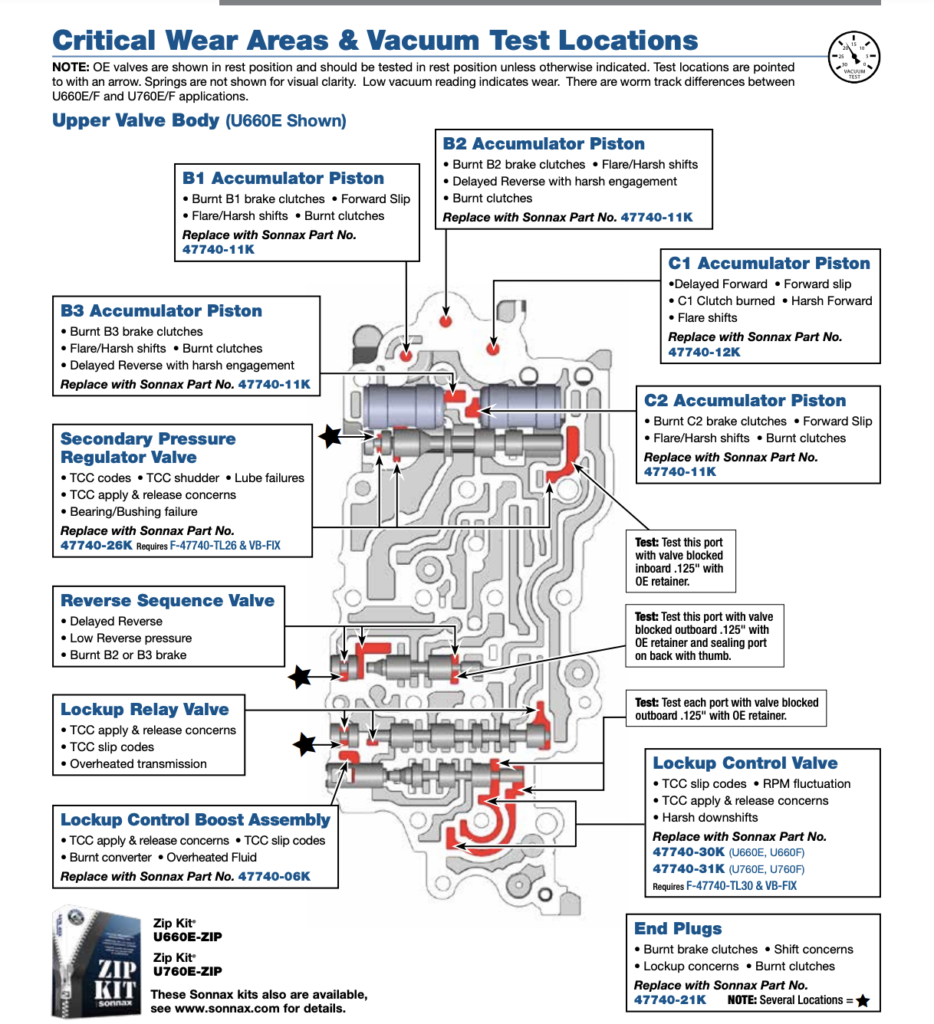

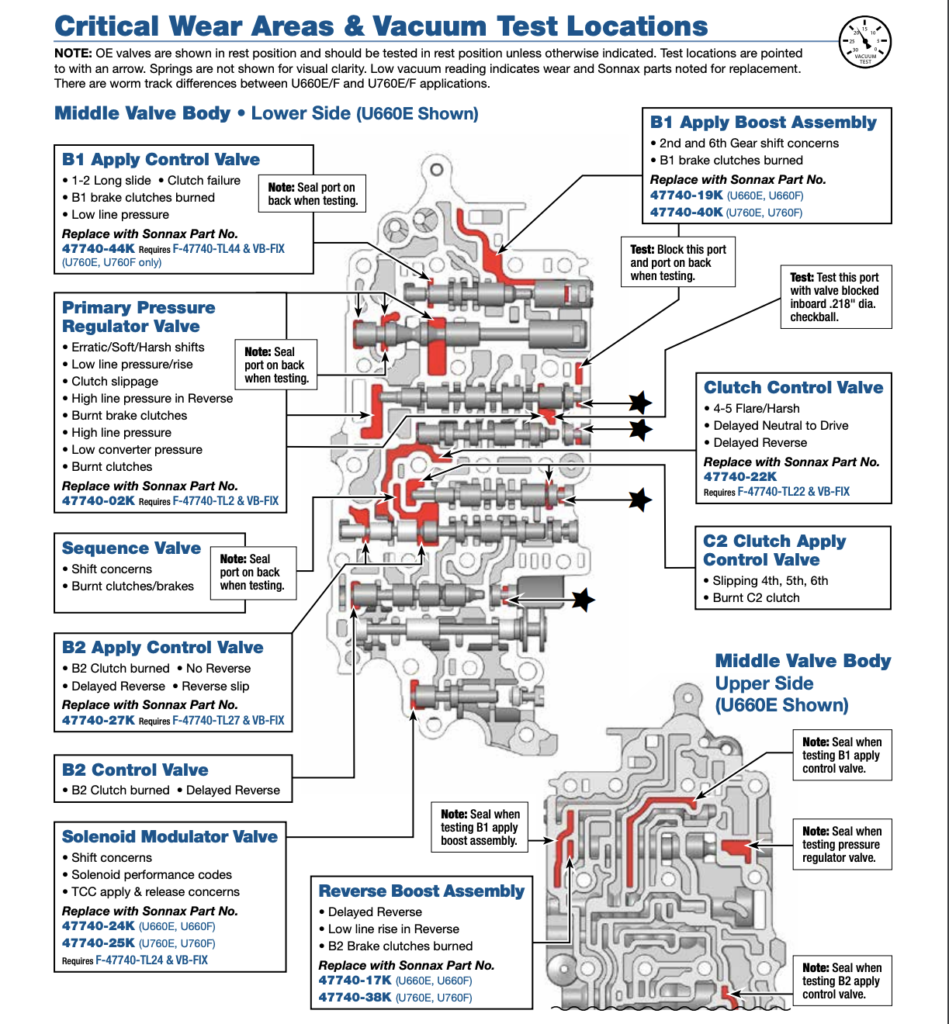

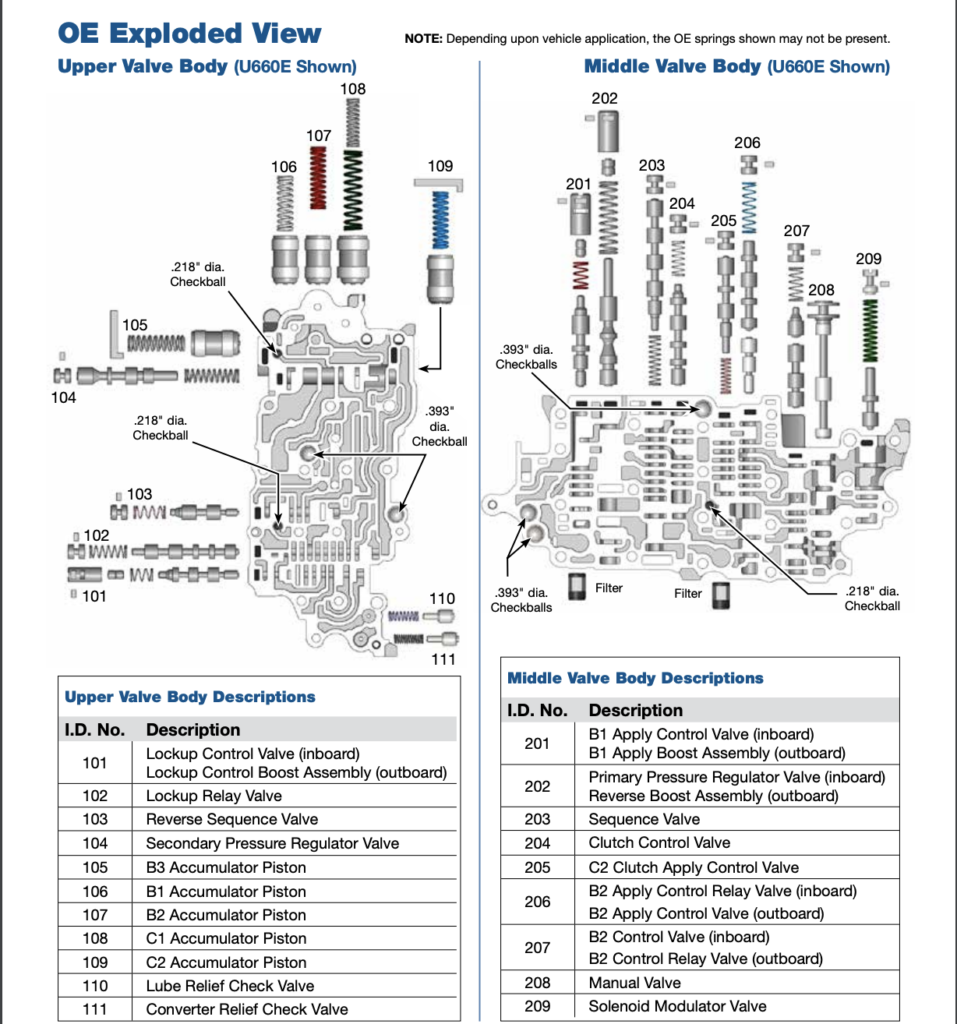

OE valves are shown in a rest position and should be tested in a rest position unless otherwise indicated. Test locations are pointed to with an arrow. Springs are not shown for visual clarity. A low vacuum reading indicates wear.

What should my vacuum test results be?

While a properly calibrated and maintained test stand will give consistent vacuum reading results for a specific circuit and amount of wear, evaluating these results requires establishing your own pass/fail criteria. Variables that influence vacuum readings are the number of spools tested in a captive circuit, spool diameter size, and contact length of the spool within the bore. Pass/Fail standards are specific to your setup and process, but they also must be based on your experience, quality sensitivity, warranty concerns and cost/pricing structure. You should keep a record of vacuum results for each valve body at each tested circuit/port location. This lets you compare results over time to help determine for your shop what an acceptable vacuum reading is for each circuit/port location.

For specific vacuum test parameters, refer to additional information available at www.sonnax.com.