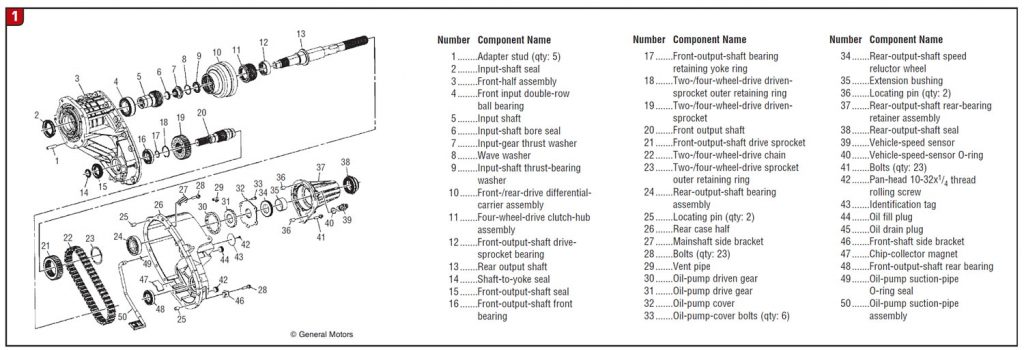

Such is the New Venture Gear 120 transfer case (Figure 1). This one-speed all-wheel-drive unit has no electronics to operate, and no internal clutch pack or viscous coupling. It was used in Chevy Trailblazers and GMC Envoys from 2006 to 2009.

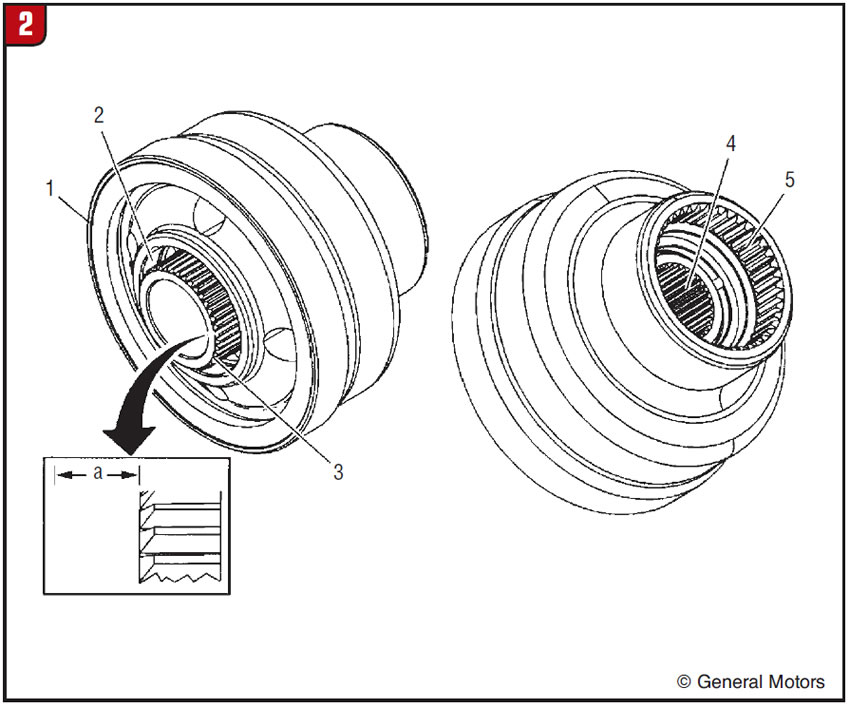

Requiring no driver input, the unit uses an internal planetary-type differential (Figure 2) to bias torque between the rear and front axles.

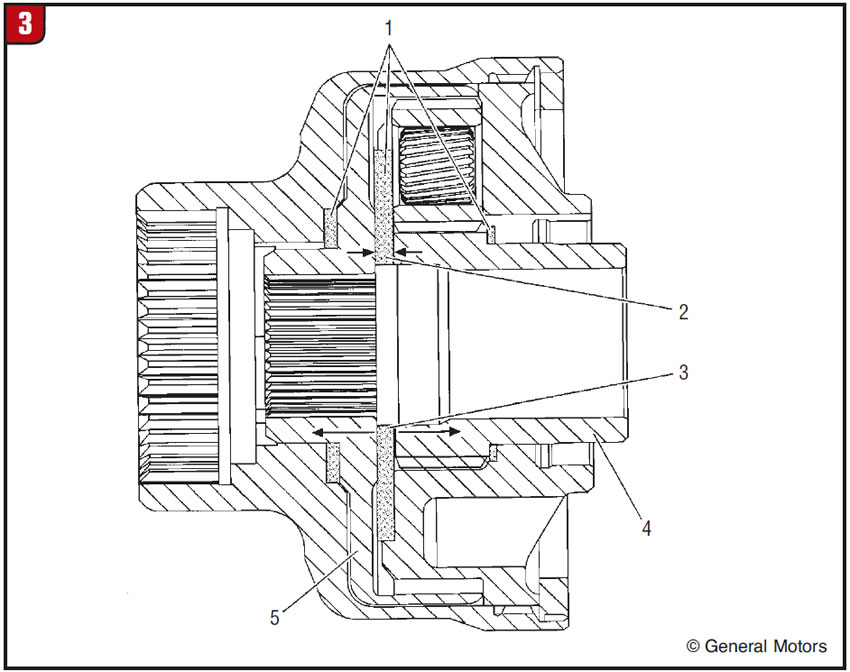

The planetary differential is not a serviceable item and if damaged must be replaced as an assembly. It can be disassembled and it has a sun gear, planetary pinion gears that are basically worm-drive design, and a ring gear (Figure 3).

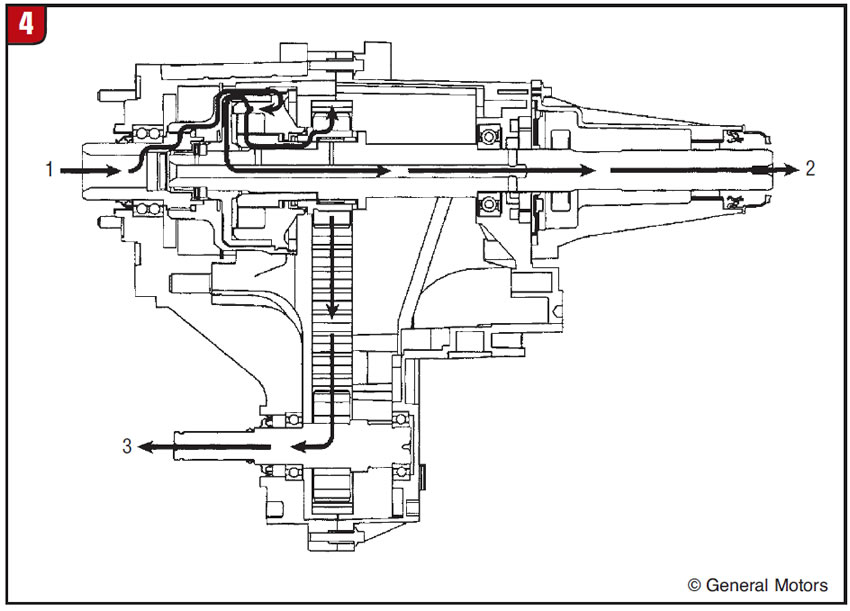

The unit operates much like an open differential in a drive-axle assembly and allows torque to be biased between the front and rear axles. Under normal driving the torque is biased 67% to the rear wheels and 33% to the front wheels (Figure 4).

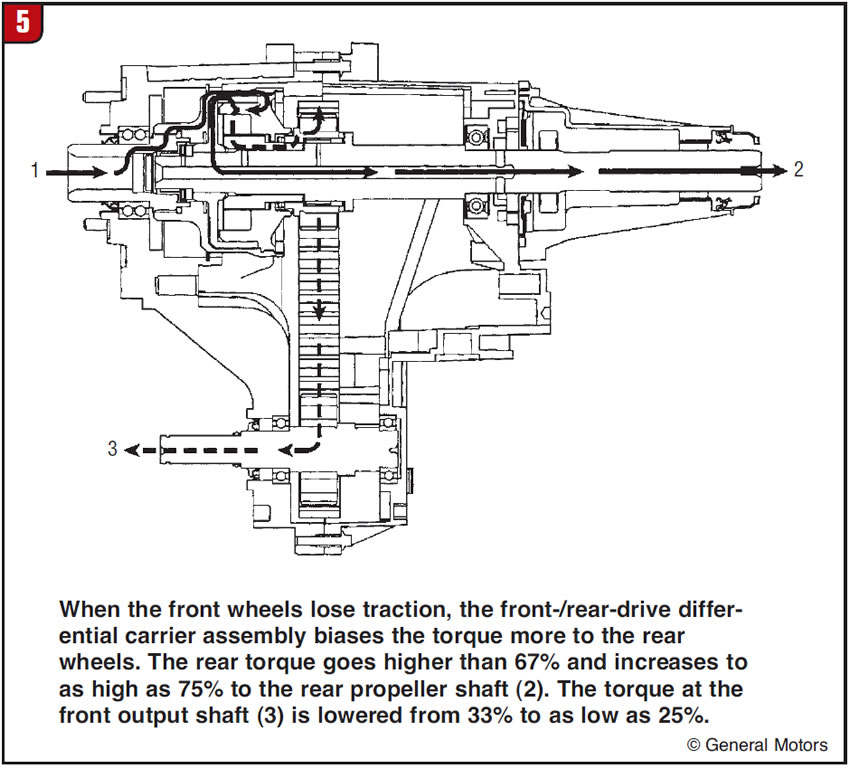

If the front wheels lose traction, the torque bias will go from baseline to 75% rear and 25% front (Figure 5).

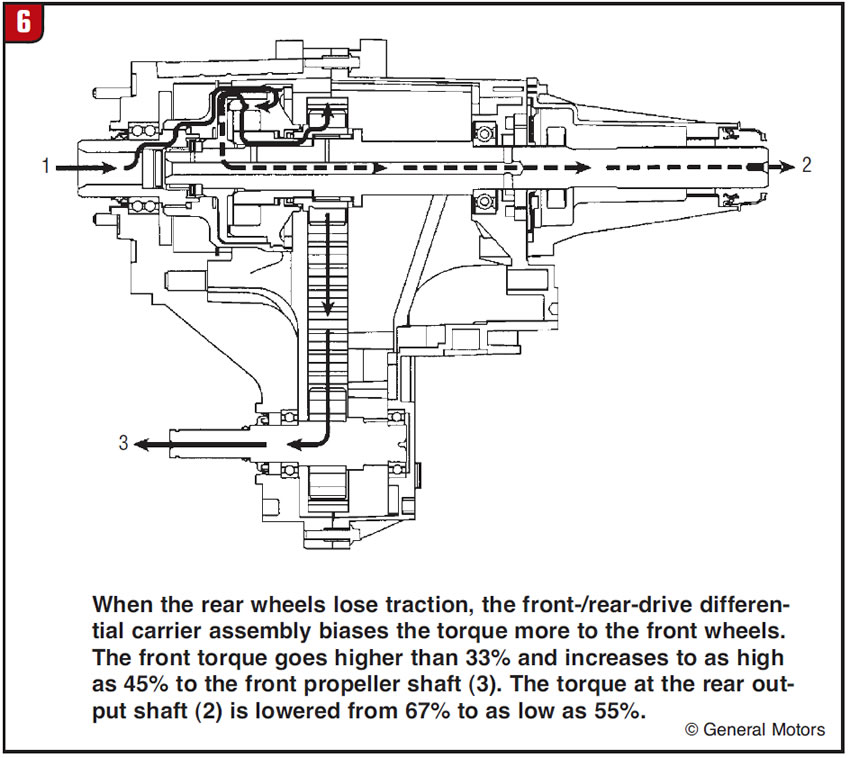

If the rear wheels lose traction the unit will bias torque to the front wheels at 45% and 55% to the rear (Figure 6).

Certain precautions need to be followed to avoid damaging the differential by over-speeding it. These units cannot be operated with one driveshaft removed, they cannot be towed with two wheels on the ground, they cannot be driven on a doughnut type of spare for more than a few miles, and they CANNOT be driven on a lift with the wheels off the ground. Doing any of these will over-speed the internal differential and you will wind up with a pile of melted junk – and a large hole in your wallet.

In operation the differential assembly under a no-load condition will work similarly to an open-differential carrier. Under torque load, thrust forces generated by the helical gearing produce friction, and the friction results in a limited-slip type of action. The sun gear #4 and ring gear #5 in Figure 3 will rotate together under coast torque and will move apart under drive torque, adding pressure to special thrust washers (#1) that increase the level of friction, causing the differential to start to lock up and increasing torque transfer to the wheels that need it.

Wheel slip or differentiation is not required to distribute torque properly; the design of the gear train produces the locking capacity. If it is capable of transmitting torque it is operating correctly, but there is no true way to test this on the bench. What you can do is inspect it for heat discoloration, damaged splines, rough operation of the internal and external splined components by rotating them, and excess axial play of the sun gear at “A” in Figure 2. If the axial play (front to back) exceeds 0.030 inch, get a new differential.

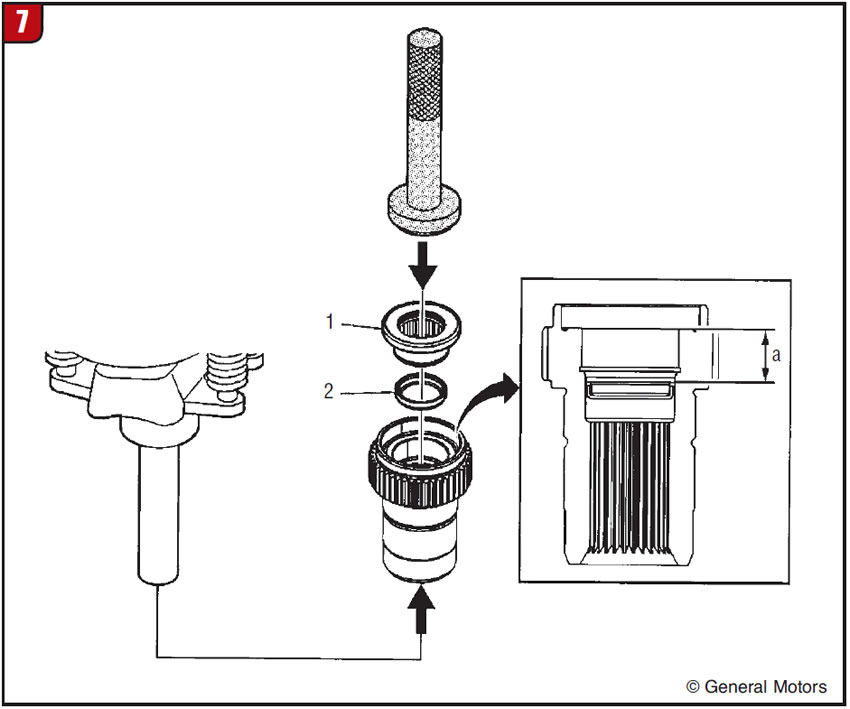

The 120 uses a gerotor-type oil pump to pressure-lube the rotating components driven by the output shaft. When disassembling one of the units, take note of the bearing setup between the input gear and the differential assembly (Figure 7), because it is easy to screw up the reassembly. The input gear has a bearing on top of it that is pressed into the gear. Below that bearing is a seal that keeps transfer-case fluid from entering the transmission through the input gear. Do not remove this bearing unless it is damaged. On top of that bearing will be a wave spring that separates the differential thrust bearing from the input. We have found through experience that because of the operating environment of all-wheel-drive units, it is smart to replace the chain every time you rebuild one.

This is a really simple unit with very few operating parts, but very difficult to diagnose unless you know how it works. Victory loves preparation.

I wish all of you a happy, healthy holiday season and prosperous New Year.

Inspect the Whole Vehicle

I repeat, ad infinitum, how important it is to inspect the whole vehicle before and after any repairs. This should be the must-do routine for every shop. We have many separate but connected systems that all must work in unison for the vehicle to operate as designed.

We had a good customer who went through a long ordeal trying to repair a 2004 or later Jeep Cherokee with an NVG 245 transfer case. After he spent an agonizing amount of time trying to get it to work properly, we suggested that the problem was not in the transfer case. The technician finally realized that the electronic solenoid that engages the front differential was broken and could not engage the front axle in 4×4. Take a look at the solenoid in Figure 8, and save yourself a lot of heartache. Go over the whole car before you jump in with both feet. The time you invest in a good examination will save you five times as much by not having to chase the problem afterward.