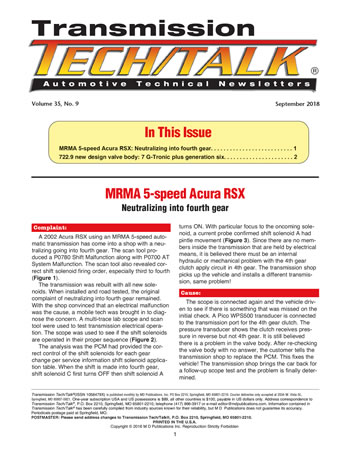

A 2002 Acura RSX using an MRMA 5-speed automatic transmission has come into a shop with a neutralizing going into fourth gear. The scan tool produced a P0780 Shift Malfunction along with P0700 AT System Malfunction. The scan tool also revealed correct shift solenoid firing order, especially third to fourth (Figure 1).

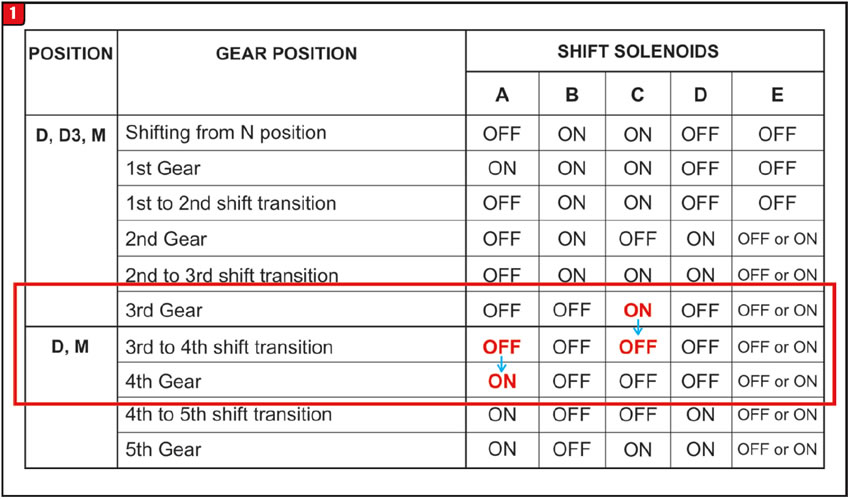

The transmission was rebuilt with all new solenoids. When installed and road tested, the original complaint of neutralizing into fourth gear remained. With the shop convinced that an electrical malfunction was the cause, a mobile tech was brought in to diag-nose the concern. A multi-trace lab scope and scan tool were used to test transmission electrical operation. The scope was used to see if the shift solenoids are operated in their proper sequence (Figure 2).

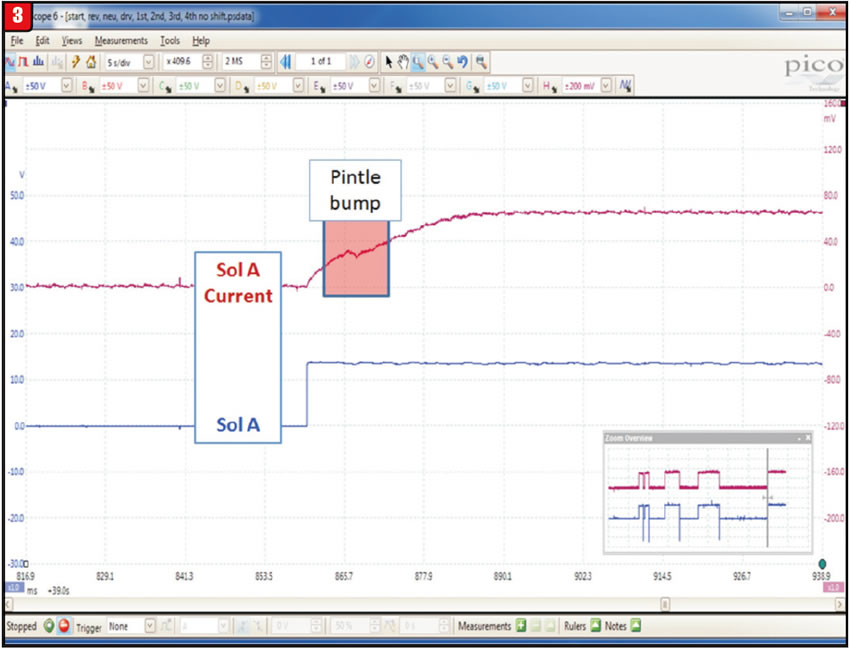

The analysis was the PCM had provided the correct control of the shift solenoids for each gear change per service information shift solenoid application table. When the shift is made into fourth gear, shift solenoid C first turns OFF then shift solenoid A turns ON. With particular focus to the oncoming solenoid, a current probe confirmed shift solenoid A had pintle movement (Figure 3). Since there are no members inside the transmission that are held by electrical means, it is believed there must be an internal hydraulic or mechanical problem with the 4th gear clutch apply circuit in 4th gear. The transmission shop picks up the vehicle and installs a different transmission, same problem!

The scope is connected again and the vehicle driven to see if there is something that was missed on the initial check. A Pico WPS500 transducer is connected to the transmission port for the 4th gear clutch. The pressure transducer shows the clutch receives pressure in reverse but not 4th gear. It is still believed there is a problem in the valve body. After rechecking the valve body with no answer, the customer tells the transmission shop to replace the PCM. This fixes the vehicle! The transmission shop brings the car back for a follow-up scope test and the problem is finally determined.

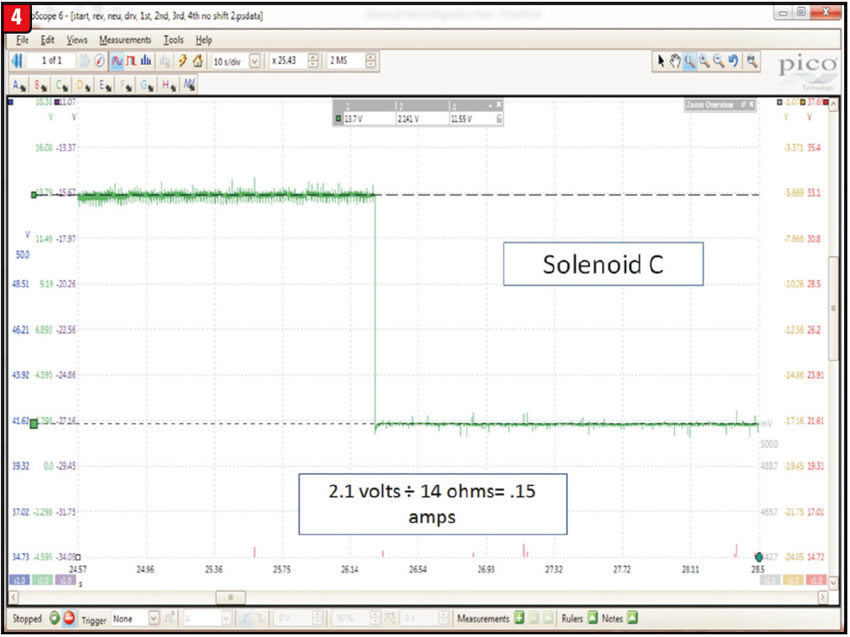

Final analysis: After performing a follow-up scope of the new computer to compare solenoid shift sequences with the original computer, it is discovered that shift solenoid C did not completely turn off (Figure 4). The PCM provides system voltage to the solenoid through the “High Side Driver-HSD” inside the PCM. When this solenoid is fully energized approximately 13.7 volts can be seen. When the HSD shuts off 0 volts should be observed. A closer look at the scope reading for shift solenoid C revealed that when the HSD turned off, voltage dropped to 2.1 volts rather than 0.

The solenoid resistance measured 14 ohm. A 14-ohm solenoid being supplied with 2.1 volts equates to a 0.15 amps current draw (2.1vdc / 14 ohms = 0.15 amps). These 0.15 amps prevented the solenoid’s magnetic field from collapsing, which simply means it remained ON rather than turning OFF.

Further solenoid to hydraulic activity explained: When the high-side driver inside the PCM energizes shift solenoid C, the applied pressure strokes shift valve C to the left. When the PCM turns off shift solenoid C HSD, there is some residual current, the voltage does not drop to zero, the HSD is defective. This leaves the shift solenoid in the applied position, so the shift valve C cannot return to the right or home position. This prevents the 5G port at shift valve C from connecting to the 56 port of the shift valve C, so 4th gear clutch apply pressure from linear solenoid B cannot reach the clutch, hence the transmission neutrals. The new PCM solenoid C HSD turns off properly, hence the problem is gone.

Special thanks to Scot Manna from M.B. Automotive in Chicago.

Mercedes 7-speed transmission known as the 7 G-Tronic is commonly referred to as the 722.9 transmission. This 5th generation of Mercedes’ transmission line up made its first appearance in 2003. By 2010 a revised version of this transmission was developed making it the 6th generation of transmissions calling it the “7 G-Tronic Plus.” There are currently 7 generations of transmission by Mercedes. They are as follows:

- 1961: 4 Speed – K4A035

- 1969: 3 Speed – W3A040

- 1980: 4 Speed – W4A040

- 1996: 5 Speed – W5A580 (NAG1)

- 2003: 7 Speed – W7A700 (7G-Tronic)

- 2010: 7 Speed – W7C700 (7G-Tronic Plus)

- 2013: 9 Speed – W9A700

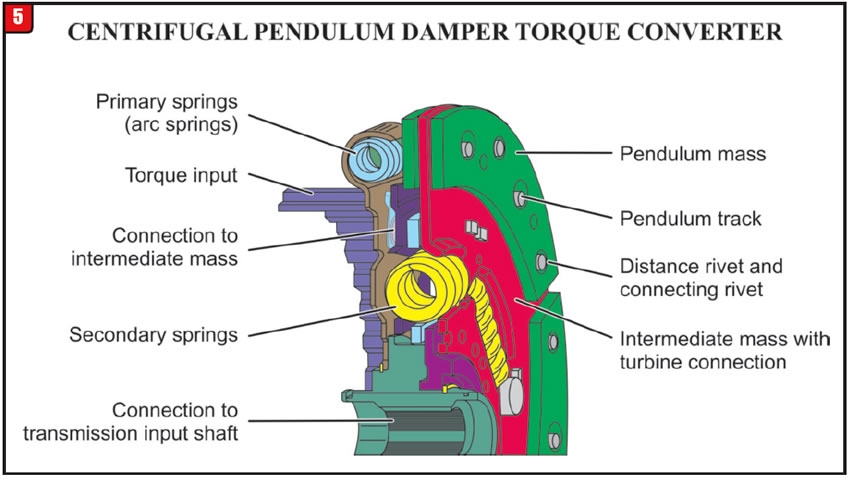

The most significant change made with the 6th generation was to the torque converter, which incorporated a new feature known as “centrifugal pendulum damper” (Figure 5).

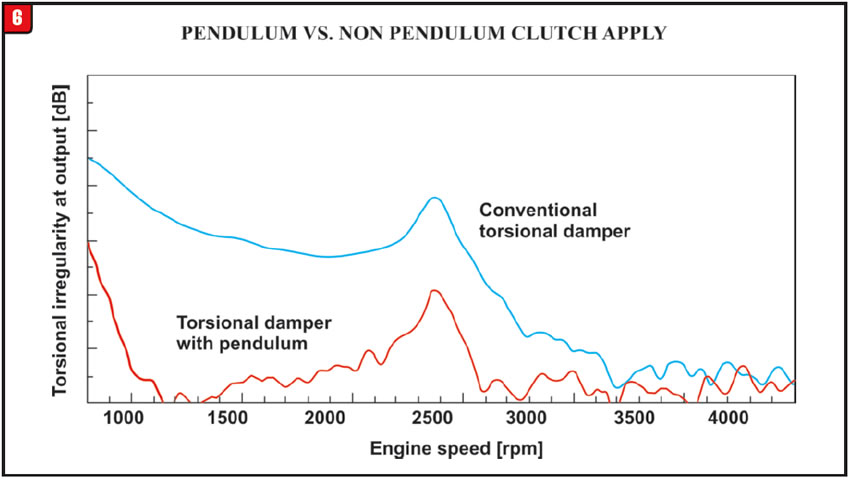

It is used to prevent noise, vibration and harshness (NVH) as the TCC apply strategy has changed from high-slip speeds when the TCC is applied to little to no slip (Figure 6).

In other words, the converter clutch is fully applied sooner, rather than slipping the clutch on. These changes were made in part to accommodate dramatic increase in torque generated by the new V-8 engine and the torque increase of the four- and six-cylinder diesel engines.

The torque converter lock-up clutch continues to utilizes a three-channel system, which has been improved in key areas. The path that the cooling oil takes to the clutch assembly has been redesigned to flow directly toward the coupling package. This provides for especially effective and efficient cooling. Another change was to increase the gap between the clutch disks increasing the overall clutch assembly clearance reducing drag torque significantly. The result is much improved performance, especially under cold-starting conditions when engaging a gear. Previous versions had a tendency to pull down en-gine rpms or even stall the engine under these conditions.

The 7 G-Tronic Plus transmission can be fitted with vehicles that features “start-stop” technology, which is paired to an electric pump to sustain line pressure when the vehicle is stopped (engine off). If so equipped, the electrical motor is fastened to the bottom side of the converter/pump housing.

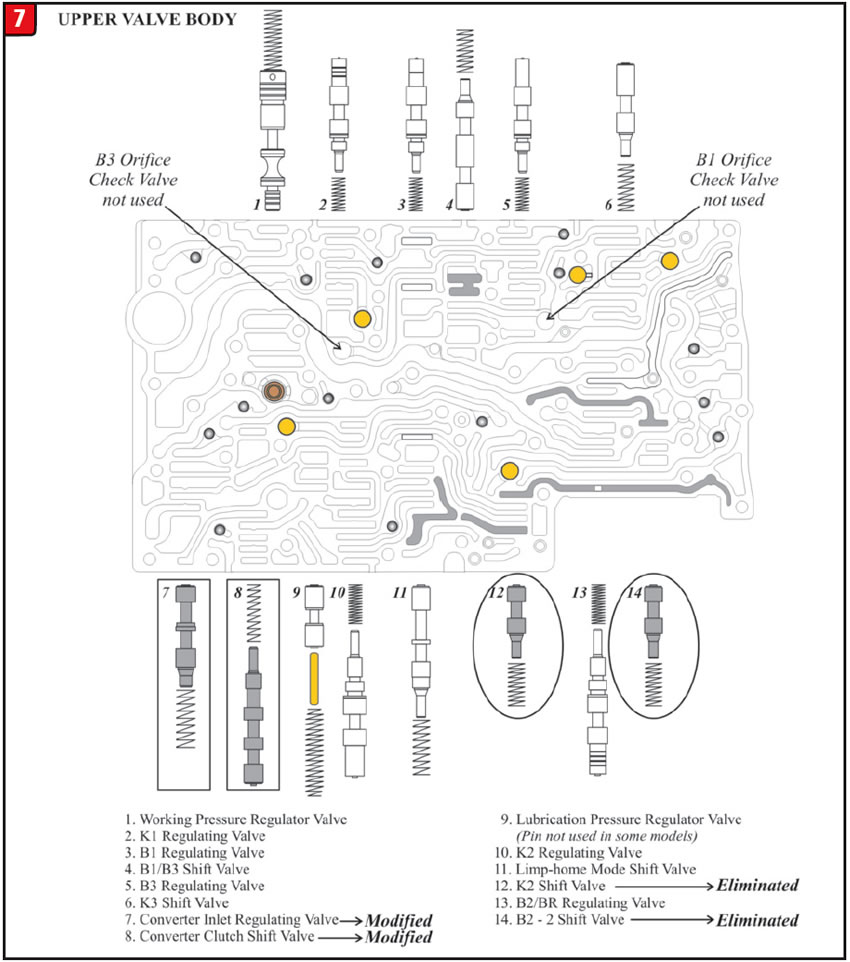

As a result of these changes, particularly with the new “centrifugal pendulum damper,” significant changes were made to the valve body, which is the primary focus of this technical presentation. The K2 shift valve and the B2-2 shift valve have been eliminated as seen in Figure 7. This caused casting changes required to close off circuits once going to these valves. The shaded circuits identify these closed off passages in Figure 7.

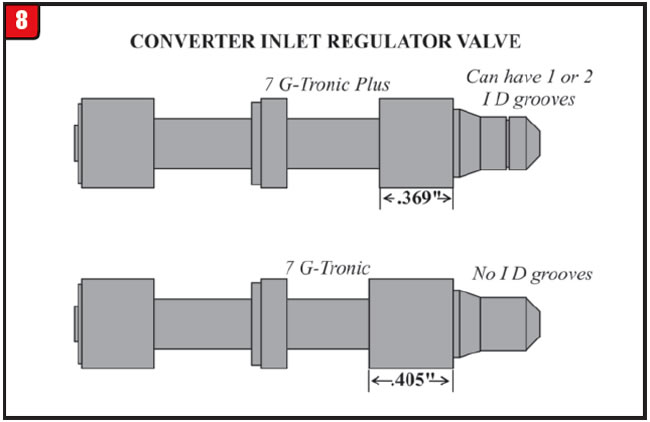

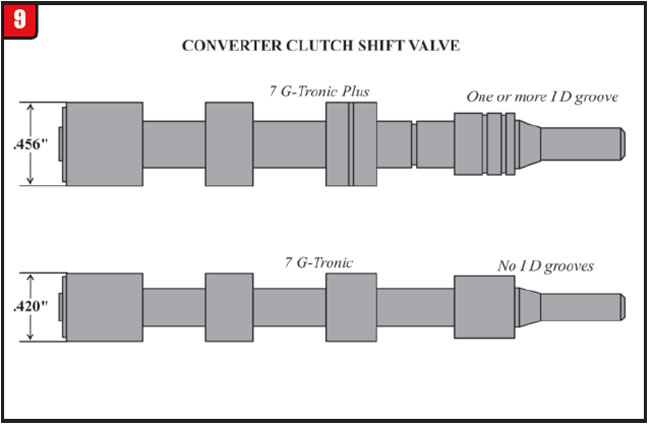

With having a different converter clutch apply strategy, both the converter inlet regulating valve and the converter clutch shift valve were dimensionally modified (figures 8 and 9).

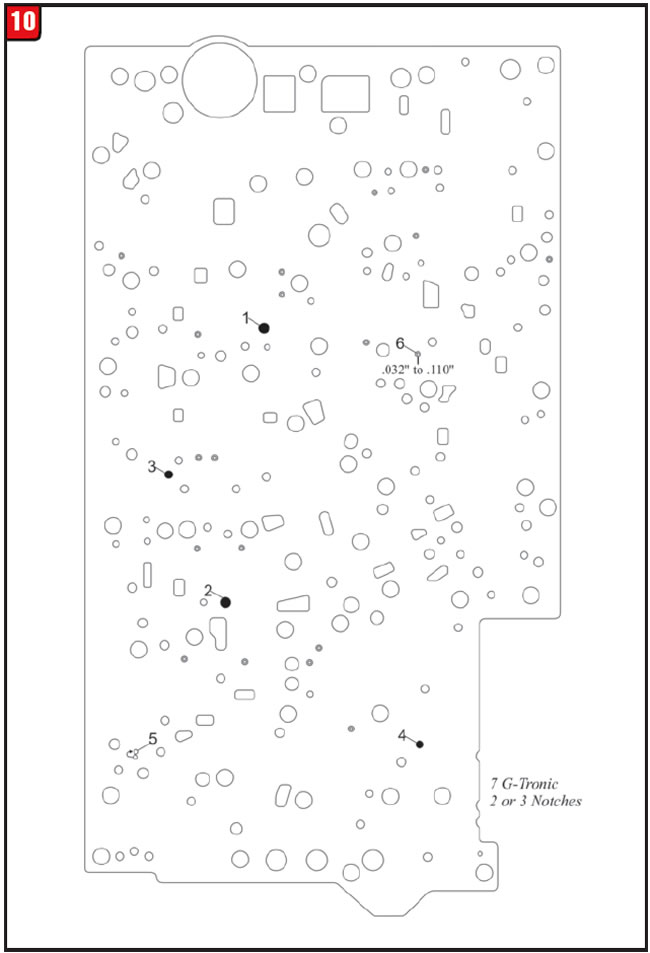

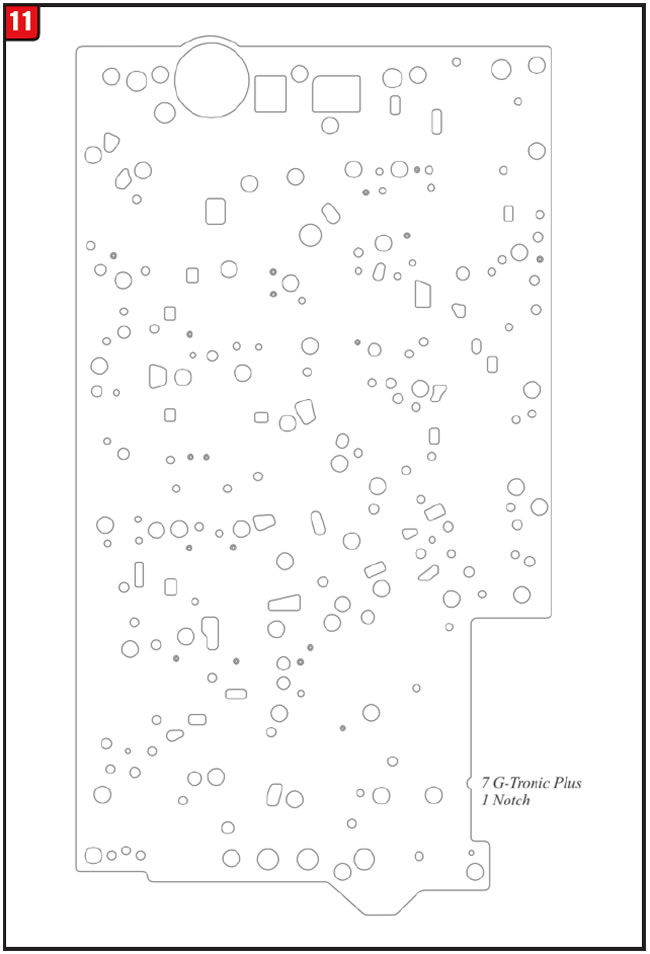

The spacer plate received modest changes as well. Figure 10 is a typical spacer plate used in 7 G-Tronic transmissions identified by 2 or 3 notches.

Holes within the plate are marked out to show changes made to the plate with the 7 G-Tronic PLUS plate. Holes 1 and 2 may or may not be present with 7 G-Tronic units as some models have the B1 and B3 orifice check valves while others do not. Hole 1 is for the B1 orifice check valve and hole 2 is for the B3 ori-fice check valve. If these holes are not in the plate, the valve body does not use these check valves. The 7 G-Tronic PLUS does not use these orifice check valves so these holes will not be present (Figure 11).

- Hole 3 was eliminated due to a casting change to the B1/B3 shift valve.

- Hole 4 was eliminated due to the elimination of the B2-2 shift valve.

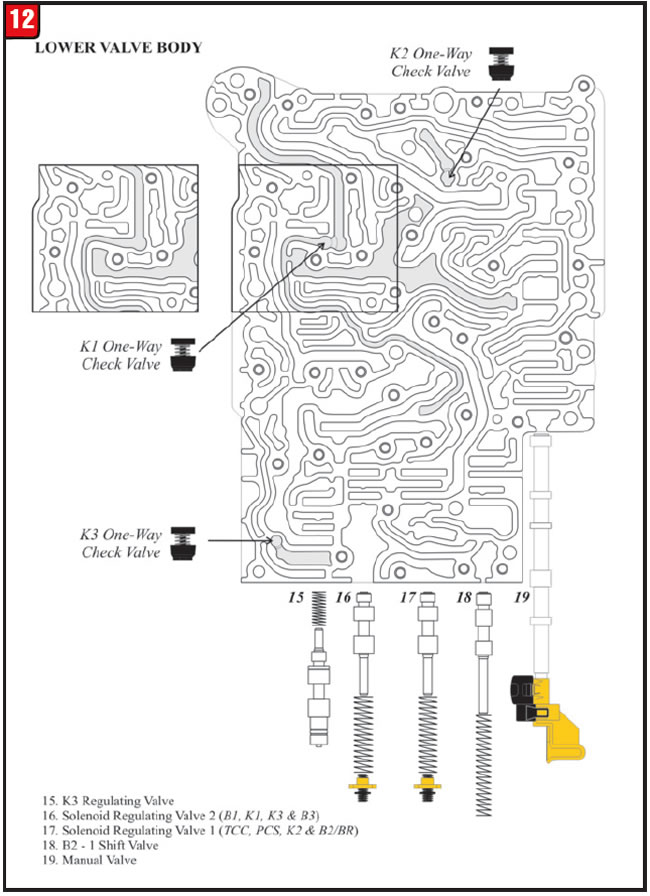

- Hole 5 took a slight move to sit over an added one-way check valve for the K3 clutch feed circuit in the lower valve body (Figure 12).

- Hole 6 was increased from 0.032” to 0.110”. This is an exhaust circuit for the K2 regulating valve that has been routed to where the K2 shift valve was once located.

Figure 11 is what a typical spacer plate will look like for the 7 G-Tronic PLUS transmission and is identified with a single notch.

Each of the K1, K2 and K3 clutch feed circuits have an added one-way check valve to control engagement and pre-fill pressures as seen in Figure 12.

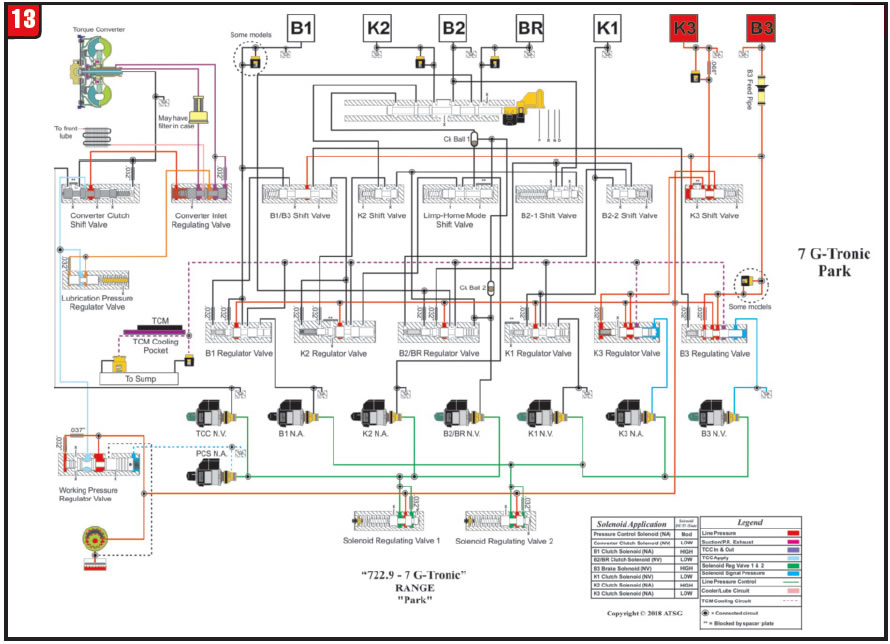

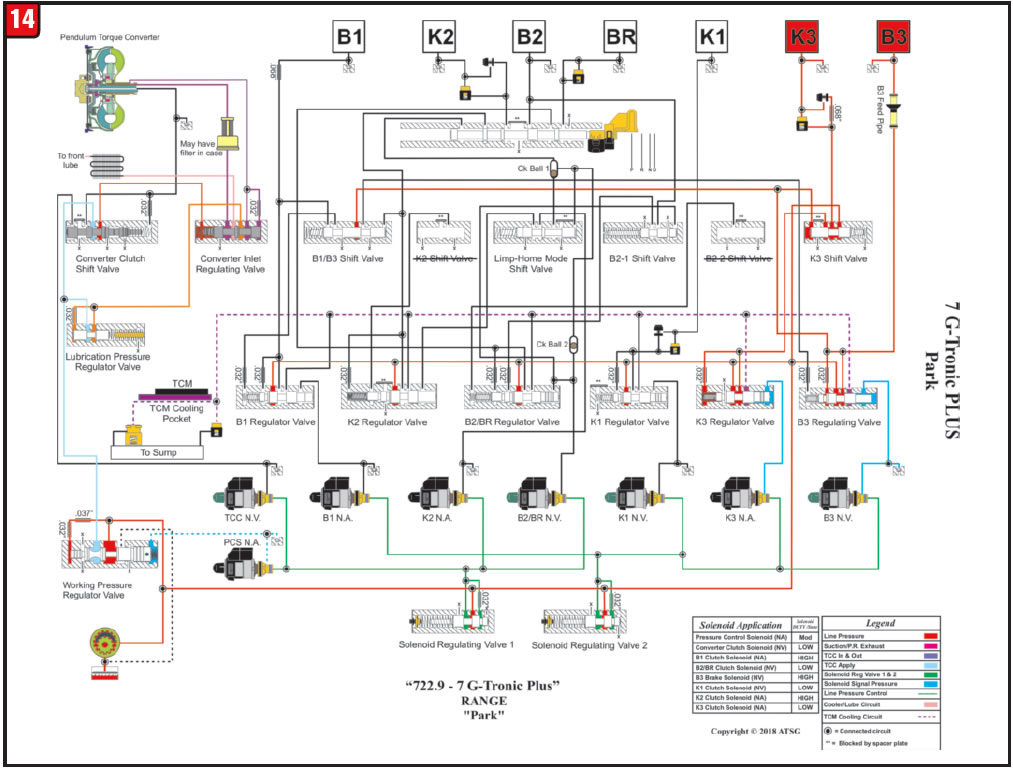

For comparison, a 7 G-Tronic hydraulic schematic is provided in Figure 13 and a 7 G-Tronic PLUS hydraulic is provided in Figure 14.

September 2018 Issue

Volume 35, No. 9

- MRMA 5-speed Acura RSX: Neutralizing into fourth gear

- 722.9 new design valve body: 7 G-Tronic plus generation six