Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Cadillac CTS, no engagement

- Issues: Transmission output shaft, transfer case

Complaint/Concern:

The owner of a 2010 Cadillac CTS started to notice a clicking sound when placing the transmission into drive or reverse. Due to a busy schedule, the owner chose to delay bringing the vehicle in for an inspection, until one morning that the transmission failed to make any noise. The noise was gone, replaced by a no-movement condition that brought the busy schedule to a screeching halt.

Having a dead car to deal with, the customer had no choice but to contact the shop and make arrangements to have the vehicle towed in. Once the vehicle showed up, the inspection process began to determine what the problem was.

The CTS was equipped with a 3.6L engine and 6L50 six-speed automatic transmission. The vehicle was AWD, which meant dealing with more than just a potentially bad transmission. With the engine running, the transmission was placed into drive and reverse, but, as a customer indicated, there was no engagement. The engine ran well and there were no check engine lights or related trouble codes. The vehicle only had 71,000 miles on it and there were no issues up to that point.

Something odd did occur when the shifter was placed into drive, and that was the speedometer started to register, and when the shifter was placed back into park a raking noise occurred, indicating that the output shaft was turning and the problem most likely was in the transfer case.

Cause/Condition:

The vehicle was put on a lift to see if anything was falling apart; however, everything appeared to be intact. With the engine running and the vehicle up in the air, the noise could clearly be heard at the back of the transmission. The question became, was the problem with the transmission output shaft or with the transfer case? The transfer case was removed and the problem was spotted immediately. Not only were the splines of the transfer case input shaft stripped, the splines on the output shaft of the transmission were not in great shape either, so out came the transmission.

Correction/Modification:

Over the years, there have been instances of transmission output shaft splines being stripped off, affecting the transfer case input shaft or gear; however, that scenario has been somewhat limited. The failure on the CTS must be a bit more common, since GM had issued a TSB concerning the problem under bulletin number 10-07-30-005A. A contributing factor to the shaft spline wear is lack of lubrication between the transmission and transfer case. Unlike other 4WD applications that use a pressurized or splash-lube system, the CTS basically runs dry, which can result in premature spline wear.

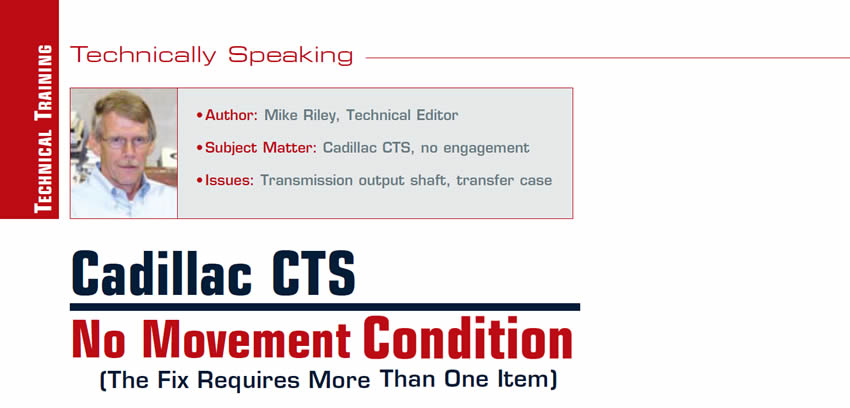

To address this issue, GM has modified the transmission output shaft at the splined area (Figure 1). First-design output shafts merely have splines cut into the end of the shaft, whereas the upgraded replacement output shaft utilizes shorter splines providing an area that an O-ring groove can be cut into.

The situation concerning wear between the transmission output shaft and transfer case input shaft extends beyond 2008-10 CTS models. Other models such as the 2007-10 STS and 2007-09 SRX are afflicted with this problem as well and will require the same type of repair.

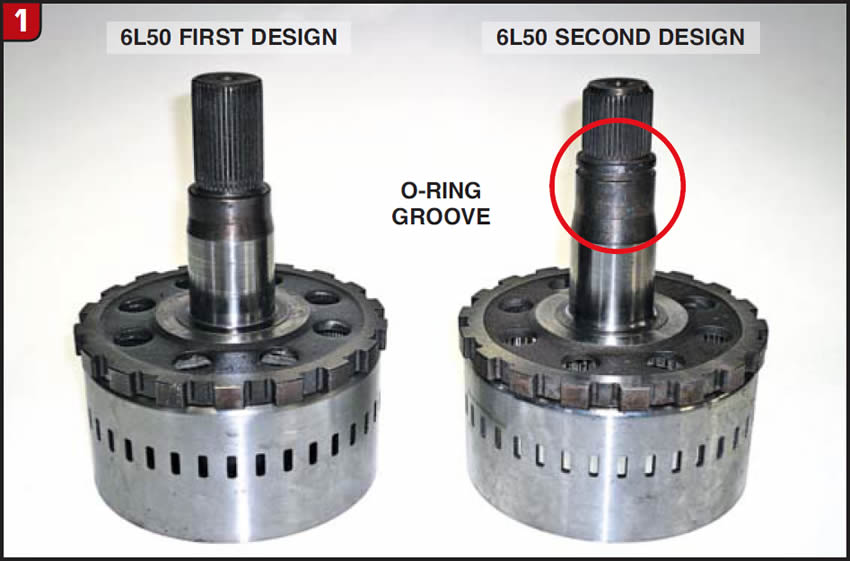

Cadillac CTS models can be equipped with more than one engine size or transmission type. Other CTS models could have a 3.0L engine and a 6L45 transmission, which will change the outcome slightly. Although the 6L45 and 6L50 transmission models are the runts of the RWD six-speed transmission family, there are a couple of differences between them, one of which being the output shaft (Figure 2). The reason that the 6L45 shaft is shorter than the 6L50 is that the 6L45 only uses one ring gear whereas the 6L50 has two, just like big brothers 6L80/6L90. Planetary design between the two models is also different. Before ordering the replacement shaft, check for the RPO code; MYA – 6L45, MYB – 6L50.

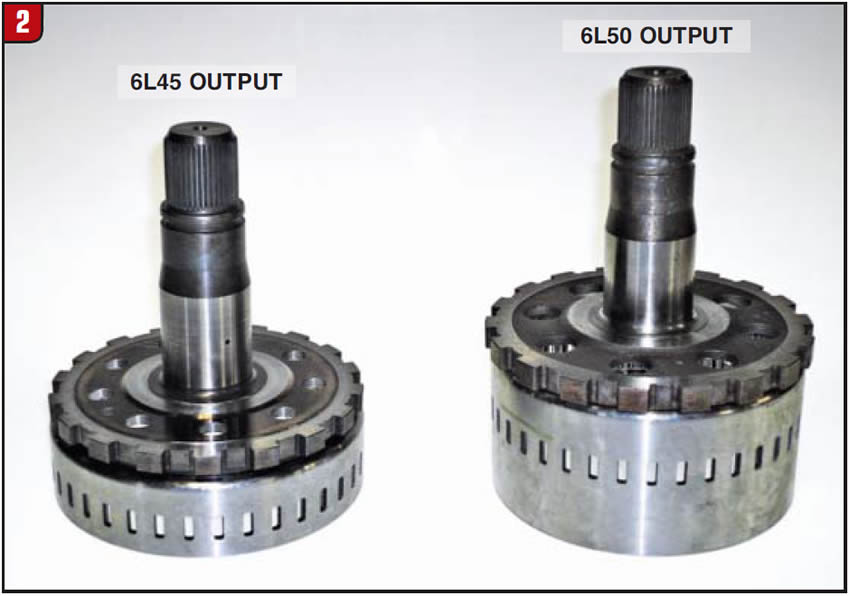

Unfortunately, the transmission output shaft is just one half of the equation, with the transfer case input shaft being the other half. When GM modified the output shaft to accept an O-ring, the bore of the transfer case input shaft had to be modified as well and of course there is not one fits all. The transfer case type is dependent upon vehicle model, each requiring a different input shaft (Figure 3).

CTS vehicles use a Borg Warner transfer case model 4477, which has a clutch-pack assembly similar to an automatic transmission, although it is applied by electrical means. STS and SRX vehicles use a Borg Warner transfer case model 4479, which has a planetary gear set and is a bit more robust. As with the transmission output shaft, make sure to order the correct transfer-case input shaft depending on model.

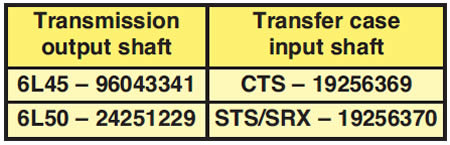

Regardless of the transfer case model, the input shaft is modified in the same manner, (Figure 4). The leading edge of the bore is smooth to accept the O-ring that was added to the transmission output shaft. Previous input shafts have splines that extend to the end of the shaft bore, which is why an upgraded transmission output shaft cannot be used with the previous design transfer-case input shaft. Due to either interference or the inability to retain a lubricant, matching both shafts is critical.

During reassembly use a good high-temp wheel-bearing grease on the output shaft splines.

Component part numbers are as follows:

Overall, the transmission and transfer case were in good shape, requiring only the two shafts, so the units were reassembled with minimal components. The transfer case gasket is part number 24231525. Once done, the vehicle was driven and worked well. The customer was finally able to resume his busy schedule and learned a valuable lesson to boot.