Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Implications of Mechatronics

- Issue: Protocols for vehicle controls

In addition to dealing with the transmission evolutionary variables mentioned in Part I of the series, the transmission repair industry must contend with much more currently, as well as future changes that will occur.

Despite the efforts of organizations like SAE (Society of Automotive Engineers), the OEM’s have failed to standardize certain aspects of vehicle operations. Several different protocols exist that the OEMs use for OBD-II compliance. For a period of time, there were five basic protocols used by most OEMs to control their vehicles. Today there are a lot of different protocols to control an array of components from powertrain to airbags to audio/visual.

Diagnostics, testing equipment and repair will vary based upon the system, which is why it’s important to know what a particular scanner can accommodate.

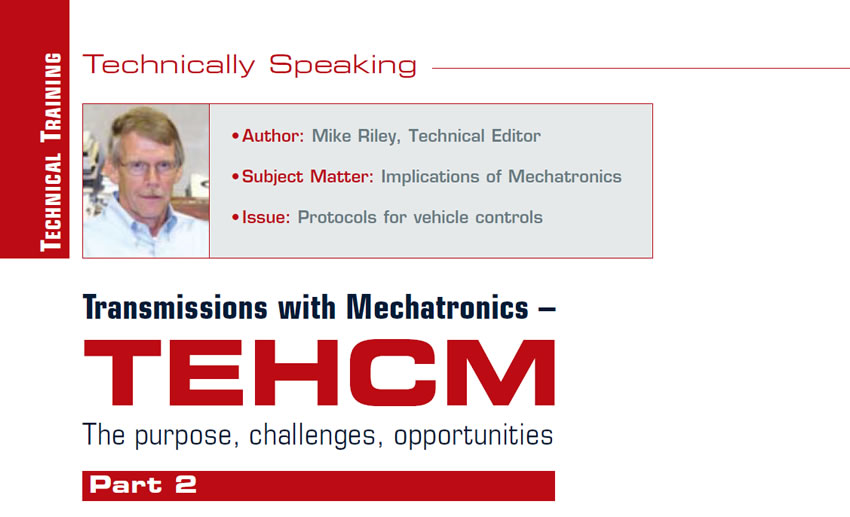

The basic protocols are as follows:

- SAE 51850 VPW (variable pulse width): Primarily used by GM. High voltage is 7V and has a communication speed of 10.4kb/sec.

- SAE 51850 PWM (pulse width modulation): Primarily used by Ford. High voltage is 5V and has a communication speed of 41.6 kb/sec.

- ISO 9141-2: Primarily used by Chrysler (earlier models), European and Asian vehicles. Communication speed is 10.4kb/sec and uses k-line/L-line (optional) with 5-baud initialization.

- ISO 14230-4 (keyword protocol KWP2000), beginning about 2003, is a newer version of ISO 9141-2 with two variants. One variant has a 5-baud init like ISO 9141-2, while the other has a (fast init) and does not use the 5-baud init process.

- ISO 15765-4 CAN-bus (controller area network) – although CAN-bus has been hanging around Europe for more than two decades, U.S. vehicles finally were mandated to use CAN by 2008, and it has become the chosen protocol. There are four CAN variants in use today which are described as II bit or 29 bit ID – 500k baud rate as well as 11 bit or 29 bit ID-250k baud rate.

Although the J1962 diagnostic connector is uniform in shape, the pin configuration will dictate which protocol the vehicle is equipped with (Figure 1).

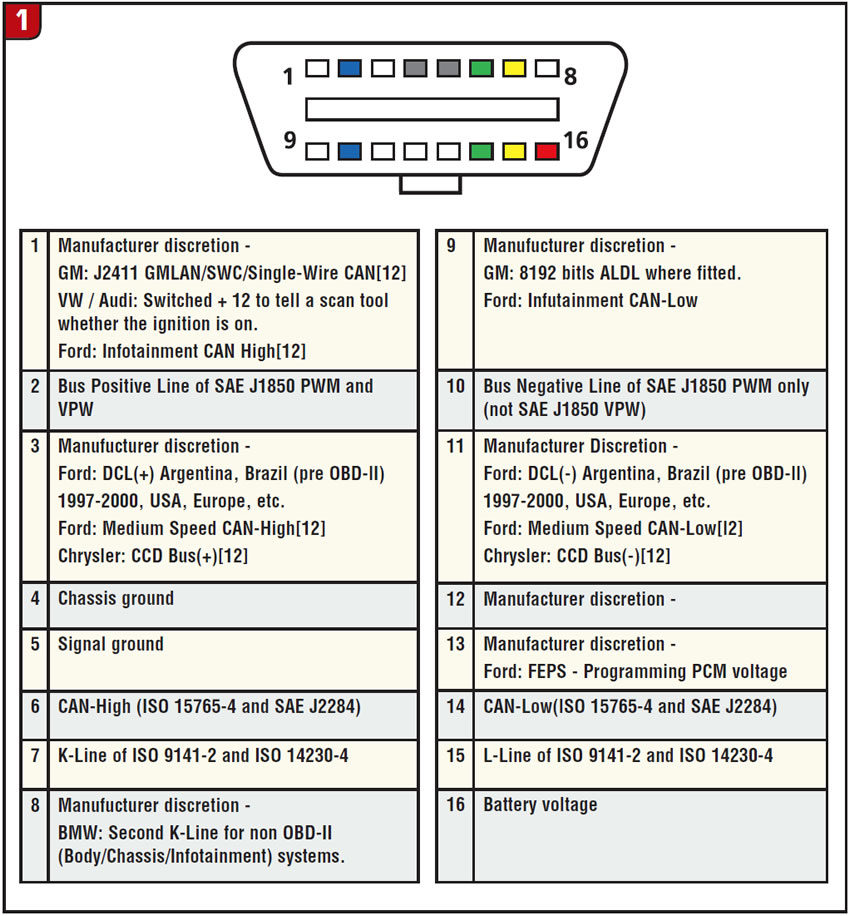

Beyond the basics, manufacturers have the latitude to implement protocols to suit their various demands. Some of the protocols have been around for years while others are fairly recent. The following are just a few:

Beginning in 2010, another game changer happened, Global A/B Architecture. With global applications, standard hand-held scanners may not function too well or not at all. Beyond that, module swapping is almost non-existent because everything is “coded up.” Even reprogramming procedures will vary. “Ain’t progress grand!”

Regardless of the vehicle’s operating system, an issue started to surface years ago, which was the inability to upgrade emissions programming routinely. The EPA and CARB determined that a means to provide updated computer programming to the field was necessary; therefore, it was mandated that by 2004 a standard vehicle interface be developed for use by everyone. The result was a VCI (Vehicle Communication Interface) with the SAE designation of J2534. Drew Technologies, working with SAE, developed the J2534 VCI initially, although today there are several on the market. The J2534 device enables Web-based downloading of updated CPU reprogramming for a variety of issues, regardless if the transmission has a TEHCM or not.

It is increasingly important that these updates are implemented.

Transmissions with Mechatronics

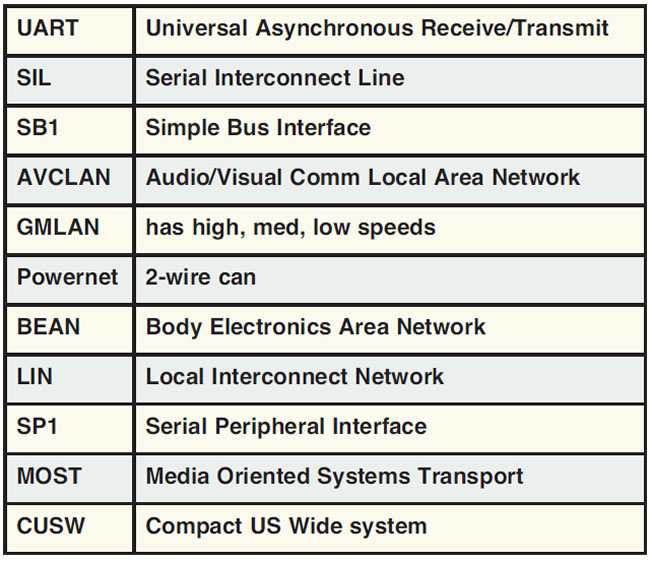

Not all OEMs have made the leap to transmissions with a TEHCM, but there are enough. Currently, this is the list of applications on the street:

Diagnostics/Testing

Ever since electrical components arrived on the scene, the ability to test them has, at times, been a challenge, including transmission stuff. Simple solenoids, sensors and pressure switches were no big thing to test. Take a little bit of voltage/current, add in a ground and combine it with air pressure and voilà, test completed.

As components became more complex, such as PWM or linear solenoids, so did the ability to test them. Pulse electrical signals and special body manifolds for air passages became the norm. Changes, however, were hard to keep up with.

Mechatronics has added yet another wrinkle on certain applications due to solenoids and sensors being incorporated into the same framework with the TCM, such as GM. The 6L80 and 6T40/6T70 TEHCM units are made to limit accessibility of the components. There is hope though. Kent-Moore (Bosch) developed a testing kit that contains a solenoid plate with air fittings, gauge and harness which connect to the vehicle’s system and TEHCM (Figure 2). Using the vehicle, TCM and solenoid functions can be performed.

Kent-Moore also has a signal generator to simulate input/output speed signals if needed (Figure 3). It beats spending over $500 needlessly for a replacement.

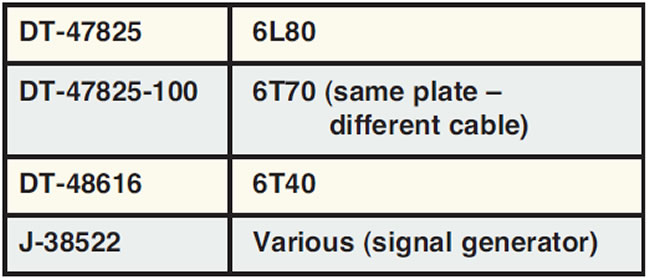

There are four kits:

Over the years, vehicle-system testing has been accomplished with hand-held Scanners such as the Snap-On Scanner and Vectronix Tech II as well as others. Due to the changing systems and protocols, especially CAN and global architectures, it is increasingly difficult for tester companies to respond, which is why diagnosis/testing is going web based.

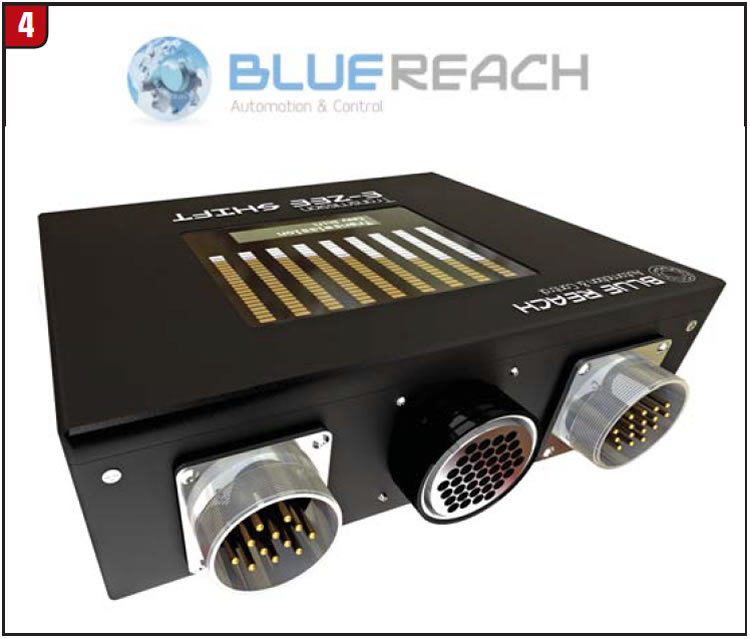

Mechatronic transmissions pose even a greater challenge with the internal TCM being a road block to simple procedures. Experts in the diagnostic-equipment field have been working on this issue for some time now and one such company is Blue Reach Automation. Side stepping CPU safeguards to get at the basics of the system, to enable testing was finally cracked with the release of the E-zee shift tester (Figure 4). The E-zee shift can work with the vehicle, on a dyno, or on a valve body machine.

The test will view CAN signals and detect CAN communication errors, if any. E-zee shift will connect to different CAN structures including vehicles without J1962. The tester will convert CAN signals to a readable format so that the technician knows what is happening.

Beyond the E-zee shift technology, there was a further need for more sophisticated software to help with Mechatronic applications, which is why BlueReach released the Enigma (Figure 5). The Enigma enhances the E-zee shift capabilities with even a better and faster approach. The days of Mechatronic testing are here. Visit www.bluereachautomation.com for further information concerning Mechatronic testing and diagnosis.

Part III of this series will expand on testing options, CPU repair/replacement, and reprogramming.

Special thanks to William Henny at BlueReach Automation for input concerning this article.