R&R Tech

- Author: Barry Bartlett, diagnostician

- Subject Matter: Reviewing solenoids and frictions elements

- Unit: 4L60E

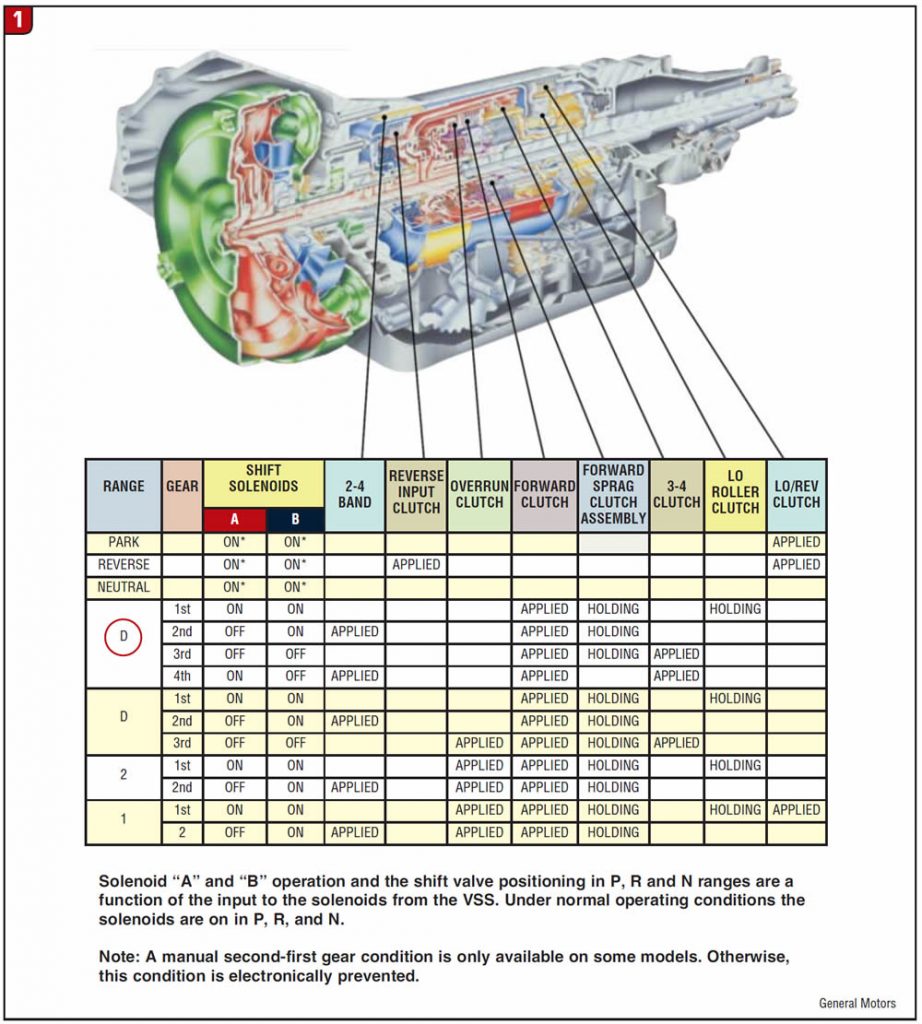

One of the best and easiest tools that I use almost daily for diagnosing transmission problems is Passbook or application-chart information. When I have a shifting issue, a review of what solenoids and friction elements are applied in each gear can let me see what areas of the transmission the problem may be caused by, so I can then differentiate whether there is an electrical or mechanical issue causing the symptoms.

I will use the 4L60E transmission for the following scenarios (see diagram).

Third-Gear Neutralization

If the vehicle is shifting to first and second gear and feels like it neutrals when third is commanded, a review of the solenoids shows that both are on for first gear, so I know that both are turning on. When second gear is commanded, shift solenoid A (SSA) turns off. In third gear both solenoids are off, so when I feel the neutral condition, it is a good sign that shift solenoid B (SSB) is turning off so I can then conclude that both solenoids are working properly.

Testing further, I know that on the shift from second to third gear that the 2-4 band turns off and the 3-4 clutch applies. Next, I shift to manual second while increasing the vehicle speed until about 40 mph, then shift to overdrive and let off the gas. If I have a second-gear ratio when fourth gear is commanded, it will reveal the cause: the 3-4 clutch is not holding. Referring to the chart, I see that the 2-4 band applies at this point. If the 3-4 clutch does not hold, the transmission remains in second gear because the forward clutch and the 2-4 band are holding, thus indicating that the 3-4 clutch is not.

No Movement from Stop

If I have no movement from a stop I can test to see whether the forward clutch is bad, or if the forward sprag clutch is not holding, by shifting into manual low. If there is now movement, the forward sprag is bad because the overrunning clutch holds the sprag, but if it still does not move, then it is the forward clutch causing the concern.

No Second or Fourth Gears

If I am missing second and fourth gears but all other gears are OK, the cause points to the 2-4 band not applying. Many times I have had customers complain that their transmission stays in first gear for a long time before it finally shifts, and some will report that they have to let off the gas pedal in order to get it to shift.

They might think that it is then in second gear, but they are actually in third gear and may not notice that there is no upshift into fourth gear.

Remember that in first gear both shift solenoids are on and in third gear, both are off. That would indicate that the solenoids are working OK and point to a friction element, and as the chart shows, the common element applied in second and fourth gears is the 2-4 band. The 2-4 band holds the sun shell. Sometimes the sun gear will break away from the sun shell on the 4L60E units and you will lose second, fourth, and reverse gears that then require the replacement of the sun shell.

Forward but No Reverse

What if I have all forward gears but no reverse? A look at the application chart shows that the reverse input clutch and the low/rev clutch engage to engage reverse gear. An easy way to test this is to accelerate to about 20 mph and pull it into manual low to see if you have engine braking when you let off the gas. If engine braking is working, that indicates that the low/rev clutch is correctly holding the sprag clutch from overrunning. This would indicate that the reverse input clutch is the cause. If you do not have engine braking, it points to the low/rev clutch being bad and preventing reverse. It is good to confirm the integrity of a sprag clutch before performing a rebuild, because you may not be able to tell when the transmission is disassembled and you are holding it in your hand.

In addition, the chart can be helpful if you suspect a component problem. For example, a review of the solenoid application chart will show the outcome if SSA is not turning on: Second gear starts and the transmission will shift into third, but if SSA is not turning on you will also have no fourth gear. Second and third gears would be the only forward gears that function.

If SSB is not turning on, the solenoid chart shows that the transmission would have fourth-gear starts, and manual second and third gears at about 30 mph. When shifting up from manual second to third or overdrive gear, I will have fourth gear when the computer commands because the SSA is working.

What is the effect if there is no power to any of the solenoids? We would have third gear with no upshift or downshift when in drive. Manual second would function because it is hydraulically shifted into second gear without solenoids, but in drive or overdrive we would have only third gear because no solenoids are turned functioning. I can then know to look for electrical/control problems.

When there is no power to the solenoids it will generally set multiple solenoid codes on any transmission, so check fuses and ensure there is power through them, then check for power at the transmission connector. If there’s no power at the fuse, you could have an ignition-switch problem (common on Chevrolet), but if no power at the transmission fuse, check your power distribution to identify where the power is sourced to the fuse.

On most GM trucks and cars you can actuate the solenoids with a scan tool and listen for the solenoid to click (both solenoids can be tested in this manner) and let you know that they are working and that the computer has the capability of turning them on and off.

Some vehicles will shut off power to the transmission when it has a code set by turning off the relay that supplies power to the transmission, so be sure to look for codes that could be causing a limp-mode condition. This is commonly seen on 604 Chrysler transmissions, where in limp mode it will shut off the relay leaving reverse and second gear only. Look for codes and see if there is a speed-sensor, pressure-switch problem, or some other issue causing the limp-mode condition.

It is also a good idea to monitor the status of the solenoids for the proper gear, because I have had defective computers give false information showing that they are calling for a certain gear on the scan tool, but yet not turning on the solenoids that are needed for that gear. I often tap into the wires with a lab scope, voltmeter or test lights to make sure that the computer is turning on and off at the correct time.

Many transmissions now use pulse-width-modulated solenoids, so instead of on and off, the chart may show high and low pressure and/or high or low amperage. Also you might see on the application chart “N.O.” which stands for “normally open,” and “N.C.,” which stands for “normally closed.”

There are several sources to obtain the Passbooks and charts referenced in this article. Collecting application charts and saving them for future reference can help with the diagnosis of any transmission, and can make your recommendation for repairs much easier. As you become acquainted with and review application charts, you will find diagnosing transmission shift issues easier and quicker to pinpoint.

Barry Bartlett has over 45 years of automotive experience. He has done everything from managing, owning, and operating his own general repair facility to working in the transmission industry. He’s a ASE Master tech with L1 advanced level diagnostics, the highest level of certification available.