Shift Pointers

- Author: Jim Dial, ATSG Senior Technical Consultant

Just when you thought you had all the P1870 torque-converter-clutch slip codes under your belt, another vehicle comes along – and here we go again!

I am sure that most of you are familiar with the 4L60-E P1870 TCC-slip code and torque-converter-shudder problems related to the code. This usually is related to wear-out of the torque-converter regulator-valve bore causing a loss of torque-converter apply pressure, allowing the TCC to slip, and we all know what fixes are available for that.

Now we have 2000 Isuzu Trooper and BMW models equipped with the 4L30-E transmission showing up in shops with the same P1870 code. You guessed it – the same kind of TCC regulator-valve-bore wear is the cause here also. The biggest problem is that there is little printed material to tell us where the TCC regulator-valve train is and how it works. We all know that if you don’t know how it works, you can’t even begin to fix it!

History: In the 2000 model year, Isuzu Trooper and some BMW models went to a pulse-width-modulated (PWM) TCC apply strategy. Isuzu Rodeo, Honda Passport and Cadillac Catera stayed with the typical on-off TCC apply that they have had since day one. This strategy change, on these limited models, has created some serious confusion in parts interchange and the identification of parts.

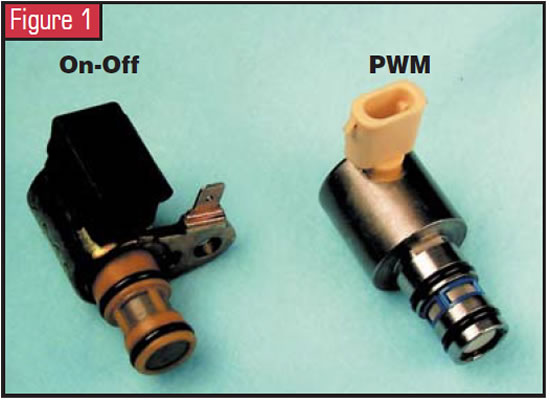

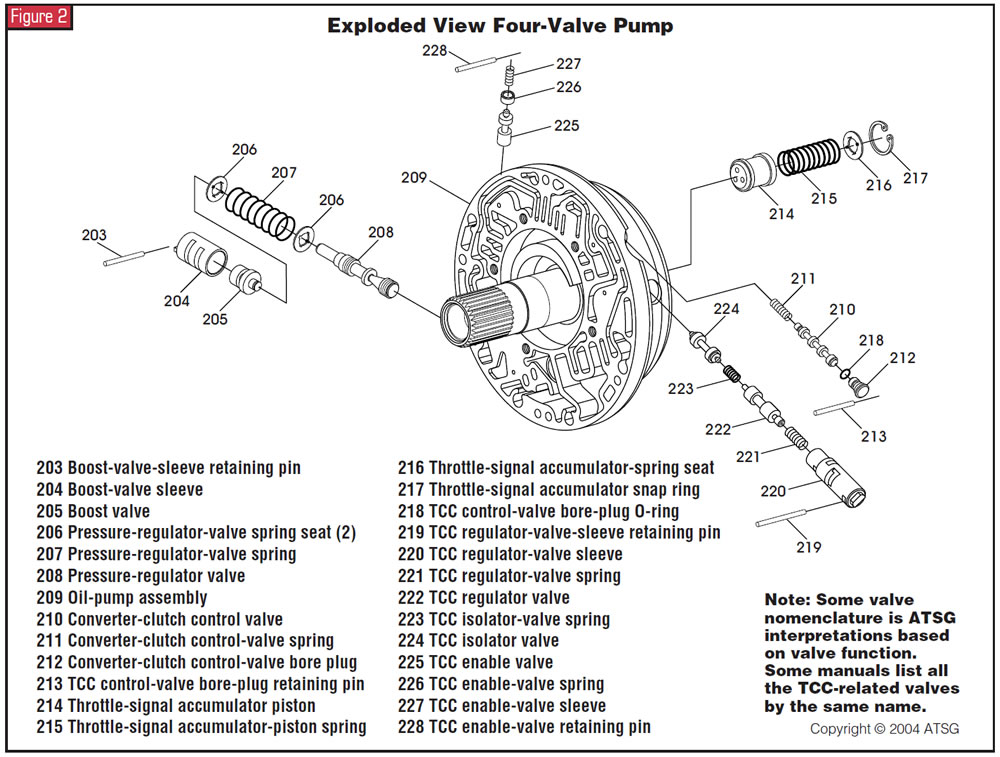

Parts change: In production for the 2000 model year, Isuzu Trooper and BMW models received the PWM TCC apply strategy. This created the need for a PWM solenoid, which happens to be the same as the 4L80-E PWM solenoid (see Figure 1). This, of course, changed the internal wiring harness because of the connector change. The pump changed from having two valves to four valves. The additional valve trains are the torque-converter regulator valve and the torque-converter enable valve (see Figure 2). Special note: ATSG has named these two valves on the basis of valve function. If you happen to find a factory manual that names them something else, don’t be confused. The torque-converter control valve also changed and now has a bore plug with an O-ring. The pump plate and bellhousing also changed because of the valve additions, and, of course the TCC went to a high-carbon or woven type.

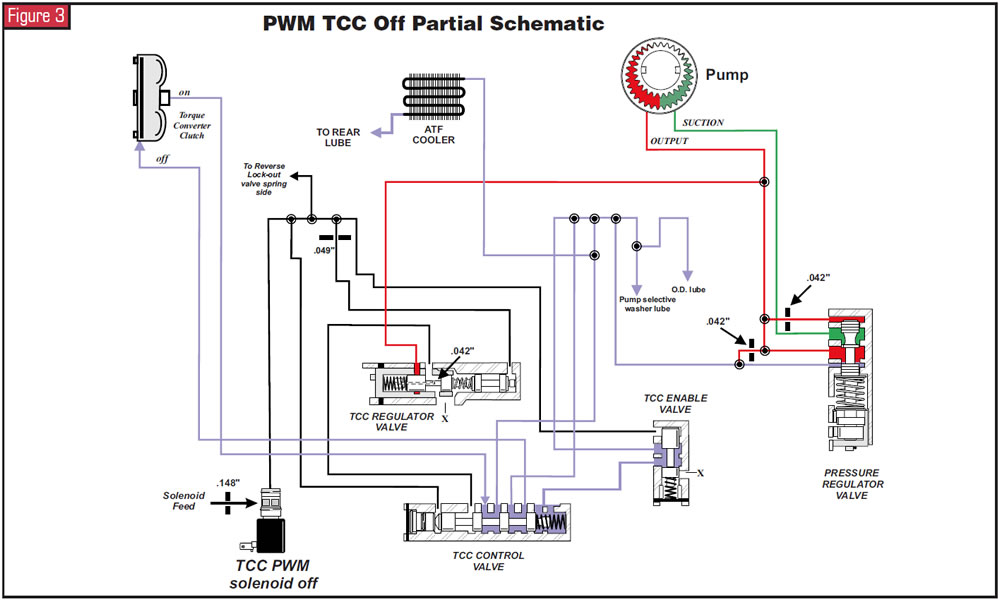

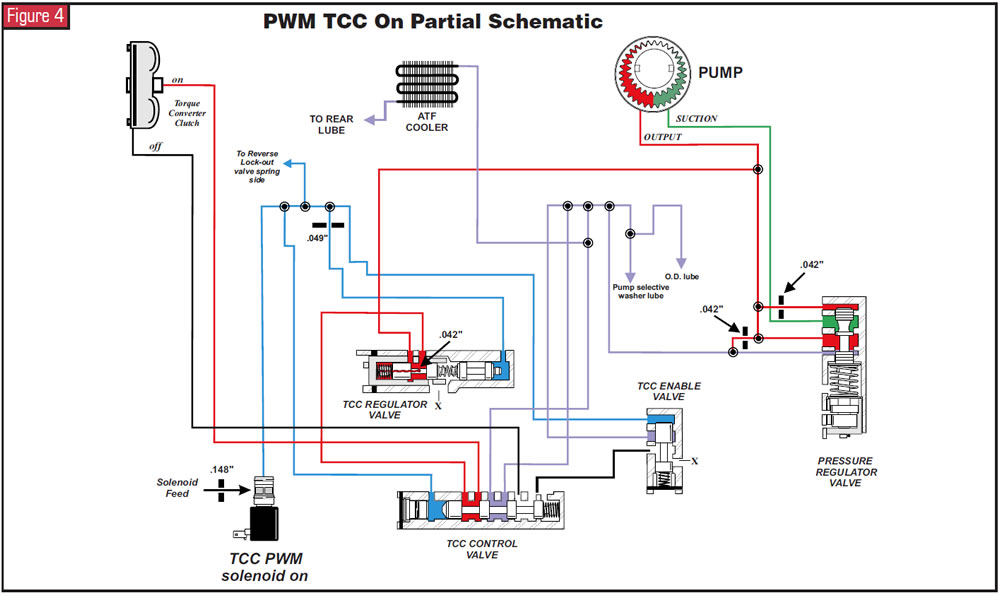

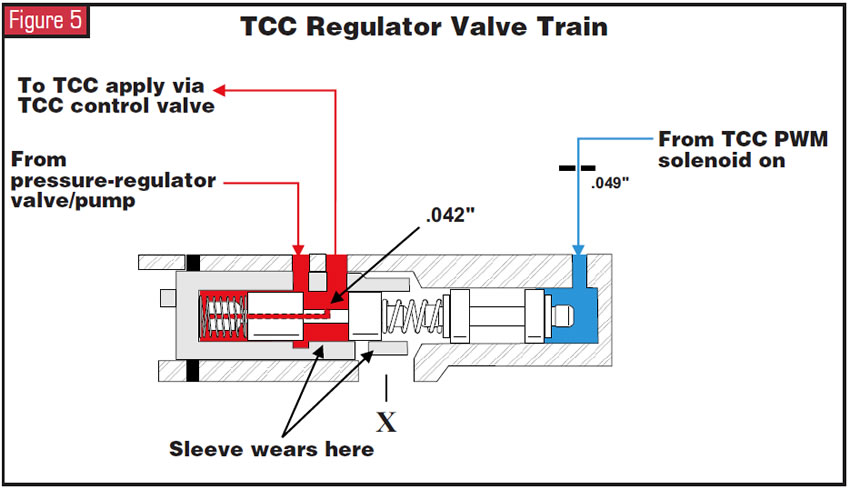

The point: The main focus of this article is to show how it works. No known hydraulic-circuit diagrams have been available for the PWM TCC apply, so I decided to fix that. Refer to Figure 3 for a partial hydraulic-circuit diagram of the TCC off. Figure 4 shows a partial schematic of the TCC when it is on. Notice that the PWM solenoid, when it is on, is in charge of stroking three valves simultaneously: the TCC control valve, which basically is the switch valve; the TCC enable valve, which controls the spring side of the TCC control valve and the exhaust path for TCC release oil; and the TCC regulator valve, through a 0.049-inch orifice in the pump plate, which controls TCC apply pressure on the basis of the spring pressure, and the balance feed through a 0.042-inch orifice, from the middle of the two lands of the TCC regulator valve (see Figure 5).

This is the root cause of the P1870. The TCC regulator-valve sleeve is what wears (see Figure 5) and creates a loss of TCC apply pressure. The great part about this sleeve is that it is sold separately from the pump and is easily replaced during overhaul for less than the cost of a fast-food lunch! The Isuzu part number for the sleeve is 8-96018-472-0, and if the valve is scored the part number for it is 8-96018-518-0.

Now you know how it works, and ATSG recommends replacement of this sleeve on every overhaul. We hope to see you in the upcoming 2005 seminar, where we will cover this problem a little more in depth, showing and comparing all the on-off and PWM changes.

Thanks to some people who really helped make this information possible: Ted at Ted’s Transmission, Alex Biliski at Santilli’s Transmission, Dynamic Dino and John Forrester.