Up to Standards

- Subject: Diagnosis and service

- Unit: NVG 247

- Vehicle Application: 1999-2004 Jeep Grand Cherokee

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

The New Venture 247 transfer case was used in the Jeep Grand Cherokee (WJ) vehicle in the 1999 to 2004 model years. Nobody throws away a Jeep, and these units create a lot of repair work and parts sales. They also generate an inordinate amount of tech calls as a result of the problems with the design and misunderstood theory of operation. This article will concentrate on the areas that cause shops the most trouble in diagnosis and repair.

The 247 is an evolution of design that started with units using viscous couplings. The viscous coupling would react to differences in wheel speed between the front and rear axles and send power to the wheels that needed it until the slippage stopped and the shaft speeds equalized front to rear. These units were extremely susceptible to differences in tire size front to rear, and tires with more than 1/4 inch difference in circumference would have the viscous coupling working overtime to correct a slip that wasn’t there. This failed the viscous coupling quickly, creating another expensive repair.

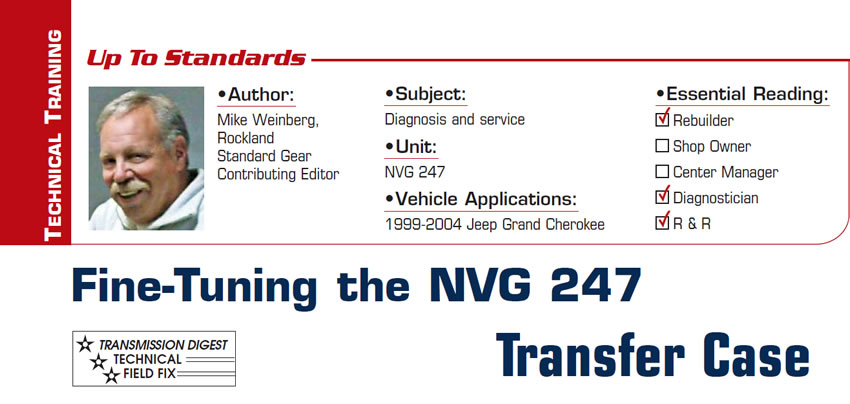

To advance the engineering, New Venture replaced the viscous coupling with what it called a “progressive coupler” or pump coupler (Figure 1). Under normal road conditions most of the torque is applied to the rear wheels; when a speed difference between the front and rear wheels occurs, the progressive coupler acts as a differential to send power to the axle with better traction, eliminating wheel spin and restoring control with no driver input.

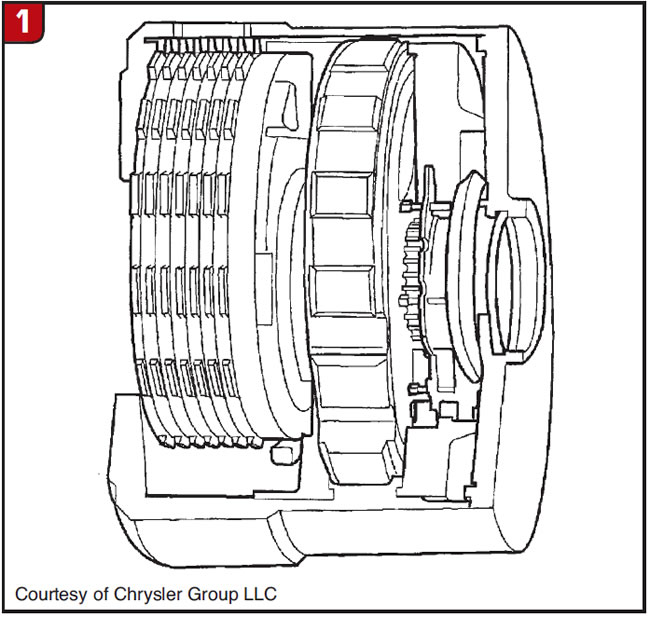

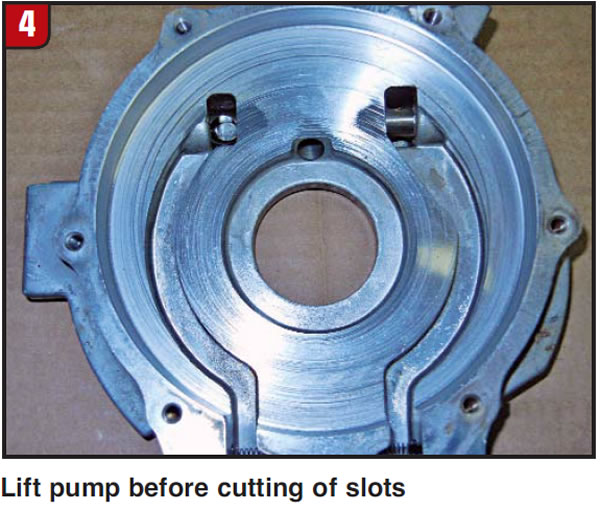

In the NV 247 there are two gerotor-type pumps. The main, or lift, pump (Figure 2) takes fluid from the sump and forces it through the bearing bores and supplies the pump coupler or progressive coupler with pressurized lube. The coupler is a sealed, non-serviceable unit that contains a second gerotor pump and a clutch pack, piston and pressure plate. The assembly acts as a differential, and when there is wheel slip the difference in shaft speeds puts the pump to work pressurizing the clutch pack and sending power to the front axle. When the shaft speeds equalize, the pump stops working, the pressure bleeds down and power reverts to the rear wheels only.

Sophisticated orifices and valves inside the coupler make this happen in an orderly fashion, and these units suffer badly from dirt and worn-out or insufficient lube. This creates an expensive repair, as the progressive coupler must be replaced as an assembly. This part (# 5012329AA) sells at the dealer for about $686, and the failure rate is high enough for aftermarket companies to tool up to manufacture it at a price in the $363 range, a savings of about $320. What’s not to like?

However, there are issues that need to be resolved here, as there are timing differences between OEM and aftermarket progressive couplers. In our research we have found that the OEM coupler needs about three or four revolutions to activate. That window is designed to compensate for slight normal differences in wheel speed. The common complaint with the aftermarket coupler, which has a more instant-on timing, is binding on turns, especially when it’s new with maximum coefficient of friction in the clutches. This will create an issue for you with a customer who has just plunked down his life savings to pay for the repair.

On top of that, many of the WJ-series Jeeps were built with what is called Quadradrive. This system uses progressive-type couplers in the front and rear differentials to make them limited-slip. The differentials in both axles also use hydraulic pressure to apply the clutch packs for limited slip, and they are extremely prone to worn-out fluid or dirt and contamination from off-road use. Do not just condemn the coupler in the transfer case without making sure both differentials are functioning properly and are full of the special fluid required and that the fluid is not burnt or oxidized.

Another issue occurs when these differentials are serviced and the builder applies too much RTV to seal the case. Excess RTV can fall off internally and clog the orifices and create a fully locked differential that is unable to bleed off pressure. This will cause enough of a bind to literally stop one of these vehicles in a turn.

So we want to use an aftermarket progressive coupler in the transfer case, but we do not want to deal with a binding condition on turns. Here are the steps to take to solve this problem and get the customer happily on his way:

- Always measure the circumferences of all four tires with a stagger gauge ($50). Any differences of more than 1/4 inch will require tire replacement, as this alone can fail the progressive coupler.

- Disassemble the gerotor lift pump for cleaning and inspection. This assembly is also sold only as a complete assembly; no service parts are available.

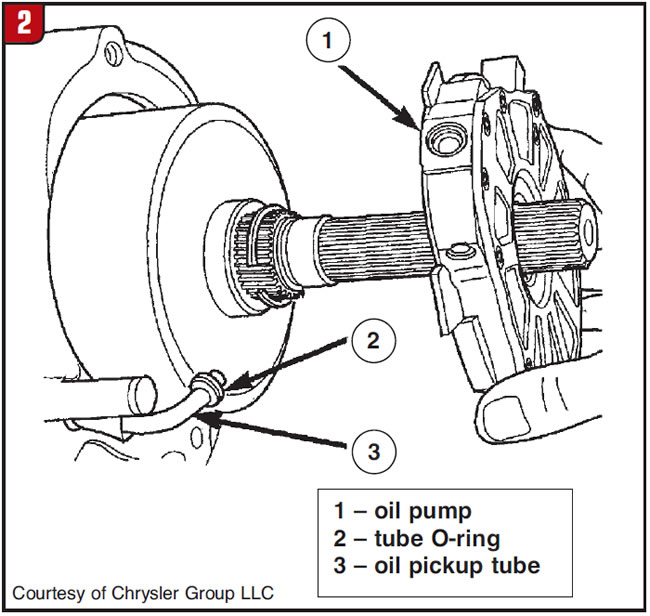

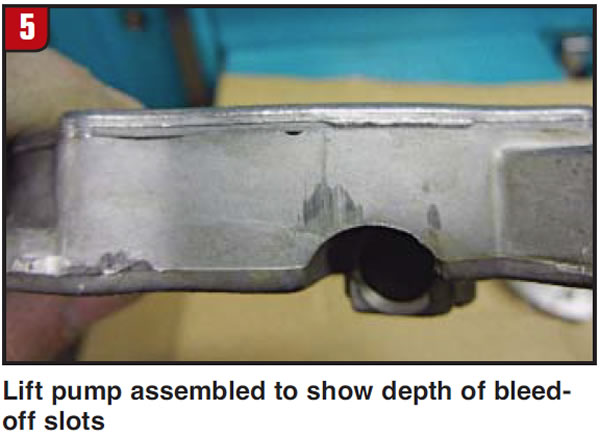

- Using a die grinder or a hacksaw blade, cut a bleed notch (about 1/8 inch) in the pump surface (Figure 3). This allows oil to bleed off more quickly and cures any timing problems that may influence the release rate of the progressive coupler. Reassemble the pump.

- Make sure to use the correct fluid for the 247, and when installing either OEM or aftermarket progressive couplers soak the unit overnight in the correct lube to get the clutches wet and remove any air trapped in the friction material or coupler.

- Road-test the vehicle making moderate to tight turns for a few miles to make sure that the coupler is releasing properly. Some slight initial binding is normal but should go away within a few miles of driving.

Understanding the theory of operation, being aware of the sensitive nature of the Quadradrive system, and recognizing the critical importance of tire sizes for correct operation of the vehicle will go a long way to sorting out your diagnosis and repair problems.