As the old saying goes: “timing is truly everything.” Or is it? Either way, we know for sure that this is extremely true in the world of transmissions. Timing problems with clutch apply or with combined clutch apply and clutch release can create all kinds of complaints from flared shifts to harsh shifts to a slight bind up or a tire-screeching bind up on a shift transition. No transmission is immune from timing-related shift complaints, but this article will focus on the Ford 6R80 and 6R140.

Personally, dealing with items like these in the past brings to mind a story of a good friend who drove an old Ford F-150 that occasionally would not shift on time from first to second gear. It was sometimes just a little late. He knew that the next time that it went for second gear it would shift hard as a rock, enough to knock a cup of coffee out of his hand and right on his lap. So he would always prepare for that harsh upshift by lifting the coffee high enough, akin to going over a speed bump. Afterwards he would ease off the gas slightly to allow it to shift into second gear so the shift would not be so harsh, then continue his drive into work.

There is something to be said about knowing all the little idiosyncrasies of a vehicle, especially if it is a daily driver. Anyone who has been in this business for a while still counts shifts when driving, a habit that cannot be broken for some reason. You can pretty much predict when the next shift transition is going to take place and anticipate how firm or smooth it will be, depending how hard you are on the throttle. I am sure that most have noticed that shift feel has virtually disappeared on most later-model transmissions. Additionally, when there is an issue with shift feel such as harshness, a flared shift or a binding condition on an upshift, there is usually an adaptation problem, clutch clearance problem, a worn-out valve train in the valve body causing a leak in the clutch control circuit or a solenoid mechanical or flow rate problem.

Read more columns from the TASC Force Tips series here.

Ford 6R80 and 6R140 transmissions have had their fair share of shift complaints after overhaul, with trouble getting adapts to lock in after numerous upshifts and downshifts, which has led back to reusing solenoids. The variable bleed solenoids on the 6R80 and 6R140 have a tendency to lose their calibration or banding over time, creating calibration problems within the PCM for shift control/overlap and adaptation.

By now we have all dealt with the solenoid strategy codes as well as solenoid body ID codes on the valve body and on the tag on the transmission case. These need to be programmed into the PCM so it knows the banding. Whether it be bands 1–5 on both the normally low and normally high solenoids, the PCM needs to know which position it is in and which clutch it is controlling.

All of this is necessary just to help speed up the adaptation process and decrease the number of times the vehicle needs to be driven going up and down through all the gears, which works well. Sometimes the relearn process can be accomplished within three to five shift cycles.

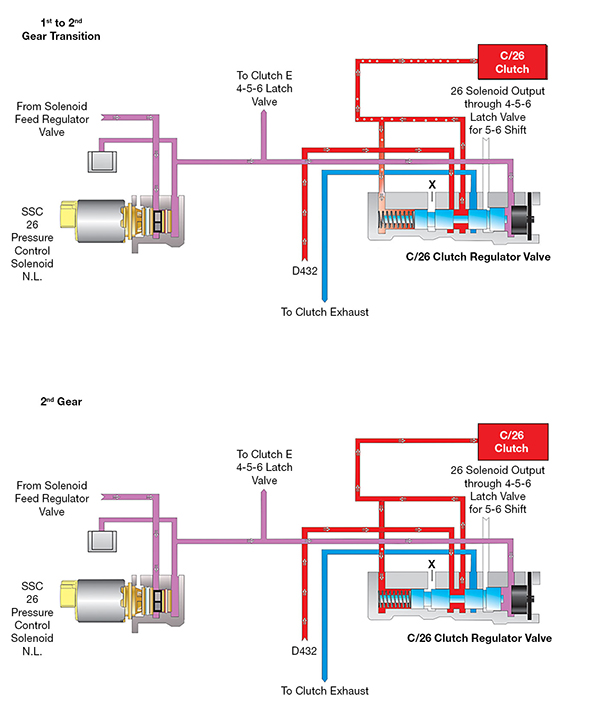

So, for a moment, let’s imagine a road test with solenoids that have lost their calibration or banding — what was previously a band 3 is now a band 5, or maybe a band 3 that is now a band 1.5. The PCM is looking for an RPM drop on the turbine speed sensor within a split second of solenoid command, and solenoid flow rate and banding are integral to positioning the regulator valve for clutch apply. Figure 1, below, shows a transition from first to second gear on the 6R80.

Note that the C/26 regulator valve does not connect to a latch valve like many other valve trains in the 6R80 and 6R140. The C/26 regulator valve regulating position is controlled by SSC solenoid output and a balance circuit, which is connected to C/26 clutch apply. Therefore, an incorrectly calibrated or banded solenoid that either has a slow or overly aggressive output could easily cause a 1-2 slide or an extremely harsh 1-2 upshift. It is also important to note that a slow or overly aggressive solenoid output will also affect the release rate of the clutch it is controlling, meaning that it could also cause a 2-3 upshift flare or a 2-3 upshift that binds up.

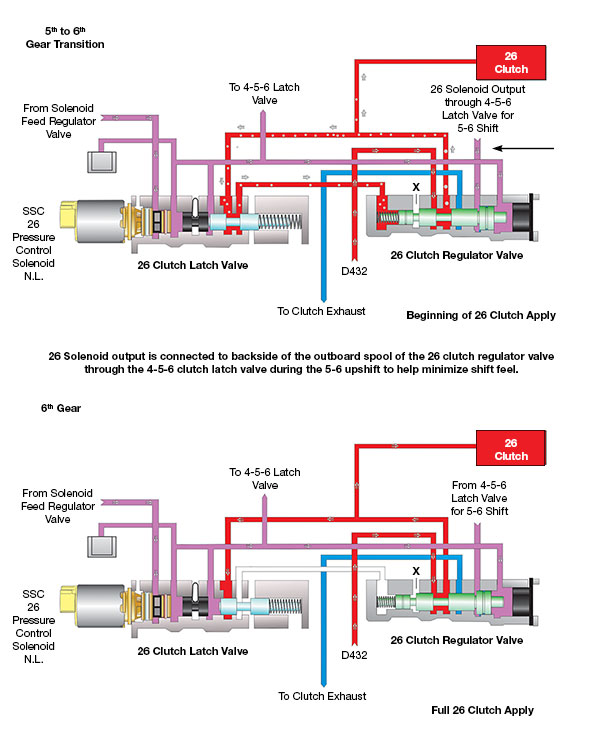

Figure 2 shows an example of the 5-6 upshift on the 6R140.

Note that the 6R140 incorporates a latch valve as part of clutch apply. This latch valve controls the apply rate of the 26 clutch by solenoid output, but notice that there is another connection to the rear of the outboard spool of the valve that is also connected to solenoid output. This helps slow the valve down slightly during the 5-6 upshift. This circuit is connected through the 4-5-6 latch valve and is only used for the 5-6 transition. Slow or aggressive solenoid output can cause numerous shift complaints from flared shifts to harsh shifts to binding conditions. They can also cause inconsistent flare-ups during passing gear because the PCM is confused by the timing of it all and unable to adapt to the solenoid output and clutch regulator and apply patterns. One time the 1-2 upshift is occurring properly, and the next time it will knock a cup of coffee out of your hand!

So the saying “timing is truly everything” should maybe go like this: ”timing is truly everything as long as it is consistent.”

About the author: Jim Dial is a Sonnax technical specialist. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of industry technical specialists, transmission rebuilders and Sonnax technicians.