Shift Pointers

- Author: Wayne Colonna

- Subject Matter: 7 G-Tronic (722.9)

- Issue: Torque converter

Converter modified to accommodate dramatic increase in torque

Mercedes’ 7-speed transmission known as the 7 G-Tronic is commonly referred to as the 722.9 transmission. This 5th generation of Mercedes’ transmission lineup made its first appearance in 2003. By 2010 a revised version of this transmission was developed making it the 6th generation of transmissions calling it the 7 G-Tronic Plus (Figure 1 – ATSG thanks TransTec for the use of this transmission).

There are currently 7 generations of transmission by Mercedes:

- 1961: 4 Speed – K4A035

- 1969: 3 Speed – W3A040

- 1980: 4 Speed – W4A040

- 1996: 5 Speed – W5A580 (NAG1)

- 2003: 7 Speed – W7A700 (7G-Tronic)

- 2010: 7 Speed – W7C700 (7G-Tronic Plus)

- 2013: 9 Speed – W9A700

Significant changes were made to the torque converter (Figure 2) and valve body with this 6th generation transmission.

The changes made to the valve body are related to the changes made to the torque converter, which will be the subject of the next issue of Shift Pointers. The change made to the torque converter is a feature known as centrifugal pendulum damper was built into it.

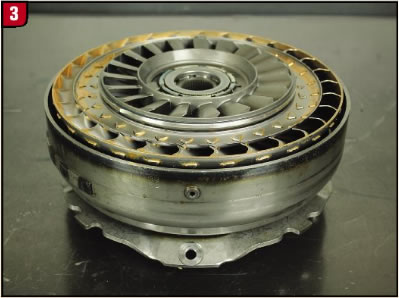

Removing the converter pump assembly, the stator and turbine assemblies come into view (Figure 3).

Lifting the turbine assembly out of the cover, the converter clutch hub can be seen on the back side of the turbine assembly (Figure 4).

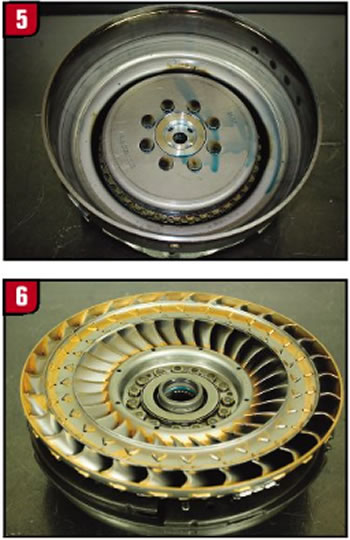

Torsion springs and the pendulum weights are also a part of this assembly. Looking into the cover, it can be seen that the pressure plate for the four-friction converter clutch stack-up assembly is held into place with eight rivets (Figure 5).

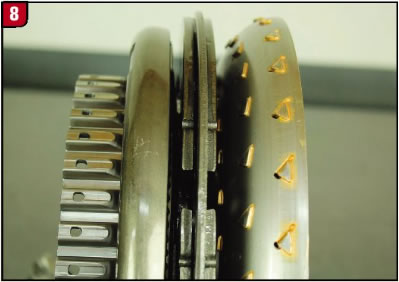

Figures 6, 7, 8 and 9 are different views of the turbine assembly, which shows how the centrifugal pendulum dampers were built into it.

Daimler makes these following comments pertaining to its centrifugal pendulum damper design. These centrifugal pendulum dampers are used to prevent noise, vibration and harshness (NVH) as the TCC apply strategy has changed from high slip speeds when the TCC is applied to little to no slip. In other words, the converter clutch is fully applied sooner, rather than slipping the clutch on. These changes were made in part to accommodate dramatic increase in torque generated by the new V-8 engine and the torque increase of the four- and six-cylinder diesel engines.

The torque converter lock-up clutch continues to utilize a three-channel system, which has been improved in key areas. The path that the cooling oil takes to the clutch assembly has been redesigned to flow directly toward the coupling package. This provides for especially effective and efficient cooling. Another change was to increase the gap between the clutch disks increasing the overall clutch-assembly clearance reducing drag torque significantly. The result is much improved performance, especially under cold-starting conditions when engaging a gear. Previous versions had a tendency to pull down engine rpms or even stall the engine under these conditions.

The 7 G-Tronic Plus transmission can be fitted with vehicles that features start-stop technology, which is paired to an electric pump to sustain line pressure when the vehicle is stopped (engine off). If so equipped, the electrical motor is fastened to the bottom side of the converter/pump housing.