Up to Standards

- Author: Mike Weinberg, Contributing Editor

You Can’t Tell the Players Without a Scorecard

Over the past 10 years, I have written numerous articles for this magazine regarding transfer cases. The transfer case, which is simply a power divider that allows torque from the transmission to be split between the front and rear axles to provide four-wheel drive, has become very sophisticated and, therefore, more complex.

In the manual-transmission market, stick-shift transmissions make up roughly 20% of the vehicle population, with automatic transmissions grabbing the lion’s share of the market. The transfer-case market has exploded with the variety of SUVs and crossover vehicles being added to the market and the fact that whether the transmission is manual or automatic, a transfer case must be involved to obtain four-wheel drive.

As the market evolved from work-type vehicles to more-expensive and luxury-oriented vehicles that the soccer moms are buying, the transfer case has been refined to make it easier for the driver to operate. Whereas once the driver had to exit the vehicle to engage the locking front-axle hubs and then shift the transfer case manually to provide a 50/50 torque split to both axles, we now have electronically shifted transfer cases that operate with dashboard or console switches, or “on demand” four-wheel-drive systems that operate without any input from the driver as an ECM (computer or electronic control module) senses wheel slippage and sends power to the axle that needs it.

Now we factor in other systems designed into the modern vehicle to provide added safety and handling such as antilock braking, stability control and traction control and we have very complex electronically controlled systems that are interrelated. On our technical hotline, transfer-case problems account for 75% of all customer help-line calls.

New Venture Gear started life as a joint venture between the New Process Gear division of Chrysler Corp. and the Muncie Transmission division of General Motors. After about 10 years, this joint venture has been dissolved, with DaimlerChrysler retaining the New Venture Gear name and the transfer-case manufacturing business.

This article is devoted to understanding the functions and terminology of various New Venture Gear designs and an identification section to help you know which transfer cases you will find in the various late-model vehicles that use the product.

New Venture Gear defines four-wheel drive as a system to transfer power to all four wheels for enhanced vehicle performance. It further defines enhanced vehicle performance as improved traction for both on- and off-road conditions, improved vehicle handling and improved safety.

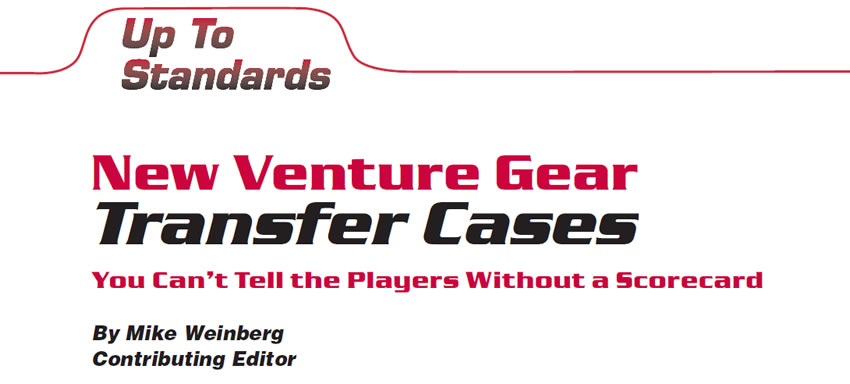

The improved-traction part is easy enough to understand, as it is obvious that four driving wheels will perform better than two in low-traction conditions such as snow, ice, mud, sand or off-road travel. The safety and handling parts of the equation require us to have an understanding of basic vehicle dynamics. The two vehicle characteristics that come into play here are understeer and oversteer.

Understeer (or in racing speak, push) means that when you turn into a curve the wheels are turned but the vehicle wants to continue in a straight line and drives through the front tires to some degree. Easing off the throttle permits the front tires to bite and the car turns in.

Oversteer (or “loose”) is when the front wheels are turned into the corner and the rear wheels want to pass the front wheels on the outside of the turn, in effect causing the car to spin. All modern vehicles are designed with some slight understeer built in, as it is the safest thing for the average driver.

The chart included here gives you an idea of the effects of various four-wheel-drive systems on vehicle performance through a constant-radius turn. As you can see, part-time four-wheel-drive systems and front-wheel-drive designs tend to have the most understeer. Full-time four-wheel drive has less understeer and helps the vehicle to get closer to the desired path of travel, on-demand four-wheel drive comes closest to the correct line, and rear-wheel drive has the greatest tendency to oversteer.

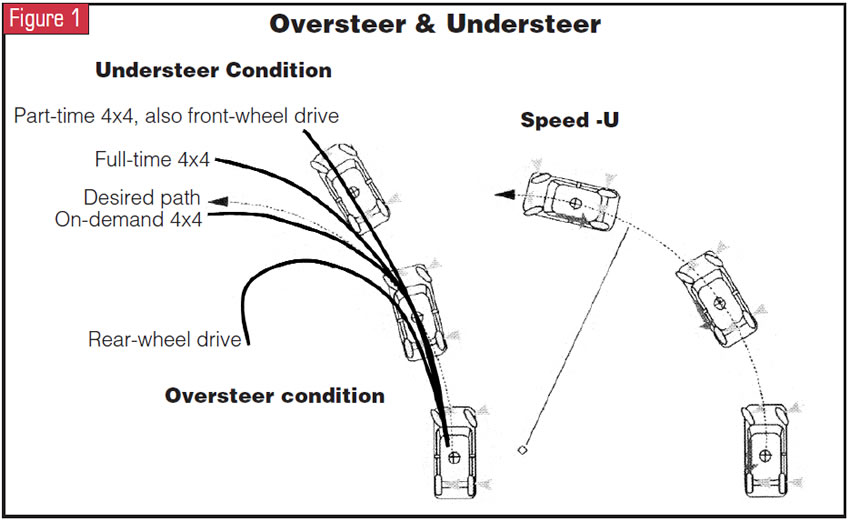

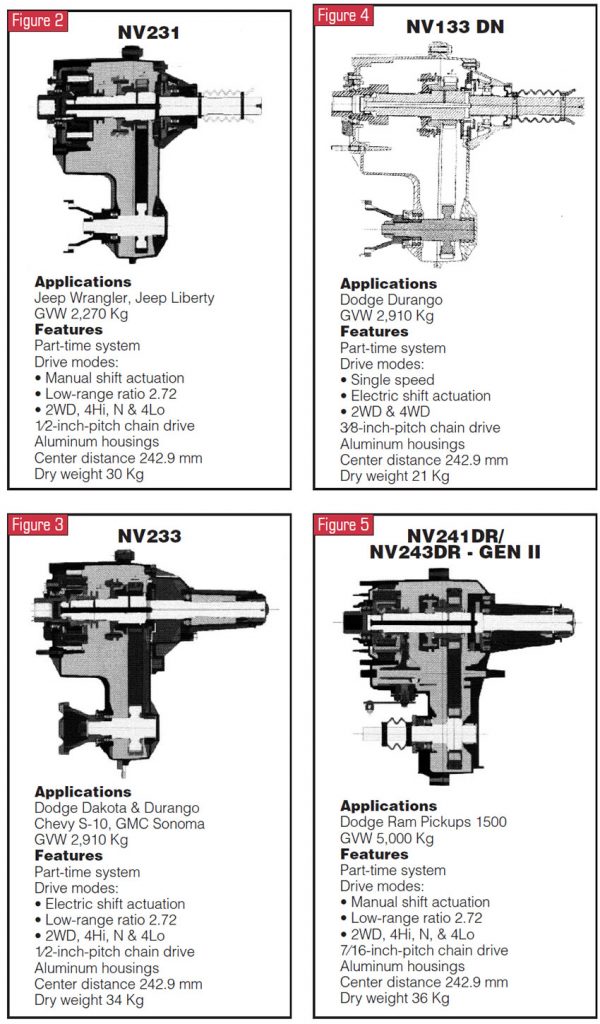

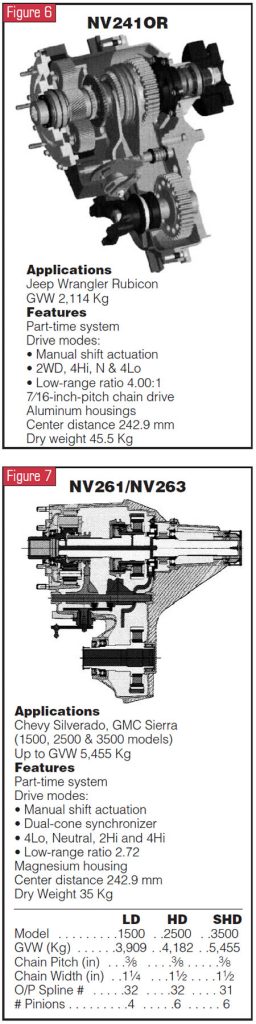

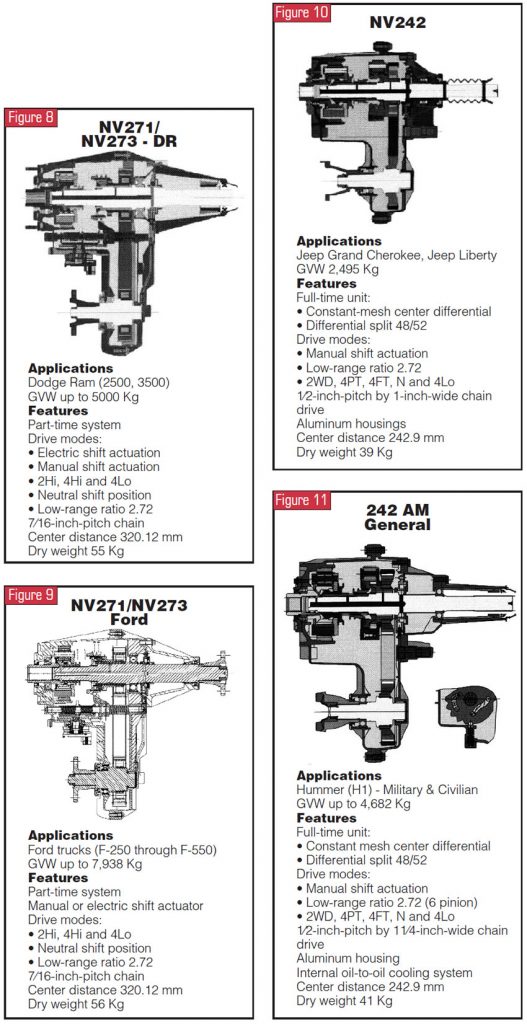

Part-time 4WD systems have the vehicle normally in the two-wheel drive-mode, with the driver selecting 4WD when it’s desired. These systems generally are lightweight and offer the best traction with 4WD engaged. The disadvantages of the part-time systems are that they require a higher skill level from the driver, as they affect vehicle handling dramatically, and they tend to have a lot of tire scrub and wheel hop, particularly on blacktop.

New Venture Gear late-model units that are part time 4WD are the NV231, NV233, NV133DN, NV241DR, NV243DR, NV241OR, NV261LD, HD, SHD, NV263LD, HD, SHD, NV271DR, NV273DR, NV271 Ford and NV273 Ford.

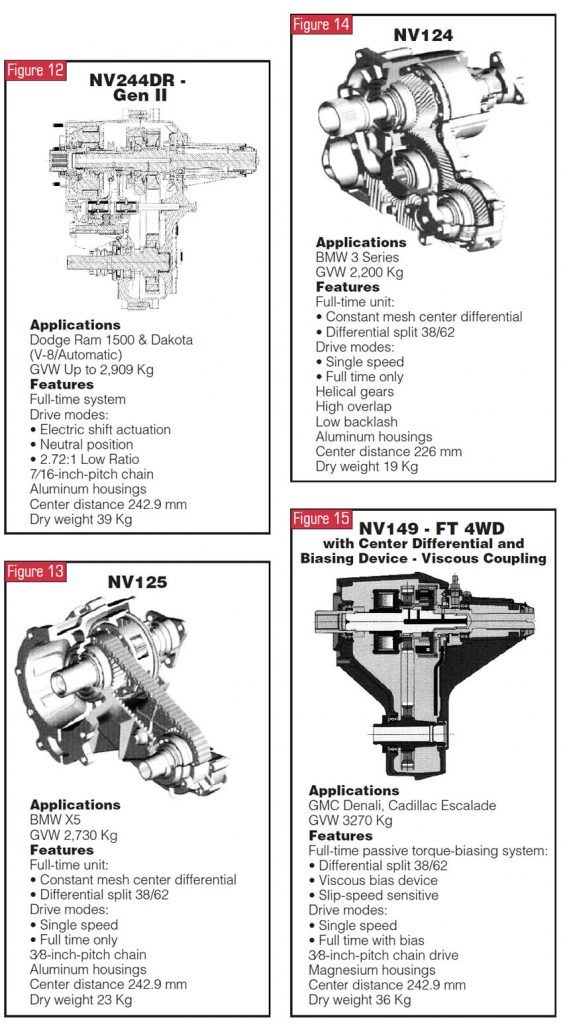

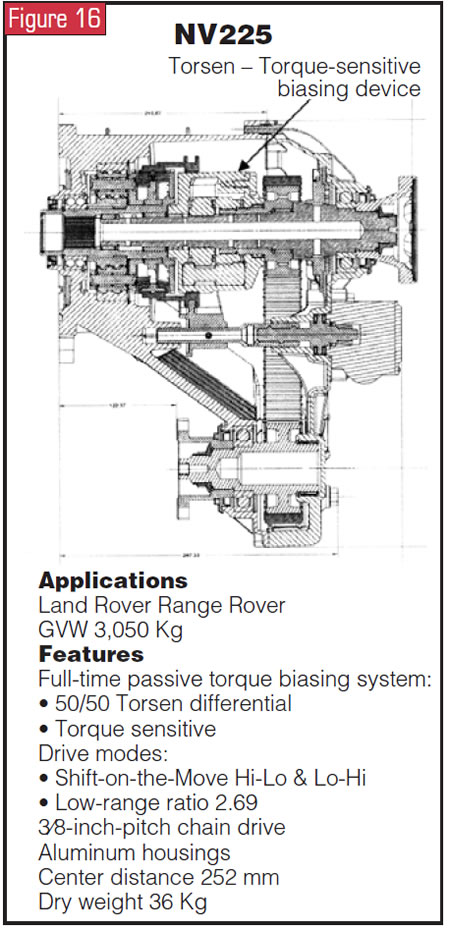

Full-time 4WD systems have the power going to all four wheels of the vehicle under normal operation. These systems feature some type of open-center differential and varying torque splits (in percentage, front axle to rear) including 48/52, 47/53 and 38/62. These units also can be designed with torque-biasing devices such as clutch packs or viscous couplings. The advantages of this type of design are no tire scrub or wheel hop on turns, improvement in vehicle handling and better traction. These systems are limited by open-differential slippage and the reactive nature of the design. There is some built-in lag time before the system reacts to changing conditions.

Late-model New Venture Gear full-time transfer cases include NV242, NV242 AM General, NV244DR Gen II, NV125 and NV124.

Full-time 4WD with center differential and viscous coupling is found in the NV149 transfer case. The advantages here are no tire scrub or wheel hop, better traction and handling, and open-differential slippage is overcome through the viscous-coupling biasing system. Disadvantages are that tire size and pressures are extremely influential on coupling performance and longevity, and the system is still reactive.

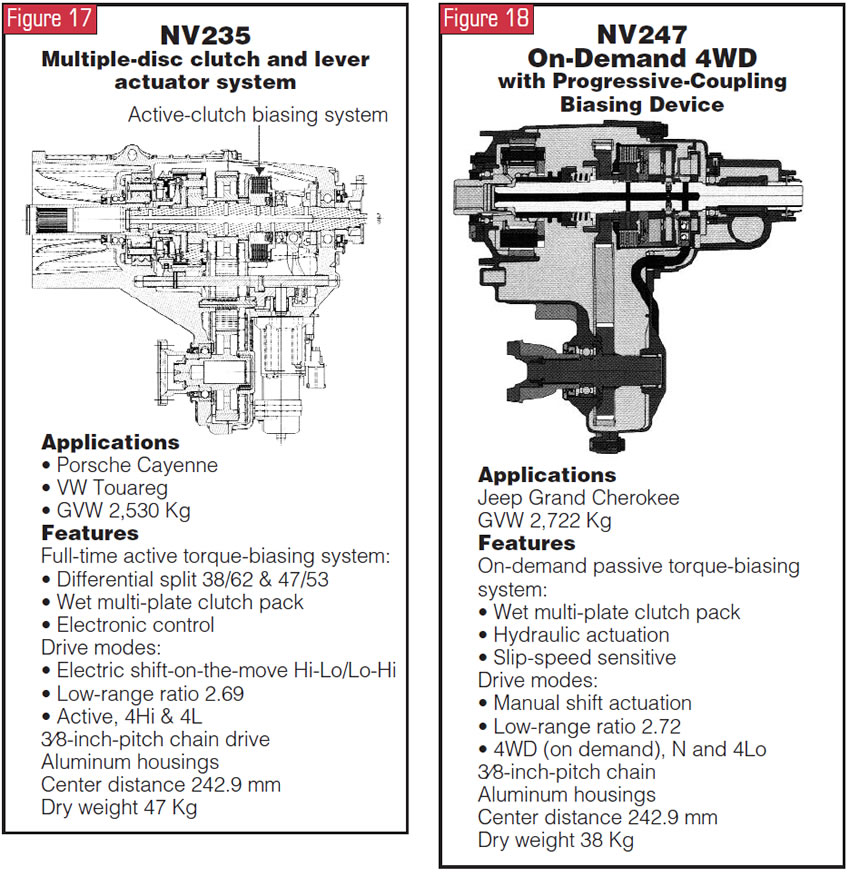

Full-time 4WD with center differential and torque-sensitive Torsen biasing device is found on the NV225 transfer case, which is used in Range Rovers. The advantages are no wheel hop or tire scrub on turns, better handling and traction, operation that is transparent to the driver, and differential slippage controlled by the 50/50 Torsen torque-bias system. This is still a reactive system

Full-time 4WD with center differential and active-clutch-system torque biasing is found in the NV235 transfer case, which is used on the Porsche Cayenne and VW Touareg models. These vehicles have no tire scrub or wheel hop, power to all four wheels all the time, active-clutch bias system to eliminate open-differential slippage, full integration with traction control, optimum handling performance because of electronic interface with vehicle systems, and operation that is transparent to the driver. The disadvantages of this system are weight and price.

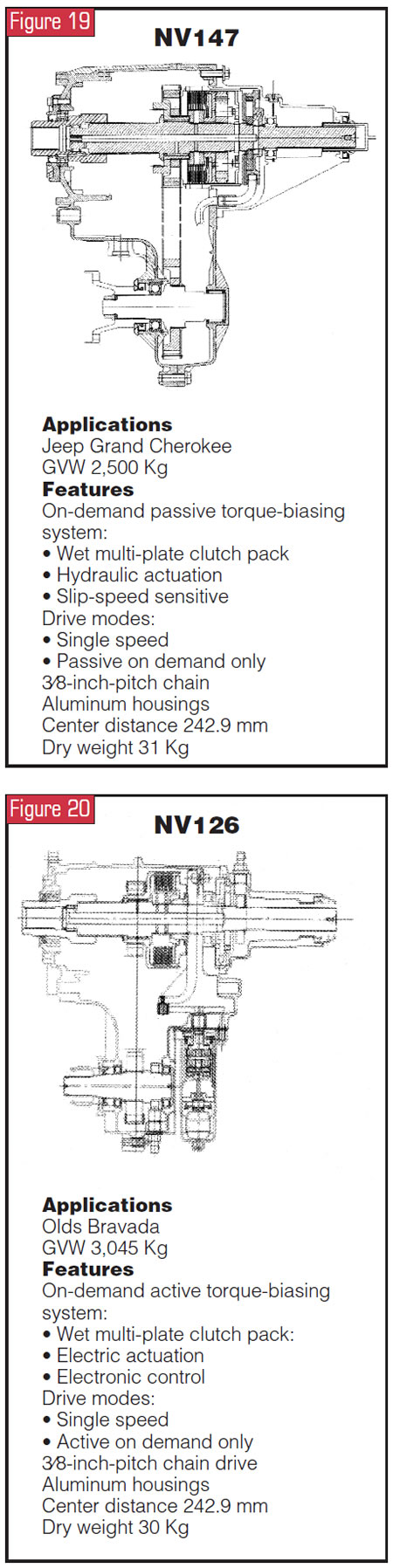

On-demand 4WD has the vehicle operating in 2WD normally, with 4WD activated automatically through a mechanical torque-transfer device when slippage occurs at the driven axle. There are several designs of bias systems. The progressive-coupling bias system has a faster response than viscous couplings and can be cooled for thermal protection. The disadvantages are that the pump coupling and clutch pack are sensitive to type and quality of the lubricant used and can be overheated with extreme use such as snow plowing. These units are designated NV247 and NV147.

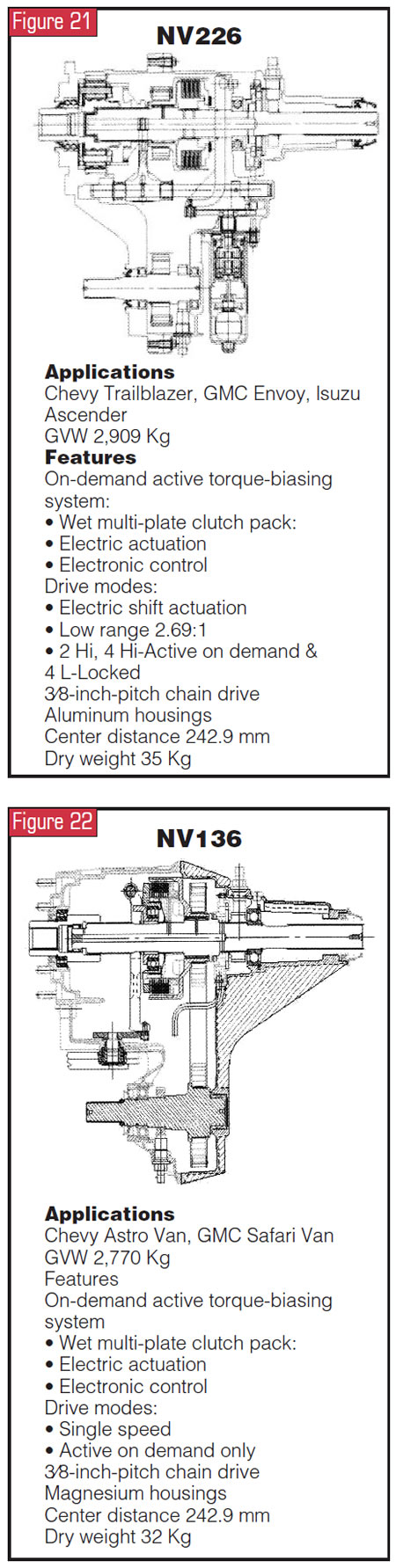

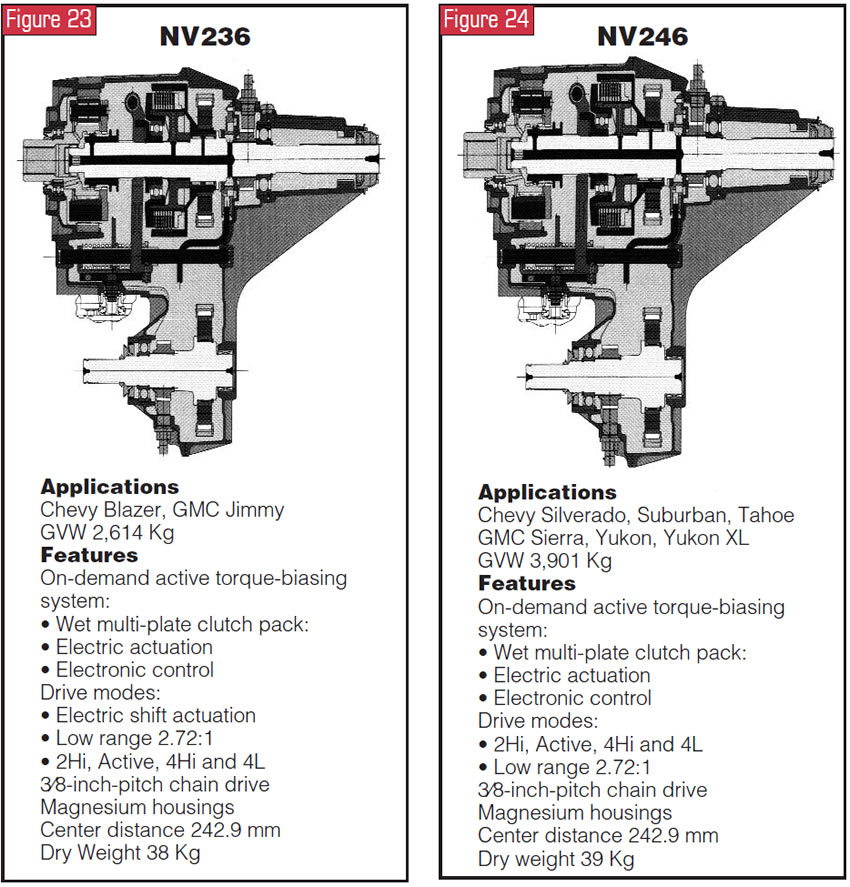

A vehicle with on-demand 4WD with active clutch system for torque bias is normally operated in 2WD mode, with speed sensors monitoring slippage across the axles. 4WD is engaged automatically through an electronic torque-transfer device when slippage occurs at the rear axle. These units use an electronically controlled clutch pack to transfer torque. Traction and directional stability can be adjusted to meet the vehicle performance requirements through a programmable external control logic. The disadvantage of this design is that tire pressures and size are critical. On some systems 1⁄16 inch difference in wear between tires can set a code. The units that have this design are the NV126, NV226, NV136, NV236 and NV246.

We have included illustrations of each model of transfer case with a chart for its features and the vehicle models in which it is used. Obviously, the transfer case is not just a simple power divider any longer, but a complex device that must be integrated into the other design systems of the vehicle. Look at the vehicle as a series of interrelated systems that must function together for proper operation and you will have gone a long way in learning how to diagnose these systems. As I told you, you have to buy the program to know who the players are.