Up to Standards

- Subject: Design and operation

- Unit: NVG 146

- Vehicle Application: Grand Cherokee SRT8

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

If you live long enough you will eventually see it all. Chrysler Corp., which manufactures the Jeep brand of vehicles, has brought to market a Jeep “muscle car.” Introduced in 2006, the Grand Cherokee SRT8 model was designed to give Jeep an on-road performance vehicle. For as long as the Jeep line has been produced under different corporate ownership, Jeeps have been known as off-road-capable vehicles, used at first by the military and then by the public after WWII. Now the market planners at Jeep have created a street-driven performance SUV in the Grand Cherokee SRT8 models.

SRT8 stands for “Street and Racing Technology,” which is the performance group of Chrysler Corp, and the 8 signifies a V-8 engine. The SRT people put a whole lot of oomph into this vehicle, designed to compete with the BMW X5 and X6 models and comparable Mercedes-Benz SUVs. Powered by a 6.1-liter Hemi engine, the Grand Cherokee SRT8 is the second-fastest vehicle in the Chrysler line, surpassed by only the Dodge Viper with its V-10 power plant.

The performance group lightened the vehicle and reduced the ground clearance to 7 inches, which makes off-road use out of the question. The engine produces 425 horsepower and 425 lb.-ft. of torque. The 0-60mph time is 4.6 seconds, with a 13.2-second quarter mile at 104 mph – impressive for a stock full-sized vehicle.

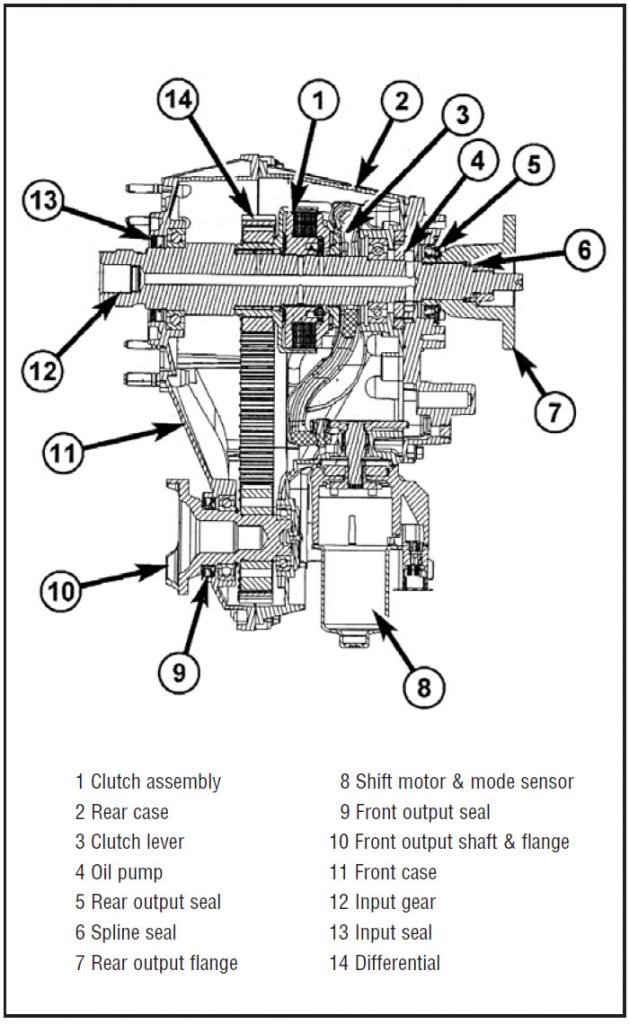

The SRT engineers added gas-charged Bilstein shocks, a road-race suspension and Brembo brakes, resulting in a vehicle that can pull 0.92 g on the skid pad. The design is interesting from our perspective in that it uses an open-differential Dana 44 on the rear and an open differential for the front axle, with the transfer case doing all the work of biasing the torque load to the front and rear axles. The transmission is the Mercedes WA850, known in Chrysler speak as the 545RFE, coupled to an NVG 146 transfer case. The 2011 model is slated to have a 6.4-liter Hemi engine, which should further boost these amazing elapsed-time specs.

One of the most-unusual aspects of this model is that the tire sizes are different between front and rear. The fronts are 10 inches (255mm) wide and the rears are 11.2 inches (285mm) wide, with both front and rears the same tire circumference. It should be obvious by now that tire sizes and pressures play a major role in creating transfer-case and differential diagnostic problems, so it is critical here to make sure that all tire circumferences are within 1/4 inch of each other.

The NVG 146 is an all-wheel-drive system. This means that the driver has no control over transfer-case engagement and there is no shift control, as this unit has only high range with no low range available. The torque-bias capability between the front and rear axles is on demand through the computer-controlled system. The transfer case is capable of sending between 0 and 50% of torque to the front axle whenever the electronics determine there is wheel slip. The Brake Traction Control System (BTCS) works in conjunction with the on-demand four-wheel-drive program to apply braking to any wheel that is slipping while the transfer case sends torque to the wheels that have traction. This means that the antilock-braking system is an active component in this design, so that the driver will be able to stay on his intended path even though he has exceeded the throttle position or steering angle for the turn.

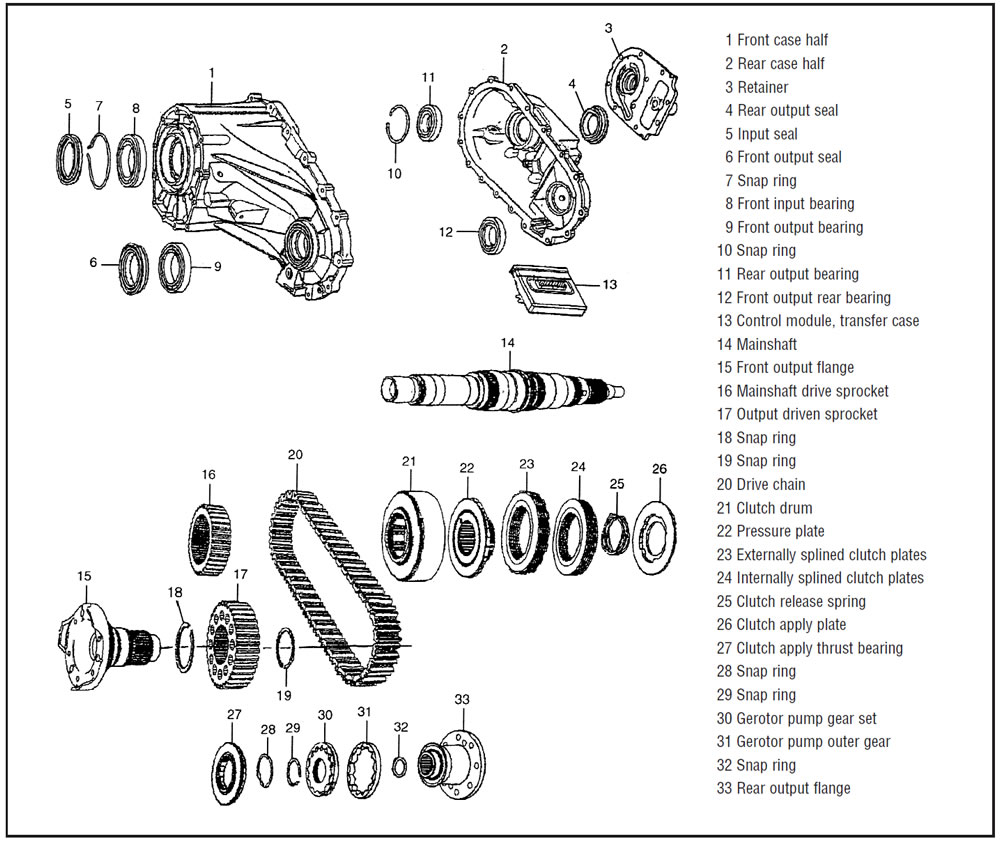

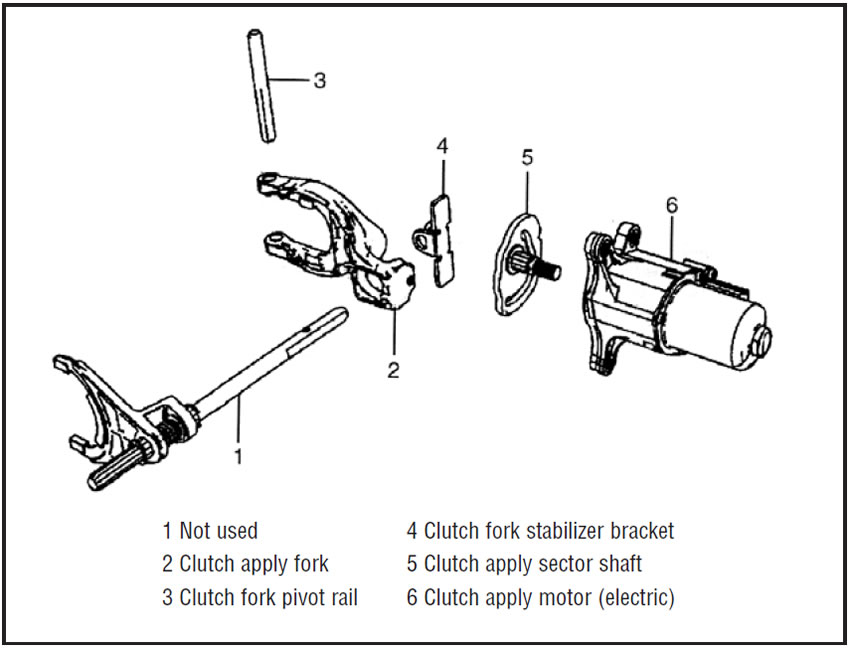

The NVG 146 uses an internal wet-clutch pack to bias the torque. The final-drive control module (FDCM) constantly checks all four wheels’ speeds to detect a slip. Inside the FDCM computer program is a vehicle-dynamics model that knows how much torque and how much brake to apply to stop wheel spin under any driving condition. An electric motor on the transfer case engages the sector shaft to apply the multiple-disc wet-clutch pack from 0 to 100% duty cycle. Since the clutch plates are alternately splined to the front and rear output shafts, the front and rear axles’ speeds can be equalized.

The internal clutch pack is engaged through the sector shaft turning to apply an internal clutch fork, which applies the clutch-pack pressure plate in a similar fashion to the NVG 226 and 246 models that have been around forever. This unit is pressure lubricated by an internal gerotor pump driven by the output shaft. Lube quality is another critical issue, as the correct lube and the quality of the lube directly affect clutch-pack operation. Burnt fluid or low fluid levels in this transfer case can be the cause of many drivability complaints and create DTCs that make diagnostics more of a challenge if you disregard the fluid and tire sizes before beginning your diagnostic routine.

This system can set 27 “C” codes and 5 “U” codes, with the communication from the FDCM traveling through the CAN C bus. There are twice as many pages in the repair manual for electronic diagnosis as there are for mechanical repair, so we will cover the electronics in the August issue.

This is a simple transfer case with only 4W High capabilities. There is no low-range planet and no shift forks. The components are beefy to handle the 425-lb.-ft. torque load and are priced accordingly. This model is definitely a performance vehicle, and regardless of whether it makes sense in this economic climate, it is selling. The good news is that the people who buy these kinds of cars really try them out, and eventually they will make their way into the repair shop.