Below are three examples of trucks that came into transmission shops, yet either did not have a transmission problem, or had a simpler issue than it originally seemed. Read on for the stories.

Case study 1: Chevrolet 2500 HD

Our first example features a 2006 Chevrolet 2500 HD 2WD. It has 76,257 miles on the odometer, a 6.0L engine and the 4L80E transmission.

The truck arrived at the shop with the customer reporting that the converter locked up and at a stop it slowly went into gear; it would not engage Park.

A check of the fluid level and condition revealed it to be full and clean, indicating a well-maintained vehicle. A complete health check of the vehicle revealed only one code: P0420 Catalyst system efficiency low B1.

Now for a road test. The initial impression when starting to drive this truck was that the engagements were delayed on both forward and reverse. When the engagement finally occurred, it did so harshly. Shifting back into Park, it revealed an intermittent hold in Park. When it didn’t hold, there was none of the common ratcheting sound associated with a damaged parking pawl or shallow engagement of the pawl.

During the test drive, everything felt fine until the truck slowed down. It was then that a “disconnect” in the drivetrain was observed. When coming to a complete stop, it would reconnect with a bump.

The driver then devoted some time to depressing the accelerator pedal and gently releasing it. With a little patience, this disconnect could be duplicated consistently. On the return to the shop, the technician discovered two more clues when playing with the accelerator. The first was during acceleration with authority. One rear wheel would spin out but never the other. Additionally, the rear of the truck was “steering” left and right when accelerating and decelerating.

Upon return to the shop parking lot, a second technician was recruited to help with the diagnosis. He was instructed to watch the driveshaft during forward and reverse engagement, at which time he noticed an unusual amount of rotation. How could this be when there was no differential noise?

One important detail: this truck is equipped with GM’s “G80 differential option.” GM calls this a positraction differential. It is their brand name for a limited slip differential (LSD). This option was designed to engage both rear wheels in slippery conditions. For the “old school crowd,” this is known as a locker or gov lock.

When does the G80 lock, you’re asking? When the rear wheel speed difference reaches 120 RPM, thus delivering up to 100 percent of the driveline’s power to both driven wheels for maximum traction when needed. In this case study, it was discovered that the cause of these issues was due to a sheared off axle. A slide hammer was welded onto the end of the axle shaft to pull it out, as Figures 1 and 2 show.

This means only one axle was doing the driving. When the differential carrier “locked,” it was able to drive the truck with only one wheel doing the driving. This explains the ease of the rear tire losing traction as well as the “steering” action from the rear of the vehicle.

After completing the diagnosis, technicians took the logical next step, removing the semi-floating driver side rear axle to replace the damaged axle with a serviceable replacement. In this case, the axle required a rod to be welded to it and a slide hammer used to remove the axle. Once the new axle was installed, the truck was driven to confirm an accurate repair and a satisfied customer.

Case study 2: 2011 Ford F-150

Next is a story about a Ford F-150, with the 5.0L engine and the 6R80 transmission. This vehicle arrived at the shop with a concern of “shuddering” along with a metallic noise.

A little background is in order before the story is started. This truck was at a general repair shop with the same concern being diagnosed as a possible converter failure (noise) and shudder. This is a common issue with the 6R80 transmission. Installing a remanufactured transmission and converter makes for an easy solution to the problem at hand. What the previous shop found was that after transmission replacement and solenoid characterization, the truck had all the same symptoms as before the repair.

Now at our shop, the diagnosis begins.

Read more stories from our Technically Speaking column series here.

Fluid condition and level was inspected first and confirmed to be good, followed by checking for any stored diagnostic trouble codes where none was found. On the test drive the vehicle exhibited an odd surging or trailer hitching at certain speeds accompanied by a rattle, like what an exhaust heat shield would do. There was also a significant loss of power noticed at 45-50 MPH, enough so that the driver would need to depress the throttle further to maintain speed and this was also cyclical.

All transmission data was within expected values (converter slip, vehicle speed etc.). Technicians looked at engine data for any of the PID values to fluctuate in conjunction with the engine power fluctuation. They found that the cam position data indicated a wide variation in timing that coincided with the noise and the loss of power/surging. Next, it was time for a quick return to the shop for further diagnosis.

The next step is probably the easiest: pull the engine oil dipstick. There was no oil showing on the dipstick, and an oil and filter change resulted in less than two quarts of oil in the pan. Knowing that this engine relies on oil pressure to tension the timing chain as well as to actuate the camshaft phasers, oil level is critical to proper valvetrain function and other engine functions as well.

Technicians performed an oil change with 5W-20 synthetic oil. Service data shows that this system requires more than 7 quarts of oil when the filter is changed as part of the service. With the proper amount of oil in the engine, the truck was taken out for a test drive to confirm a proper diagnosis and successful repair.

It’s likely that this truck never needed a transmission replacement. With a little proper maintenance and service intervals, this truck would not have been taken into the last shop for drivability issues, and unnecessary repairs would never have been performed on this truck.

Case study 3: Ford F-350 Super Duty

I know that technically this is a transmission problem but there are valuable pieces of information in this one; read on.

This truck was a 2014 Ford F-350 Super Duty 4X4. It had the 6.2L engine, the 6R140 transmission, and 168,398 miles logged. It came to the shop with a no-reverse complaint.

This truck had just had a factory transmission installed, so it was important to carefully diagnose this vehicle for an accurate repair. Scanning with a compatible scan tool found no codes, and a check of the fluid showed that the fluid was full and clean. Now for a test drive.

When Reverse was selected the truck would not back up, an engagement could be felt but no reverse. When Drive was selected, the truck drove normally down the road, completing all the upshifts and lockup.

Technicians decided to start the truck and unplug the main transmission connector to isolate the transmission from the computer system. When this was done the truck did not move at all. What?

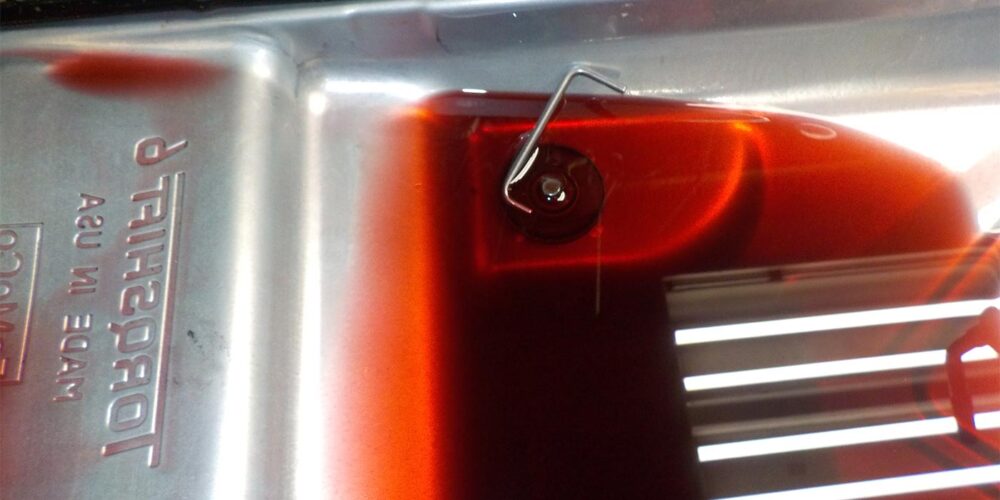

With the transmission connector plugged back in and the codes cleared, the truck was able to be driven again. Next, we needed to put this truck on the lift for some valve body checks. When the technician pulled the pan, they found a surprise stuck to the magnet in the pan: It was the link that connects the manual valve to the detent assembly which is part of the range sensor (as seen in Figures 3, 4 and 5).

When this transmission was remanufactured by Ford, the retainer on the detent was not slid down over the link to retain it. After a quick re-installation of the rod and retainer (see Figures 6 and 7), the pan was installed and the unit filled, restoring Reverse back to the vehicle.

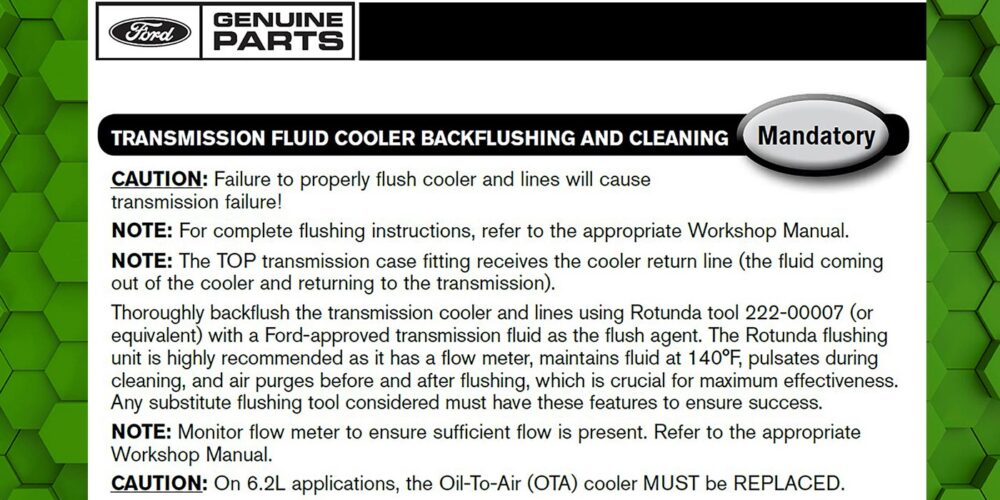

There is an addition to this story where the installation shop, despite following all installation procedures to a T, missed an important detail. The one line in the paperwork that they overlooked was specifically for the 6.2L gas engine. That line requires the oil-to-air cooler to be replaced (see the last line in Figure 8).

From experience, I can tell you if there is not supporting documentation of this replacement, Ford will deny any warranty claims for the transmission. So, remember: it is important to read all documentation that is enclosed in the box that the transmission comes in.