Torque Converter Tech Tips

- Author: Ed Lee

The 300mm converter has become very popular in GM units. First used in the Corvette and F-model vehicles (Firebirds and Camaros), today it is also used in most trucks, vans and SUVs. The converter is also manufactured in a 280mm version (VJCX, for example).

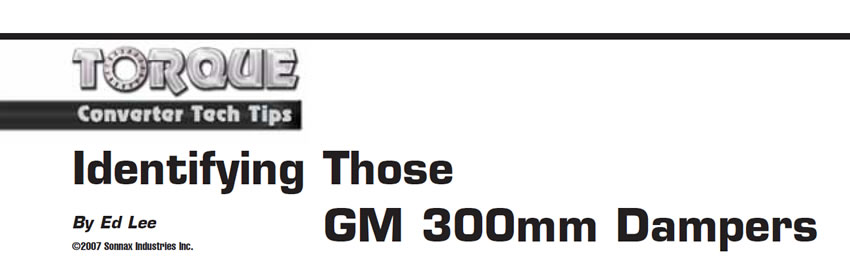

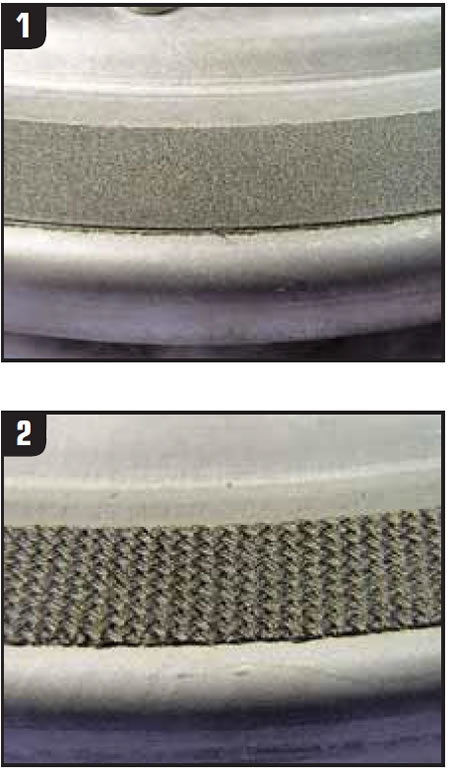

When the 300mm converters were used in only the Corvettes and F- cars, they had a “graphite-type” non-slip clutch lining (see Figure 1). This lining was porous in nature and helped the TCC-engagement feel. When the clutch-apply strategy evolved to the ECCC (Electronically Controlled Clutch Capacity) strategy, the lining was upgraded to woven carbon (see Figure 2). The graphite-type lining was never used in 300mm converters in truck applications. In the truck applications, the lining started off as woven carbon, and that lining is still what’s used today.

The springs used in the dampers may be a bit confusing, because the dampers can have as many as 12 springs or as few as four. When the 300mm-style converters were first introduced, they had two possible dampers available. The damper used in V-8 applications had a six-pocket design and a full set of 12 springs, six inner and six outer (see Figure 3). The damper used for V-6 applications was a four-pocket design and used eight springs, four inner and four outer.

When GM started using ovate (oval) wire springs, the automaker discovered it was possible for a single spring coil with ovate wire to replace a conventional inner and outer set – an obvious cost savings. Eventually the ovate single-coil springs replaced all the inner and outer spring sets. During the time that the dampers were being transitioned from the conventional inner and outer spring sets to the ovate springs, many different combinations could be found. For instance, it was possible to find two sets of double springs and four single springs in the same damper (see Figure 4).

Since the single ovate spring has the same spring capacity as the conventional inner and outer set, they can be interchanged. The six-pocket damper has about 515 Newton-meters (Nm) (380 lb.-ft.) of capacity, whether it has 12 conventional springs or six ovate springs, and is used for the V-8 applications. The four-pocket damper has about 380 Nm (280 lb.-ft.) of torque capacity with either type of spring and is used for most V-6 applications.

As long as all the spring cavities (pockets) are being used, this is a good method of separating the V-8 from the V-6 dampers. This method works well on most 300mm converters; e.g., the TMAX, TMBX, TLBX and TLCX code converters. With the 280mm converters, you may find a few exceptions. For example, the VJCX code converter may be found with a six-pocket damper with only four pockets being used. In this case the damper should be treated as if it were a four-pocket damper and used in only V-6 applications (see Figure 5).

It is very important to have the correct damper springs for each application. If the damper springs are too heavy, the TCC-engagement feel will be firmer. This may turn out to be a drivability complaint.

The real problems are created when the damper springs are too weak. If the damper springs bottom out during torque reversal before the TCC releases, the release feel will be like a kick in the backside.

In summary, don’t rely on converter codes to identify a 300mm-converter damper. Counting the number of spring pockets is the best method of separating the dampers – provided the spring pockets are being used. Also remember that the graphite-type lining (which looks like most aftermarket high-carbon) was used for only early Corvettes and F-cars. Most ECCC applications will use the woven-carbon lining.

FYI: Performance-engine builders have been using ovate-wire valve springs for years. Ovate springs also are being used in the accumulators of some late-model 4L60-E transmissions.

For most converter shops, trying to identify 300mm dampers previously was like being placed into a barrel and being told to stand in the corner. Hope this information makes identifying the 300mm dampers a little easier.

Ed Lee is a Sonnax Technical Specialist who writes on issues of interest to torque-converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com. ©2007 Sonnax Industries Inc.