Easy TH400, 4L80-E reverse servo setup: Craft your own tool

While not as sensitive as some shifting bands, the Reverse band adjustment on a TH400 or 4L80-E transmission is critical, and failure to get it right has tripped up even the best builders. There is nothing worse than getting the transmission installed, putting it in Reverse and then not going anywhere or having no engine

Shift pointers: High-mileage transmissions and the aches and pains of age

Among the most common four speed-transmissions keeping shops busy today are the Ford 4R70E/W, the GM 4L60-E and the GM 4L80-E. In most cases, this typically equates to working on high-mileage vehicles. Aches and pains come with age and/or high mileage. In fact, when we see a person who looks beat and tattered, some may

Look for the little details: Three transmission repair case studies

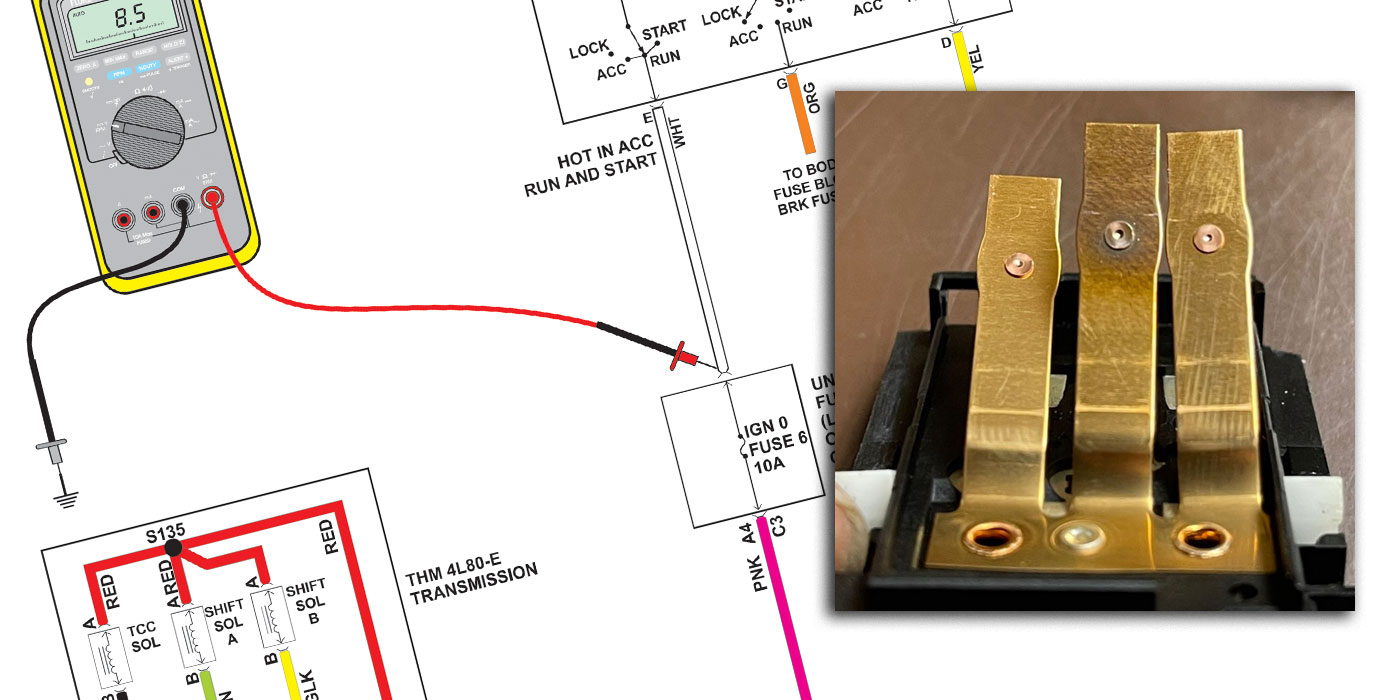

Below are three examples of trucks that came into transmission shops, yet either did not have a transmission problem, or had a simpler issue than it originally seemed. Read on for the stories. Case study 1: Chevrolet 2500 HD Our first example features a 2006 Chevrolet 2500 HD 2WD. It has 76,257 miles on the

From one problem to the next: When a simple solution becomes complicated

A 2007 Chevrolet Express 3500 comes to our shop with a concern of no reverse and very little forward movement. A quick check of codes reveals the following: P0171 Fuel Trim System Lean B1 Po174 Fuel Trim System Lean B2 P0218 Transmission Fluid Overtemp P0300 Engine Misfire Detected P0455 Evap Leak P0753 1-2 Shift Solenoid

Sonnax highlights adjustable rear servo pin kit

Sonnax highlights its adjustable rear servo pin kit (part number 34912-01K), which allows users to replace servo pins in GM TH400 and 1995 and earlier 4L80-E transmissions. OE pins have seven different lengths to allow for adjustment of the Low/Reverse band but are no longer available from GM. This pin kit has an adjustment range

Sonnax introduces Low/Reverse servo pistons for GM TH400, 4L80-E

Sonnax has introduced new Low/Reverse servo pistons for GM applications. According to the company, the new pistons are built for GM TH400 and 4L80-E transmissions, and are made of high-strength, billet aluminum to prevent failure.

GM 4L80/85-E Extreme Duty Input Shaft

Input shaft failure is common in performance GM 4L80-E and 4L85-E units running with extreme horsepower. OE and aftermarket shafts simply don’t hold up in these conditions, leading to spline twist and shaft breakage. Recommended for applications above 1,000-hp, the Sonnax extreme duty input shaft (p/n 34670-02) is manufactured from high-strength Aermet steel alloy with

GM 4L80/85-E 2-3 Accumulator Spring

This new Sonnax 2-3 accumulator spring (p/n 34931-01) for GM 4L80/85-E units is a direct replacement spring that has been stress relieved and shot-peened for increased durability compared to factory springs.

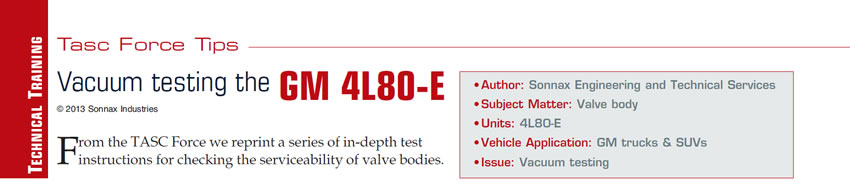

Vacuum testing the GM 4L80-E

From the TASC Force we reprint a series of in-depth test instructions for checking the serviceability of valve bodies.

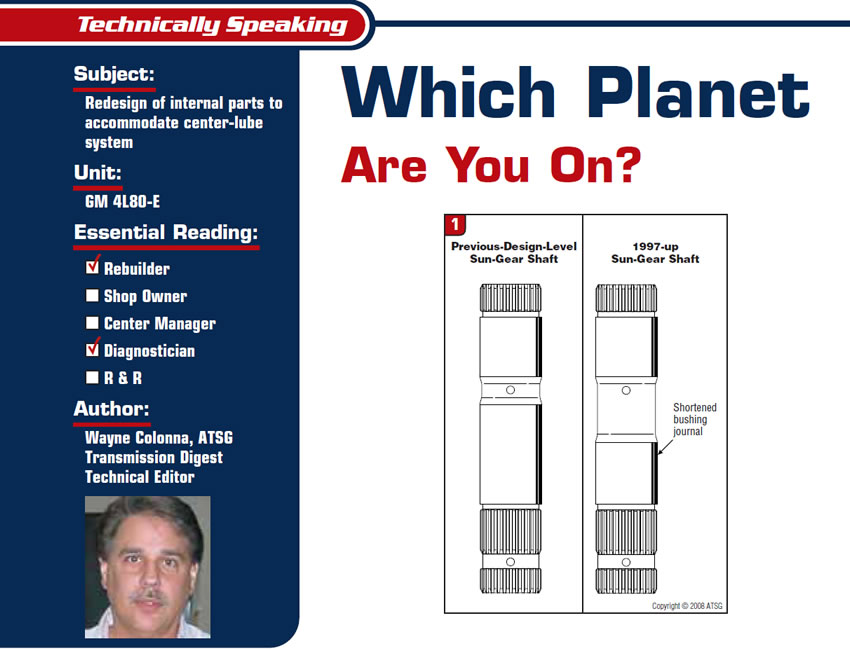

Which Planet Are You On?

As most rebuilders know, in 1997 the 4L80-E went to a center-gearbox lubrication system by relocating the cooler return line from the pump to the center support. As a result, many internal hard parts were redesigned to accommodate this new lubrication system, as illustrated in figures 1 through 5 taken from an ATSG bulletin.

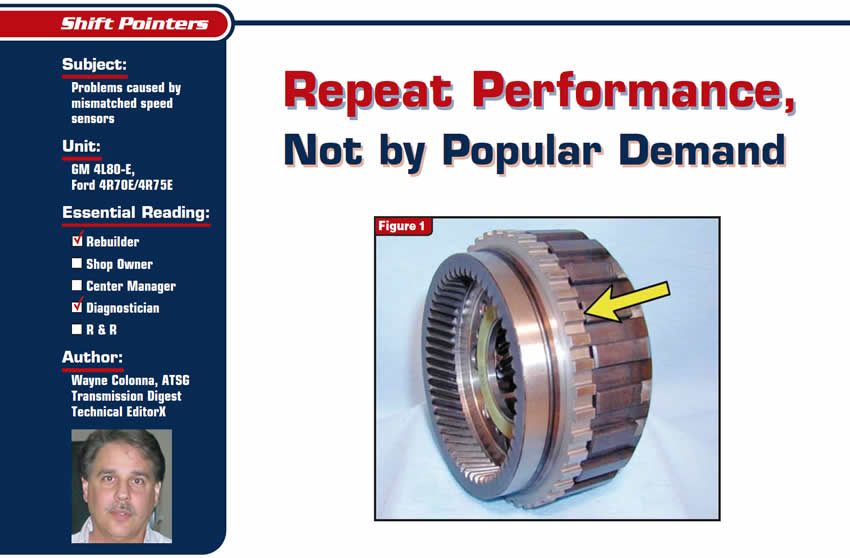

Repeat Performance, Not by Popular Demand

You may recall that the 4L80-E made its appearance in 1991. And whether it was in two-wheel-drive or four-wheel-drive configuration, the output carrier had the exciter ring for the output-shaft-speed (OSS) sensor pressed onto it.