Up to Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Manual transmission

- Unit: TR3160

- Topic: Design and operation

- Vehicle Application: 2013 Cadillac ATS

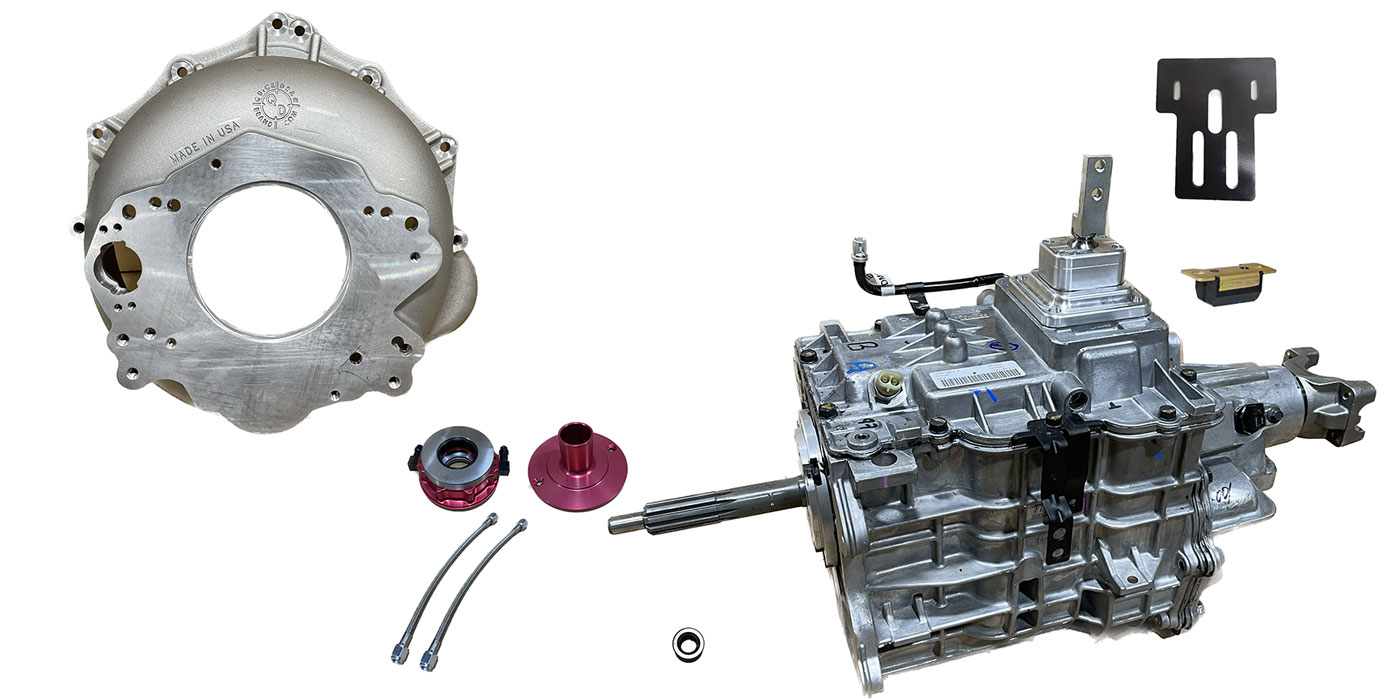

In the never-ending competition between automakers for increased sales, there is an endless supply of new models equipped with newly designed components. Cadillac has produced the new ATS model, which is described as a “luxury compact sports sedan.” The ATS early on became the darling of the motor press and received “2013 Car of the Year” and other awards.

There are several engine options, including a 272-horsepower 2.0-liter equipped with a turbocharger. This is used in a rear-wheel-drive car, and Cadillac turned to Tremec to produce a new six-speed transmission for the 2013 ATS. Labeled the TR3160, the transmission has six forward speeds and can handle 300 lb.-ft. of torque. GM’s RPO code for the unit is M3L. GM believes that it has to offer a manually shifted transmission as an option for a “luxury compact sports sedan” to entice buyers away from competitive brands that offer manual transmissions in other than “muscle cars.”

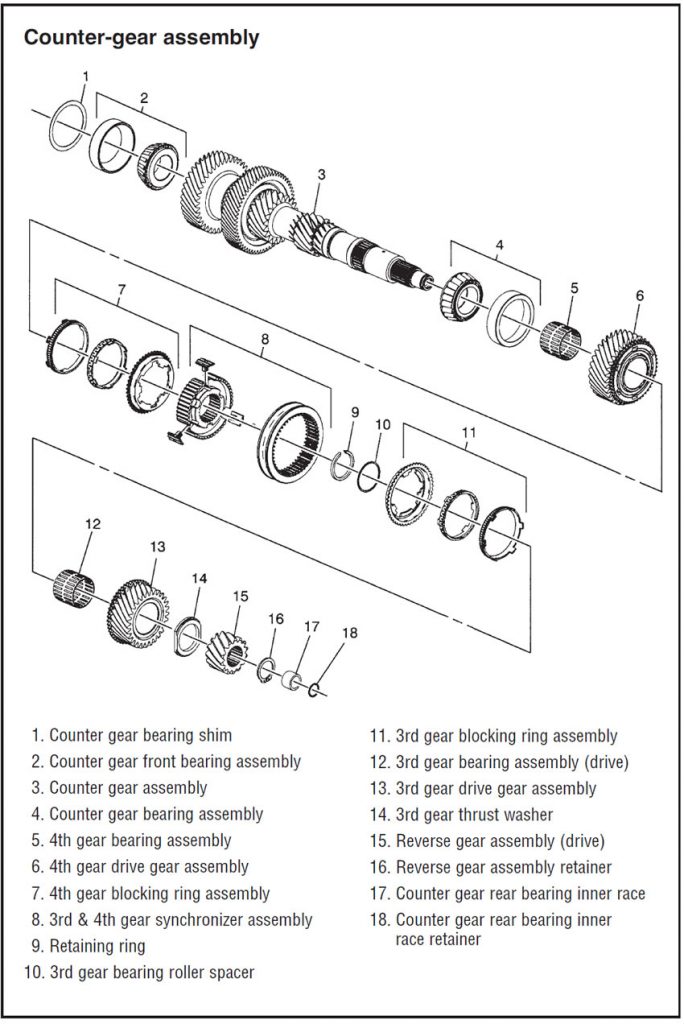

Torque capacity in a manual transmission is based on the centerline distance between the input shaft and the countershaft. The greater this distance the higher the available torque load, as this allows the use of larger gears. The T5 and T45 five-speeds were replaced by the 3650, which has an 85-millimeter centerline distance that increased torque capacity significantly. The TR3160 has an 81mm centerline distance with a torque capacity of 300 lb.-ft. and, used in the ATS, is excellent for a vehicle that is designed with many components made of aluminum and other lightweight materials to improve fuel economy and handling and reduce vehicle weight.

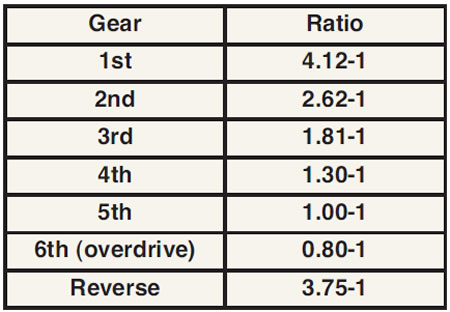

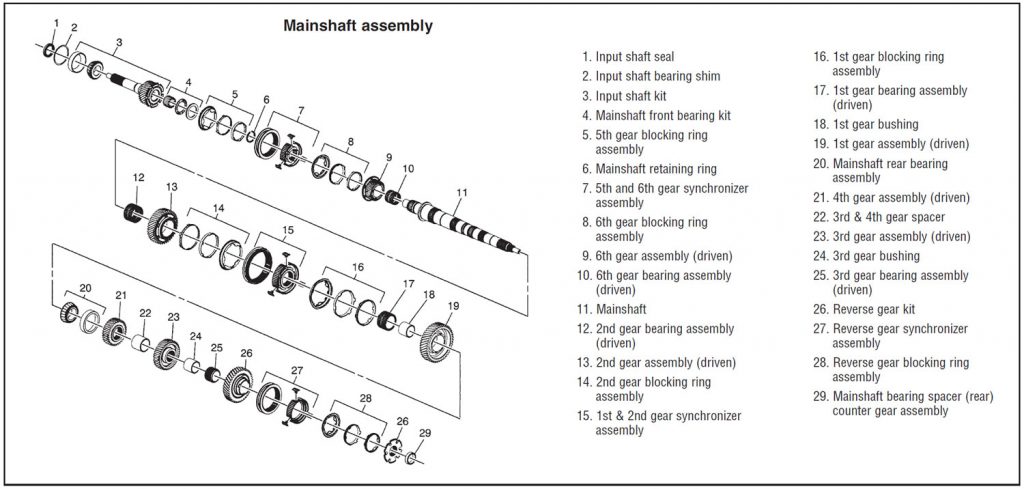

The TR3160 is a six-speed, with a difference from previous American six-speed units in that it has a single overdrive with ratios configured to match European-designed units. In the TR 3160 for the Cadillac ATS, fifth speed is direct drive, similar to the Getrag and ZF units we have become used to. It is possible in future applications for the ratios to be configured to a double overdrive with fourth being direct drive, but in the ATS we have fifth as direct drive, which is an important point to understand when diagnosing one of these units. Because of this layout first gear is next to reverse.

Ratios for the ATS are:

Synchronizer assemblies are the same size as in the TR6060 six-speed found in most of the U.S. muscle cars, giving the synchronizer more torque capacity and resulting in very smooth shifts for a smaller, lightweight vehicle. First and second gears use a triple-cone arrangement; all the other gears, including reverse, use a double-cone ring system. The rings are a “hybrid” design as found in the new TR6070 seven-speed we wrote about last month. One side of the ring uses sintered bronze and the other side uses carbon friction material. The intent here is to provide silky smooth shifts while limiting the wear gap found in the carbon friction material due to its compressibility.

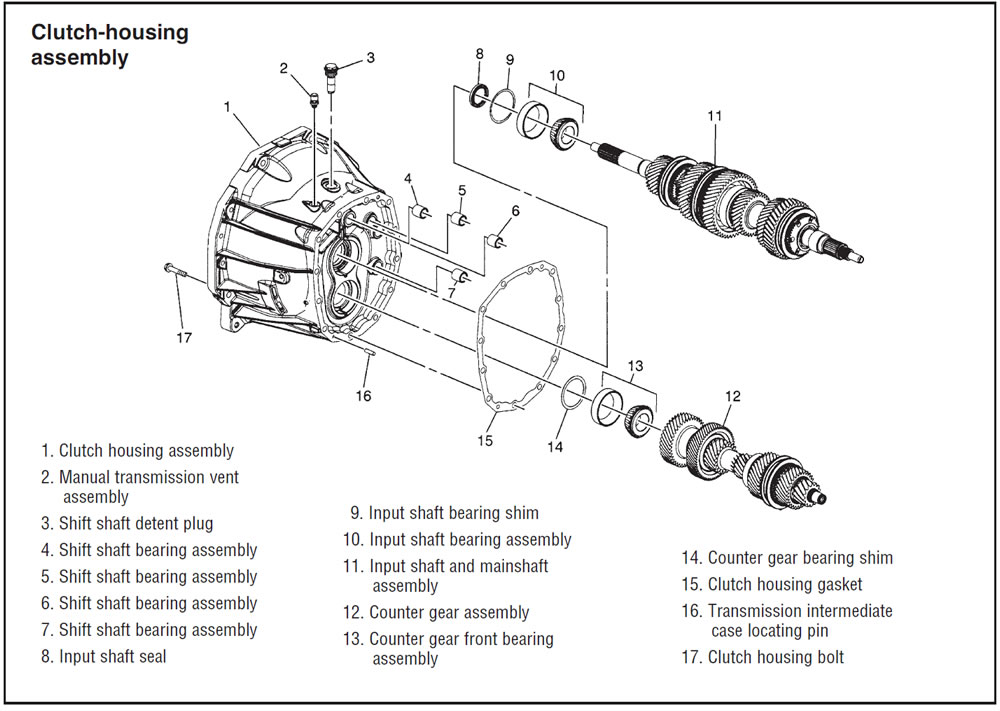

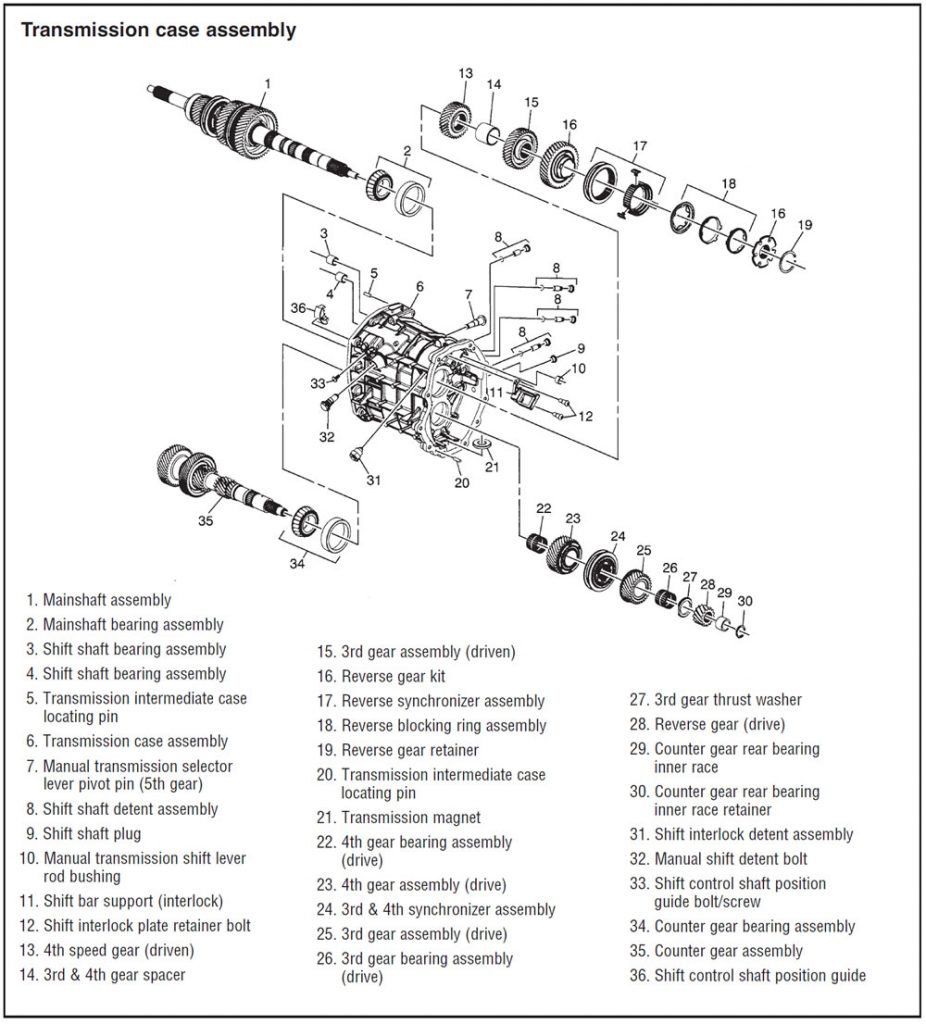

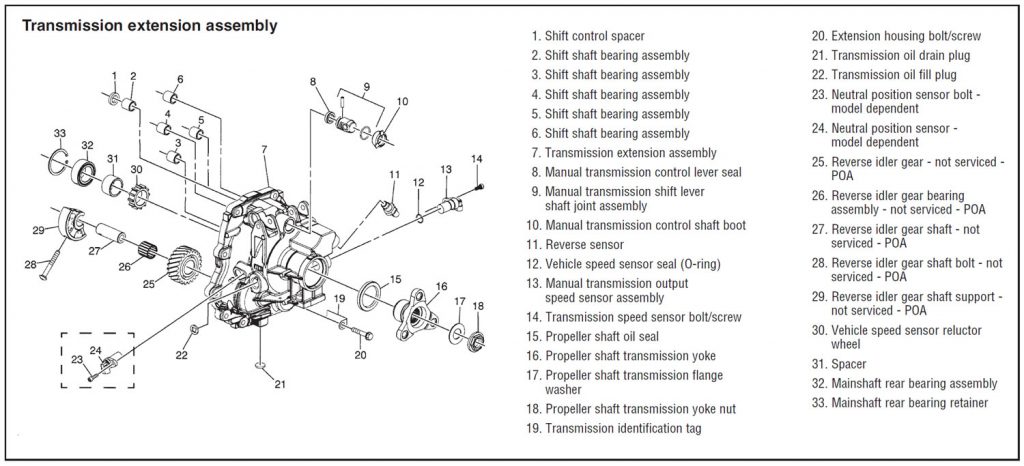

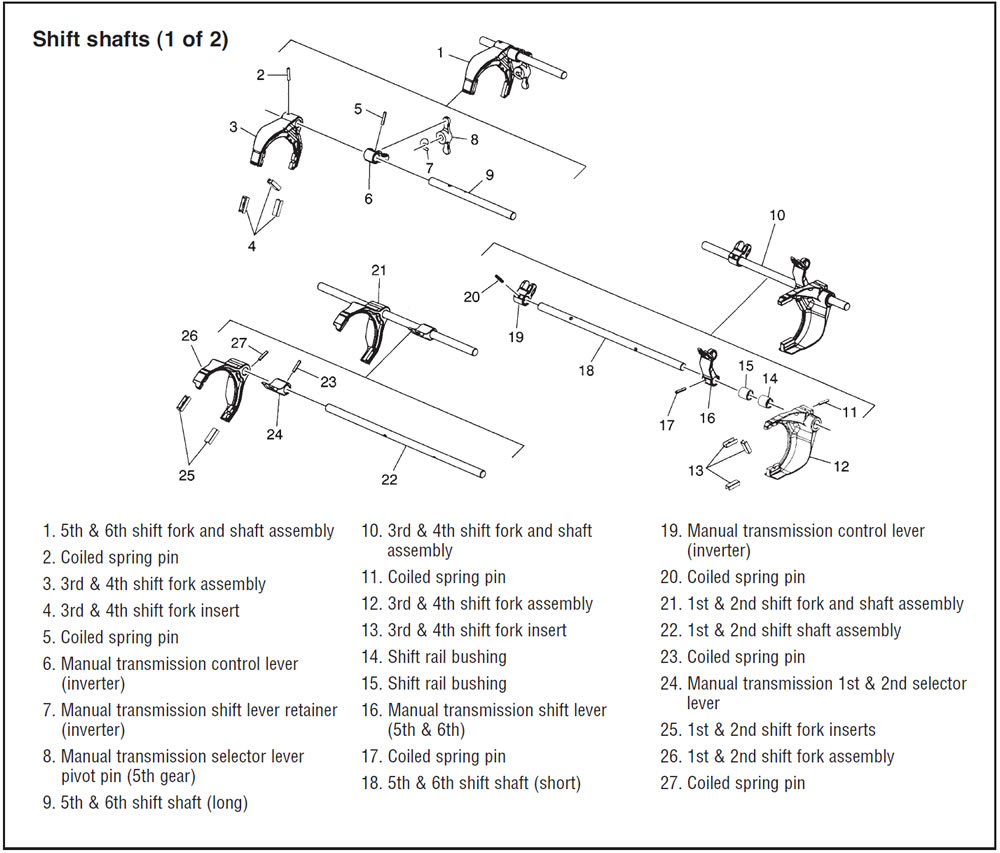

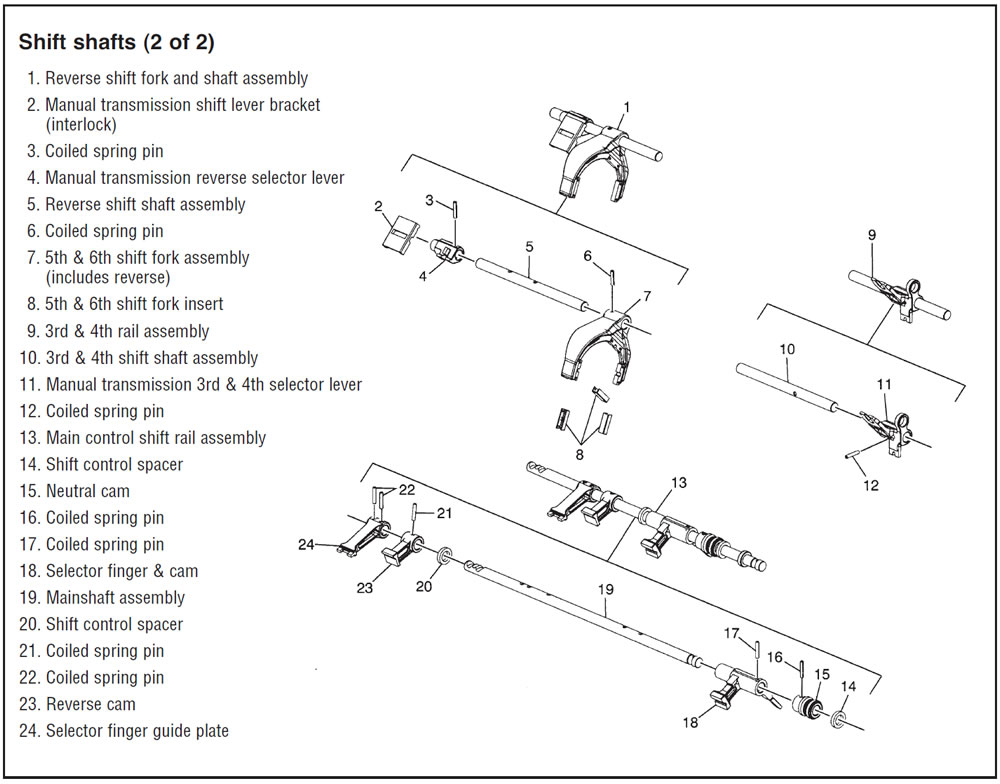

The TR3160 uses an integral bellhousing. The components have been lightened to reduce parasitic drag as much as possible through the gear train to improve fuel efficiency and smooth out the shifts further. This unit weighs 111 pounds dry and is splash lubricated, with no internal pressurized lube and no external cooler function from the factory. Tremec paid a lot of attention to the multiple-shift-rail system to make the shifts smooth. The engineers have improved and massaged the rails and detent notches, as well as the detent system. The detent “bullets” have been engineered specifically for a world-class shift feel with detent springs engineered to match. The bushings and bearings on the shift rails have also been designed for the smoothest operation possible. The TR3160 uses ATF as a specified lubricant to improve cold shifts and provide the right coefficient of friction for proper synchronizer operation. The lube fill is 3.65 quarts of Dexron VI.

The TR3160 uses a reverse-inhibit system to prevent unintended shifts to reverse while the vehicle is in forward motion. This is regulated by the powertrain control module (PCM) and a transmission-mounted reverse-inhibit solenoid. When the ignition is in the run position, there is battery voltage directly to the solenoid. If the vehicle is in forward speeds above 3 mph, the PCM de-energizes the reverse-inhibit solenoid, which mechanically blocks the shift lever from making a shift to reverse.

It is a pleasant surprise to see a manual-transmission option in a new vehicle model, as the stick transmission has been declining as an option on most American car and truck production. The TR3160 is well designed for the intended use and will become a “family” of units with different ratios for future models.

Although it is not a difficult unit to work on, there are several points that need to be addressed on disassembly. It is always proper work method to match-mark the synchronizer assemblies before removing them from the associated shaft. By doing so you will also capture the wear pattern of the sliding sleeve to the synchro hub so as not to change shift feel, and you will always know which direction the synchro assembly faced originally.

You also should pay attention to marking the top side of the snap rings that retain the components on the shaft. Snap rings are cut on an angle at the opening, and the point of the angle should always be up so that the snap-ring pliers have something to grab onto during removal and assembly.

The more things change, the more they remain the same.

Mike Weinberg is president of Rockland Standard Gear.