There are many reasons for converter clutch slip codes to occur in vehicles equipped with the Ford 6R140 transmission. One is bore wear in the valve body with any one of the three valves related to converter clutch apply and release. Low line pressure could be another. But there is a third that is inherent to the design of this torque converter.

If you have read an article by Steve Jaussaud called “Identifying Unique Torque Converter Features and Avoiding Application Pitfalls” in the July 2022 edition of Transmission Digest, you may already be familiar with the unique design of this torque converter. It is a captive clutch design with the piston being in the cover. Sitting on the piston is the clutch assembly with a contoured backing plate welded to the converter. When the clutch is applied, the piston pushes towards the transmission, not the flywheel side of the cover. In other words, the piston applies the clutch against the backing plate and not the cover.

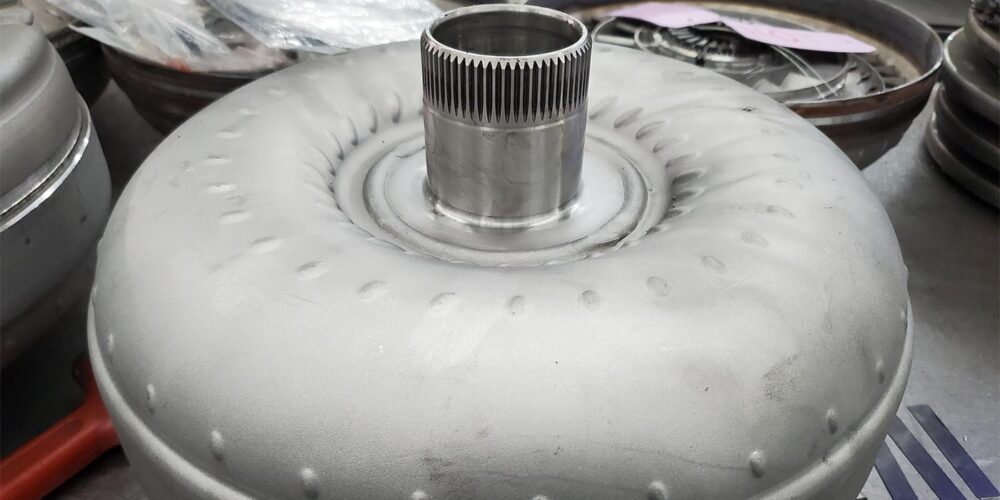

Figure 1 (above) is a close-up view of this clutch assembly. It is a captive clutch in that the friction plate sits in the middle of two steel plates that have leaf springs pop riveted to their outer tangs. This is one of the many reasons this unit may have TCC slip codes.

These leaf style springs snap off the rivet or the rivets themselves dislodge from the steel plate (see Figures 2 and 3).

Pieces break away and causes damage to both the friction plate and converter (see Figure 4).

During the rebuild of this torque converter, Sonnax offers a Smart-Tech Converter Clutch Kit (part no. FD-CP-20K). The following is the step-by-step process for another way this converter can be rebuilt:

Place a steel plate onto the piston (Figure 5), followed by a friction plate (Figure 6) and finishing with another steel plate (Figure 7). Then place four 0.020-in. shims 90 degrees from each other between the friction plate and the upper steel plate (Figure 8).

Once these shims are in place, the backing plate can be put in place (Figure 9).

Weld this backing plate to the cover. To prevent any of the weld from falling into the converter, a smaller cover is put in place as protection. After a few welding tacks followed by running some beads of weld securing the backing plate to the cover (Figure 10), the protective cover and shims are then removed (Figures 11 and 12).

After verifying proper clearance of the friction plate, the turbine and a new turbine seal is installed (Figure 13) followed by the stator assembly (Figure 14) and ending with the converter pump and hub housing (Figure 15).

Regardless of the different ways this converter can be rebuilt, to ensure a total and complete repair, inspect all related valves for bore wear and repair as necessary. Then inspect for good line pressure once the transmission is in the vehicle. Correct any external issues affecting line pressure should there be any.

Read more stories from our Technically Speaking column series here.