Bonus Tech

- Author: Devlin Callihan

- Subject Matter: Diagnosis

- Unit: 62TE

- Vehicle Application: 2008 Chrysler Town and Country

- Issue: No movement

A 2008 Chrysler Town and Country with a 3.3-liter engine and 62TE transaxle with 80,000 miles on the odometer came in with transmission issues. The van wouldn’t move at all.

I thought it was pretty straightforward, so I started with a multi-point inspection. All fluid levels were good, and the transmission fluid was nice and red.

Code retrieval revealed codes for input- and output-speed-sensor circuits and EGR position stuck closed. No movement explained the input- and output-sensor codes. The EGR code in this instance was caused by a defective EGR.

Diagnosis of the transmission was next. A lack of input speed on the scan data could indicate a bad sensor, but since the vehicle didn’t move at all I doubted that the sensor was bad.

I had the transmission removed. When I removed the torque converter, I found that the input splines were stripped, as I expected. I went ahead and rebuilt the transmission, though, because of other concerns.

The unit was filled with fluid and taken for a test drive. Upon return, the technician said the transmission was slipping and bucking between shifts. The first thing I did was to look for a check engine light, which was not on (yet). So I went for a test drive. The 1-2 shift was all right, but during the 2-3 shift, engine speed started fluctuating and the check engine light came on. We checked for codes again and found one for an intermittent crank-position circuit. I already had my suspicions as to the problem, but now it was time to prove it with the least possible fuss.

I didn’t want to risk damaging the rebuilt transmission by driving the vehicle, and I was almost certain that the problem was a crankshaft-position issue, especially since it indicated that during a shift.

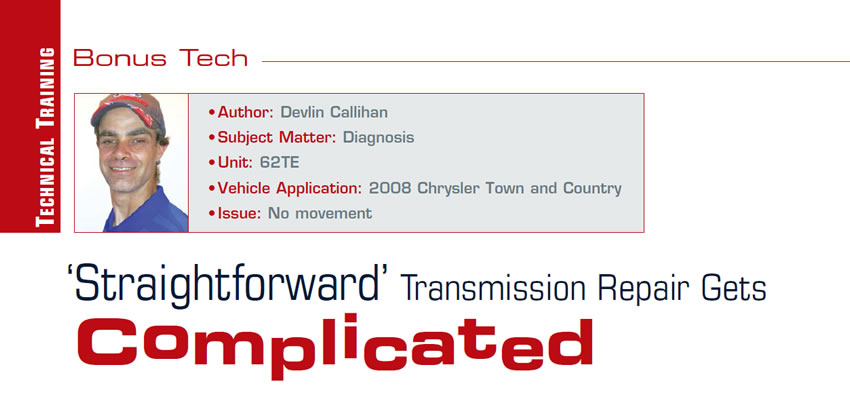

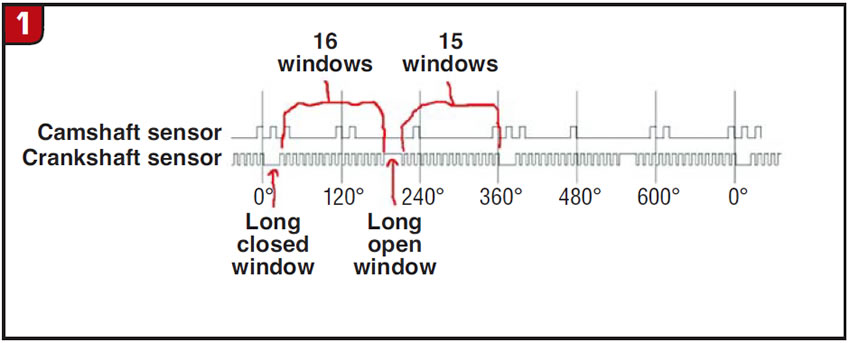

For those who don’t know how this crankshaft-position sensor works, it is a three-wire magnetic-pickup type. One wire is a 5-volt reference, the second is the sensor ground and the third is the signal wire to the powertrain control module. The sensor counts the windows on the tone ring, which is attached to the flywheel, to determine the position of the crankshaft and which stroke the crank is on.

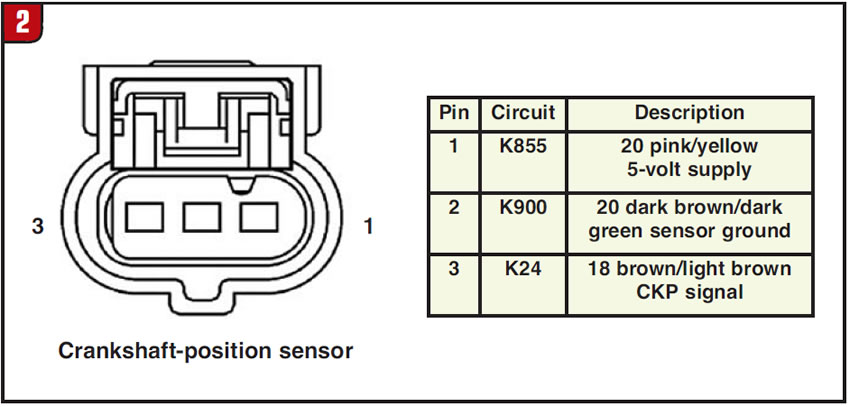

Since visually inspecting the flywheel or the crank sensor on this van requires removing the starter and using mirrors or a bore scope, I decided to electronically scope the crank sensor. At idle and at high engine speed the pattern looked great, with no glitches or dropouts. But while driving the vehicle and with the shifts acting up, I was able to capture the problem. The scope revealed that I lost two windows on three consecutive crankshaft rotations, all in the same location on the flywheel – about 40° after top dead center of the intake stroke and the same on the exhaust stroke.

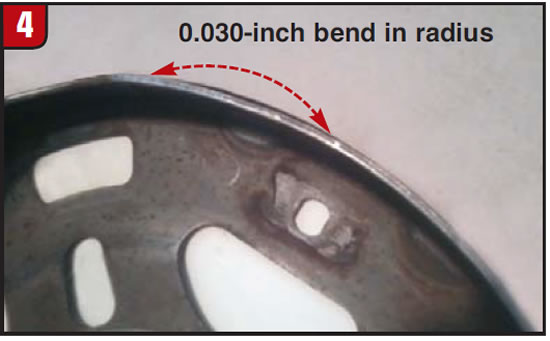

That eliminated everything but flywheel damage, and I knew which part of the flywheel to check, so I had the R&R guy remove the transmission again. Nothing really stuck out until I looked closely at the area the scope had indicated. I cut a piece of cardboard to the radius of the tone ring so the bend would be easier to see in the photo.

The transmission on this van is a tight fit, and when the technician installed the transmission the bellhousing hit the outer tone ring of the flywheel and bent it. Using my scope made pinpointing the damaged area much easier than trying to use mirrors, especially since the dent is hard to see even with the flywheel removed.

Devlin Callihan, ASE and Ford master technician, AAMCO Master rebuilder and Allison automatic specialist, works at AAMCO Transmissions & Total Car Care, Hightstown, N.J.