Technically Speaking

- Subject: Flex control of lockup clutch

- Unit: U660E

- Vehicle Applications: Toyota Aurion, Avalon, Camry, Sienna, Venza; Lexus ES 350, RX350

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

Toyota’s six-speed U660E (Figure 1) uses a converter-clutch strategy called flex lockup control. A partial explanation of this flex control strategy by Toyota follows:

During acceleration, flex lockup-clutch control operates when the transaxle is in second gear or higher and the shift lever is in the D, S6, S5 or S4 range position. During deceleration, it operates when the unit is in fourth gear or higher and the shift lever is in the D, S6, S5 or S4 range position.

Basically, it’s the ability to control a partial application of the converter clutch as early as second gear all the way to sixth gear. Once all parameters are met a full application will take place during a highway cruise. Then, during deceleration, it will enter the flex mode, slipping the converter clutch and fully releasing when third gear or lower is commanded.

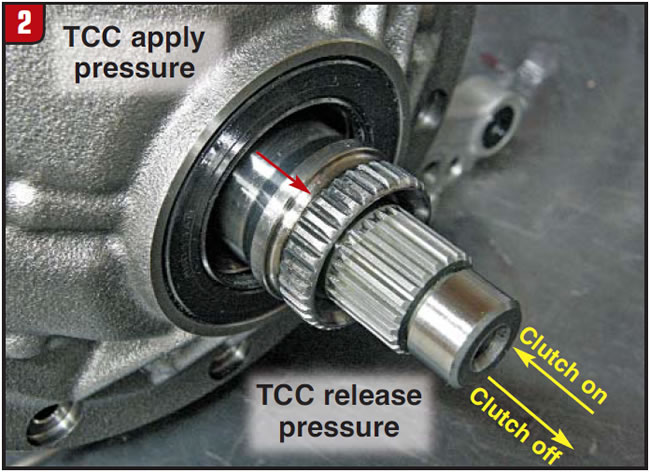

A simple glance at the turbine and stator-support shaft (Figure 2) does not reveal anything unusual. The TCC release passage through the tip of the turbine shaft and TCC apply at the base of the stator-support shaft would normally be assumed.

But upon closer examination with the turbine shaft removed, you can observe an additional passage by the stator bushing used to support the turbine shaft (Figure 3). There you can see that there are several troughs under it.

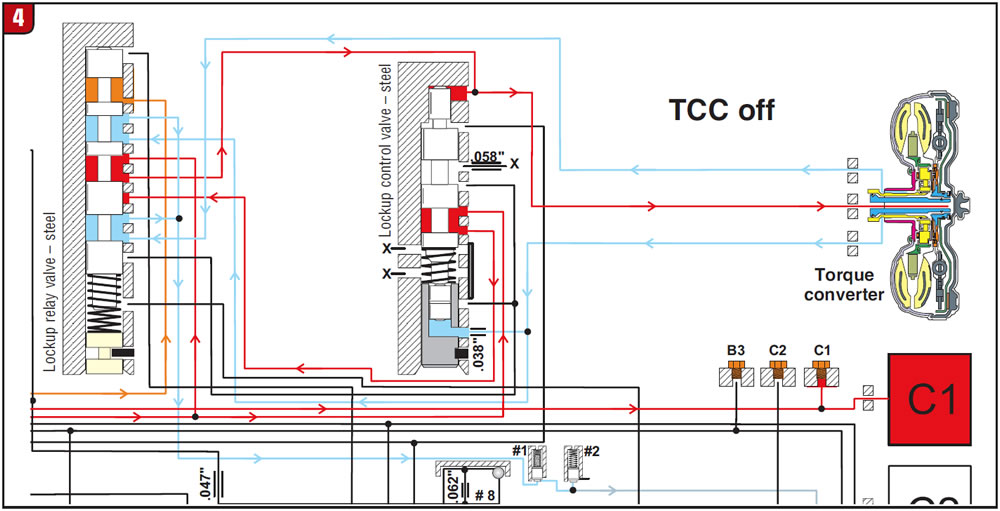

This means the U660E has a three-path converter circuit, which is typically seen in clutch-pack-type converters such as those in the Mercedes 722.6 or 722.9 transmission. But not so with the U660E transmission, for it uses a conventional converter with a single clutch plate. One of the three ports used in this system is nothing more than a typical TCC release circuit supplying fluid pressure to the face of the clutch plate through the center of the turbine shaft. When this circuit is exhausted the pressure on the back side of the plate applies the clutch against the cover. What is different with this flex control is the way the pressure that applies the clutch is controlled.

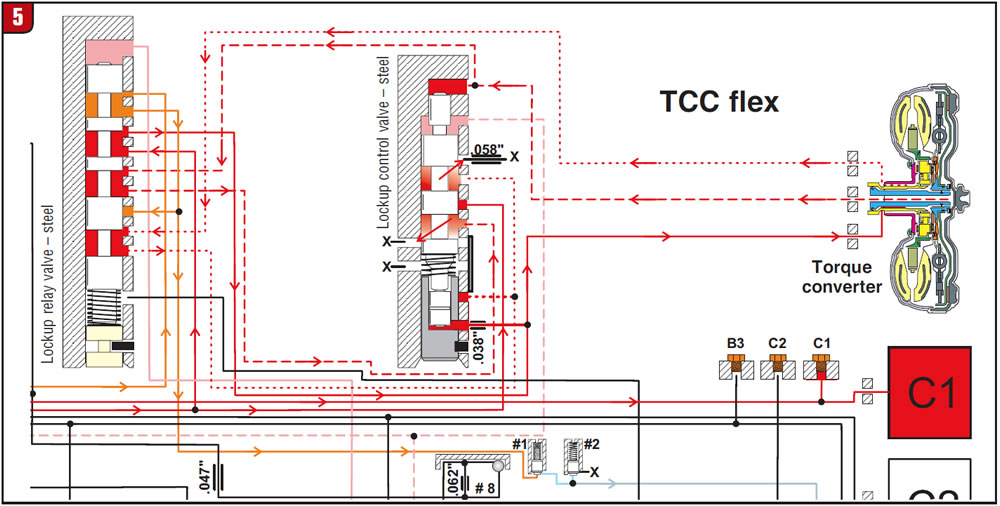

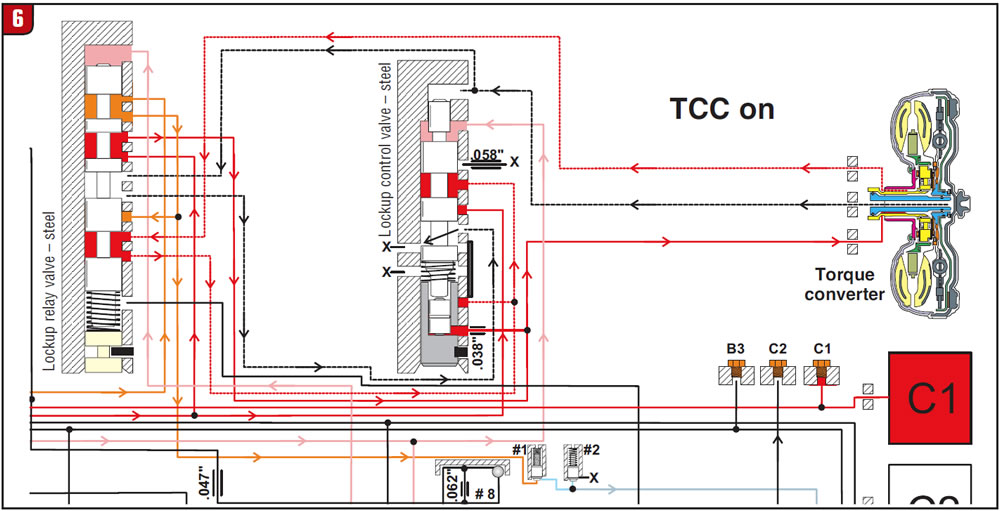

Typically the apply pressure is controlled by a TCC regulator valve and applies the clutch plate like a piston where the regulating apply pressure goes behind the piston and remains there. With Toyota’s flex control, apply pressure is controlled by regulating the flow rate of this pressure going in and out of the converter, making this a three-port design (figures 4-6).

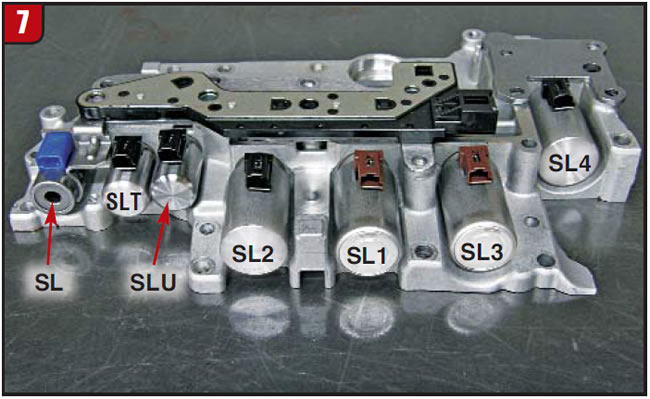

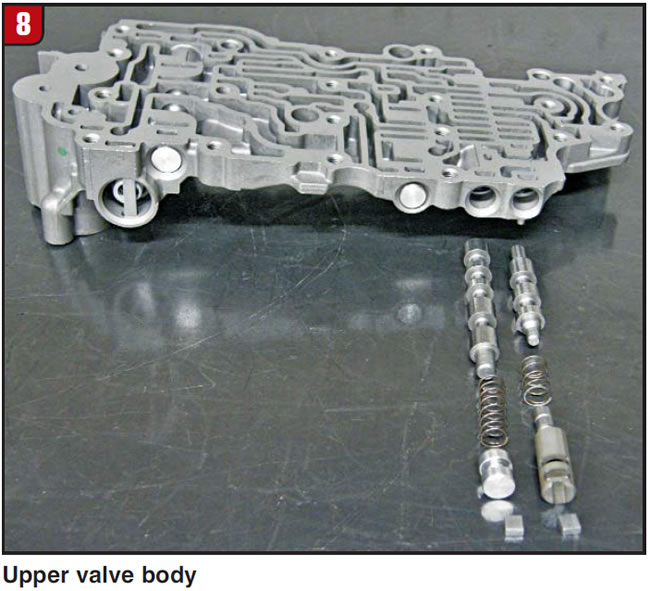

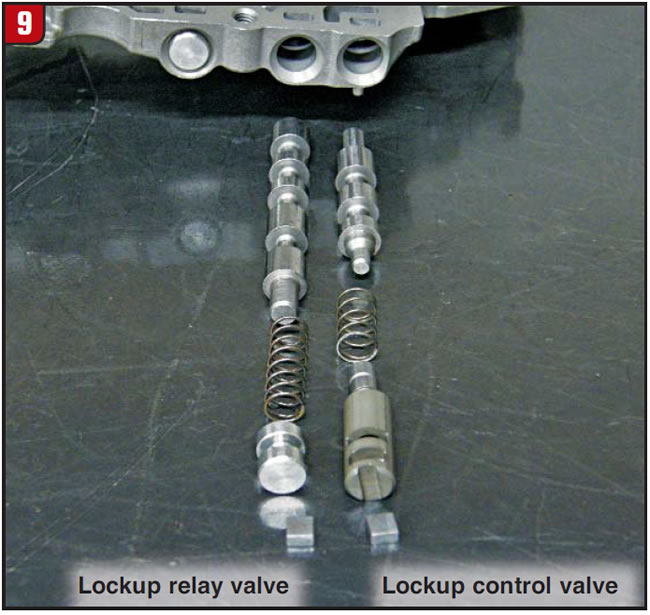

This flex lockup control is accomplished using two solenoids and two valves: the SL and SLU solenoids (Figure 7) and the lockup-relay and lockup-control valves (figures 8 & 9).

The SL solenoid is an on/off solenoid stroking the lockup relay valve. The SLU solenoid regulates the lockup control valve, controlling the flow rate of the clutch-apply pressure while simultaneously controlling the exhaust rate of the release pressure.

Aside from Ford’s CD4E and AX4S three-port non-clutch-pack converters, this three-port system is unique to Toyota. However, you may have noticed that these two lockup valves are made of steel. Chances are we can expect to see valve-body-bore wear with the lockup control valve, since this valve is quite active – something not unique to Toyota or many other manufacturers! So if a U660E comes into your shop with an SL-solenoid performance code P0741 or the SLU P2757, don’t forget to check the bore for wear when inspecting these solenoids and valve lineups.

One other area to stay mindful of is wear with the stator bushing. Toyota has had a history of bushing failure in this area, especially with its a-series front-wheel-drive transmissions, which produced code P0770 for a converter-clutch slip. The bushing in this stator separates the two ports used to control the flex apply. It will be interesting to see what the converter-clutch apply will feel like should this bushing fail.