We are all too familiar by now with the numerous band numbers on Ford 6R80 and 6R140 transmissions. We know that — unless you are programming in a new calibration code — it is best to replace a solenoid with the exact same band number as what was taken out of that position on the valve body. Knowing which solenoid could be at fault can get tricky at times, and pinpointing an exact solenoid based on a specific complaint may cause you to pull the valve body a few times, which is no fun. ATF running down your arms and into your armpits can get irritating.

For today’s transmission repair tale, the complaint we have is related to the 2-3 shift. The shift sometimes flares and sometimes has a quick bind-up. Immediately after installing the transmission, we reset the adapts and did the 20–25 stop-and-start road test going from first all the way up to sixth gear, then came down to a stop 20 times, which usually fixes an adaptation problem. Our situation now is that we still have the same complaint; it is like it can’t make up its mind.

The first thing to do is to look at an apply chart, where we see that the 1-2-3-4 clutch is on in first gear and the 2-6 clutch comes on in second gear. Then for the 2-3 shift, the 3-5-R clutch comes on as the 2-6 is released. Reviewing this data, we see that during a 2-3 shift, the 3-5-R is applied, but the 2-6 must release at the same time. Now that we know this, we understand that both the 3-5-R and 2-6 solenoids are in question.

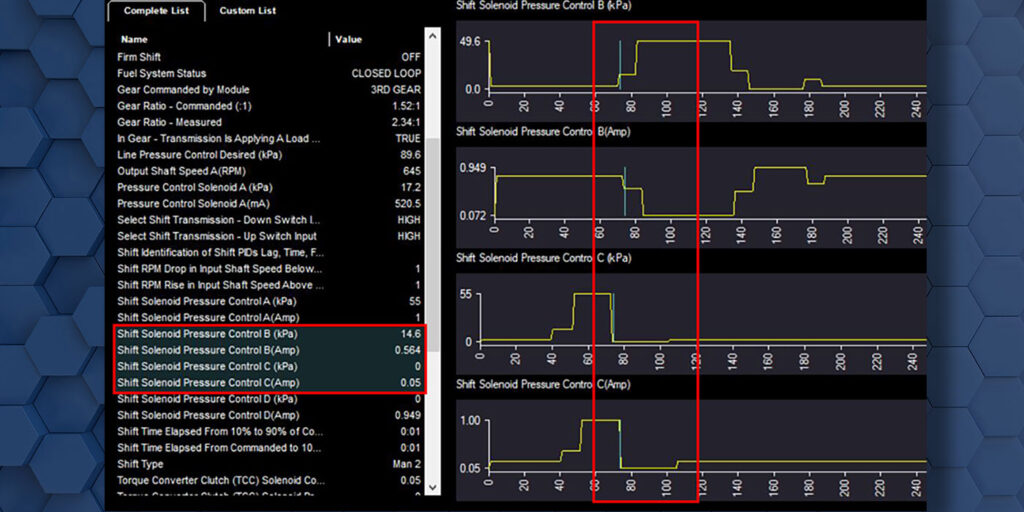

After driving this vehicle a little longer — and paying attention to the 2-6 apply — we notice that the 1-2 shift is sometimes a little slow, then at times it has a bump at the end of it. During our road test, we record the upshift transitions on the scan tool and they look normal. Figure 1 shows the beginning of the 2-3 upshift (the figures shown here are from a 6R80 application, but 6R140 is similar).

Notice that the “C” solenoid (NL) for the 2-6 clutch amperage is 1.0 Amp and solenoid PSI (not kPa) is low. The “B” solenoid (NH) amperage for the 3-5-R clutch drops to .564 mA, and the “B” solenoid pressure builds to 14.6 PSI. Figure 2 shows the “C” solenoid amperage dropping off and the pressure dropping to 0.

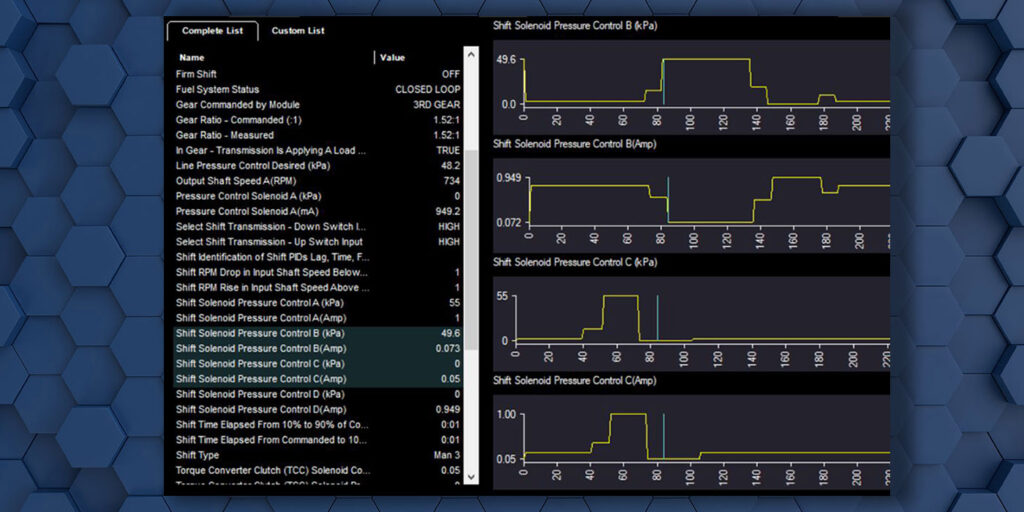

Figure 3 shows that the completed 2-3 shift solenoid “B” amperage is .073 and solenoid “B” pressure is near 50 PSI. The “C” solenoid amperage and pressure stay low while in third gear.

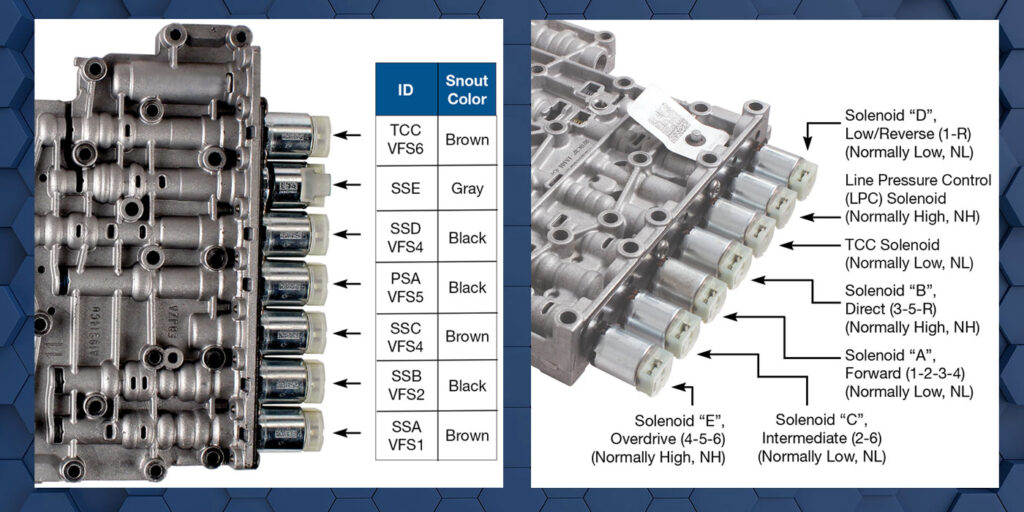

After reviewing this data, the electronics prove to be working correctly, as we see that the “C” solenoid is fully off just before the “B” solenoid is fully off, and this pattern proves to be consistent. In this situation, we choose to change both the “C” 2-6 solenoid and the “B” 3-5-R solenoids so that we only have to pull the valve body off once, as this seems to be more of a solenoid mechanical problem. See Figure 4 for solenoid locations for both 6R80 and 6R140.

Another consideration is clutch clearances: Be careful not to tighten clutch packs up too much, as this can also cause a binding condition. Stick closely to the OE specifications, or else this issue can cause you to have to remove the transmission right after installing it into a vehicle.

After replacing both the “C” 2-6 and “B” 3-5-R solenoids, resetting adapts and going through the 20 stop-and-start road test, the problem is resolved. It is important to look at an apply chart and really get a good feel on a road test to make sure that diagnosis is not going to cost more time. Sometimes it may be more than one solenoid causing shift complaints, or even a clearance issue inside of the transmission.