For shift adaptations to perform adequately, all required inputs must be functional. Of course, the solenoids and transmission components must also be functional. The type of inputs required for shift adaptations to function as designed will have some variations based on year, make and model.

For example, when Chrysler pioneered their 41TE clutch to clutch shifting transmission with no one-way clutch, they used shift solenoids which simultaneously controlled clutch apply. Clutch adaptations were presented via a clutch volume index numbering system. Within this program, they included a unique feature that had to do with the 3-4 shift which required the release of the Underdrive Clutch and the applying of the 2-4 clutch. If this didn’t take place properly, a bind-up could take place. At the vehicle speed with which this could occur, it would be dangerous. So, they wrote a 3-4 shift abort into their adaptation program.

One aspect of the adaptation program is to watch gear ratio changes via the input and output speed sensors. By doing this, they watch the rate of RPM change of each of these two sensors. If the input RPM runs up too high during the change, it indicates a slip or flared shift. From this data, they would change the rate of apply of the 2-4 clutch and the release of the UD clutch to tighten up the shift. Likewise, if the input RPM dropped during the shift, it would indicate too much of an overlap and cause a harsh shift. It would then adjust clutch apply and release parameters to smooth out the shift.

The added 3-4 shift abort is when the computer recognizes that a bind-up is occurring and will abort the shift for safety reasons. It identifies this problem by the rate at which the input speed RPM drops. For example, if it sees the input RPM at 2500 and it looks to drop down to 0 as quickly as possible, the computer sees this as a bind-up in the gearbox and aborts the shift before it has a chance to do so.

From this example, we can clearly see that Input and Output RPM data are necessary inputs in the strategy of shift adaptation. Today, many transmissions utilize shift adaptations. Some even require programming solenoid ID information after replacement or repairs for shift adaptations to function correctly. Others have been using adaptations with their AWD systems. And in doing so, they utilize wheel speed input via the ABS/Traction Control System. When there is a malfunction with this strategy, it too can affect the shifting of a transmission.

Take, for example, a 2012 Dodge Journey AWD equipped with the 62TE transmission that had a complaint of a bump on the 2-3 shift before and after overhaul. After much diagnosing along with countless quick-learn procedures, the shop changed the valve body and the PCM—but the 2-3 shift bump continued.

Eventually, the shop discovered that the rear tires were larger in circumference than the front tires. The computer perceived this as a slip and would engage the rear electronic differential while the 2-3 shift was taking place causing the bump on the 2-3 shift. Apparently, the circumference difference was not extreme enough to set a C1078 code for “Tire Revolutions Range/Performance,” which would have assisted in the diagnosis of this 2-3 shift problem.

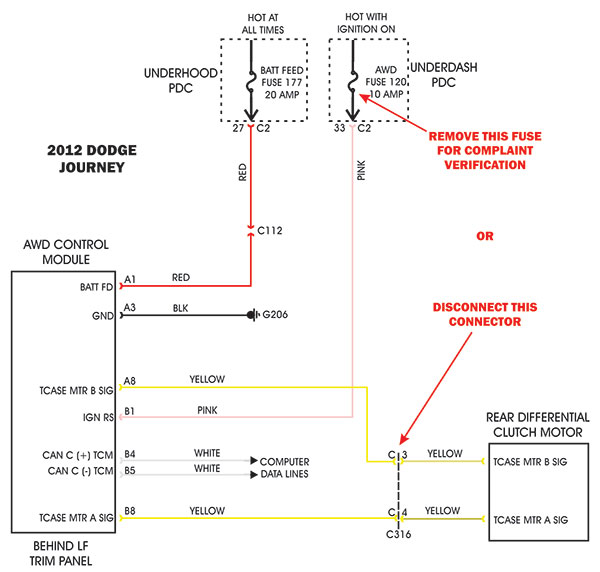

When the shop did to confirm this to be the cause, the rear differential wire harness connector was disconnected, which resulted in the bump disappearing. The AWD fuse could be removed to accomplish the same test as seen in the wire schematic in Figure 1 (above).

With four new tires with the same circumference installed on the vehicle, the road test that followed confirmed the problem had been eliminated. The 2-3 shift was smooth and occurred without a bump.

This scenario could occur on many vehicles equipped with an active AWD system. One quick and definitive method of diagnosing this condition is to use a stagger gauge which can measure the total circumference of a tire as shown in Figures 2 and 3 (below). It is imperative that all four tires be the same circumference size. This will also prevent shift scheduling and shift feel issues as well.