Up to Standards

- Author: Mike Weinberg, Contributing Editor

In 1993 BorgWarner introduced the T56 six-speed manual transmission for the GM F-body cars (Camaro/Firebird). This unit featured six forward speeds with 5th and 6th being overdriven. Tremec bought the standard-shift division from BorgWarner and continued to refine and develop what is arguably the best six-speed design for the money.

The T56 now is found in Camaros, Firebirds, Dodge Vipers, C5 Corvettes, Aston Martins, the Australian Holden, Mustang Cobra R’s, the new Pontiac GTO and the just-released Cadillac CTS-V. Tremec also developed an aftermarket T56 unit that replaces the T5 units used in earlier Mustangs, Camaros and Firebirds. This unit is a direct bolt-in, which will require some modification to the cross member, driveshaft and, on Mustangs, the exhaust system.

The T56 is also a great choice for many hot-rod and kit-car enthusiasts because of its high torque rating, extremely smooth shifting, ease of installation and readily available, reasonably priced parts supply.

The T56 weighs about 125 pounds and has a torque rating of 450 lb-ft. We have routinely exceeded this torque rating in many applications. We have installed T56 units in late-model Impala Super Sports equipped with LS1 engines and twin turbos by Gale Banks. These are heavy cars producing more than 850 horsepower and at least 700 lb-ft. of torque, with no transmission problems.

The secret to exceeding the torque specs is to make sure that the tires become the safety valve. If you can generate wheel spin, you save the transmission and driveline components from torsional damage. In applications such as pro-class drag racing, it will be necessary to upgrade the transmission components to heavier-duty pieces, but that will be discussed later.

The T56 is available in a variety of ratios, but the two most common follow:

LS1 (MM6) ratios

- 2.66-1 1st gear

- 1.78-1 2nd gear

- 1.30-1 3rd gear

- 1.00-1 4th gear

- 0.74-1 5th gear

- 0.50-1 6th gear

LS6 (MM12) ratios

- 2.97-1 1st Gear

- 2.07-1 2nd gear

- 1.43-1 3rd gear

- 1.00-1 4th gear

- 0.80-1 5th gear

- 0.62-1 6th gear

With 5th and 6th being overdriven, we have the best of both worlds. At highway cruise speeds in 5th, engine speed is about 2,000 rpm at 60 mph. In truth, the sixth speed is basically unusable for top end with street vehicles. You would need about 800 horsepower to have decent acceleration in 6th, but it makes for a really fuel-saving cruising gear and it offers people with radically cammed engines two usable highway gears so you can drive without the valves going through the hood.

Other design features of the T56 include very advanced synchronizer technology that uses double-coned and triple-coned synchronizers for very smooth shifting under high torque loads. The cases are aluminum for enhanced weight savings. Tapered roller bearings support the mainshaft and countershaft, and all speed gears ride on needle roller bearings, which cut parasitic drag losses, improve shifting and support high-speed performance.

The reverse idler gear is in constant mesh, which reduces shift effort and noise when you engage reverse. The shift forks are on a single rail internally mounted in the transmission, with multiple shifter locations possible. The clutch adapter plate is integral and increases the strength of the unit in response to high torque loading.

Updates for the T56

With such a wide variety of vehicles using the T56, you will see more and more of these units for repair. Whenever you work on one, use these updates to give your customer a value-added, great-shifting transmission.

1 – The 3-4 stock shift fork is aluminum. You will find that the shift rail will begin to enlarge the bore in the fork and cause it to have radial play. Always test the fork by placing on the rail and seeing whether it rocks front to back. This will cause shift problems 3-4 and gear jump-out in 3rd and 4th. You can bulletproof the unit by replacing the aluminum fork with a steel 3-4 fork, part # TNEC-0843, and end all those concerns.

2 – The earlier-design synchro rings were paper lined, similar to those in the T5. Discard those rings and upgrade the unit to the latest-design carbon-fiber synchro rings. This will improve shifting and durability.

3 – These units will invariably be used at high speeds because of the vehicles they are in and the human “need for speed.” At high speeds in many applications, the driveshaft will begin to whip and put a side load on the rear extension-housing bushing, which will cause the bushing to “walk” into the rear seal, causing a leak, and if left unattended the bushing will spin in the extension housing and ruin it. Install the aftermarket silicone bronze no-walk bushing, part # T56-NWB, and make sure to balance and align the driveshaft.

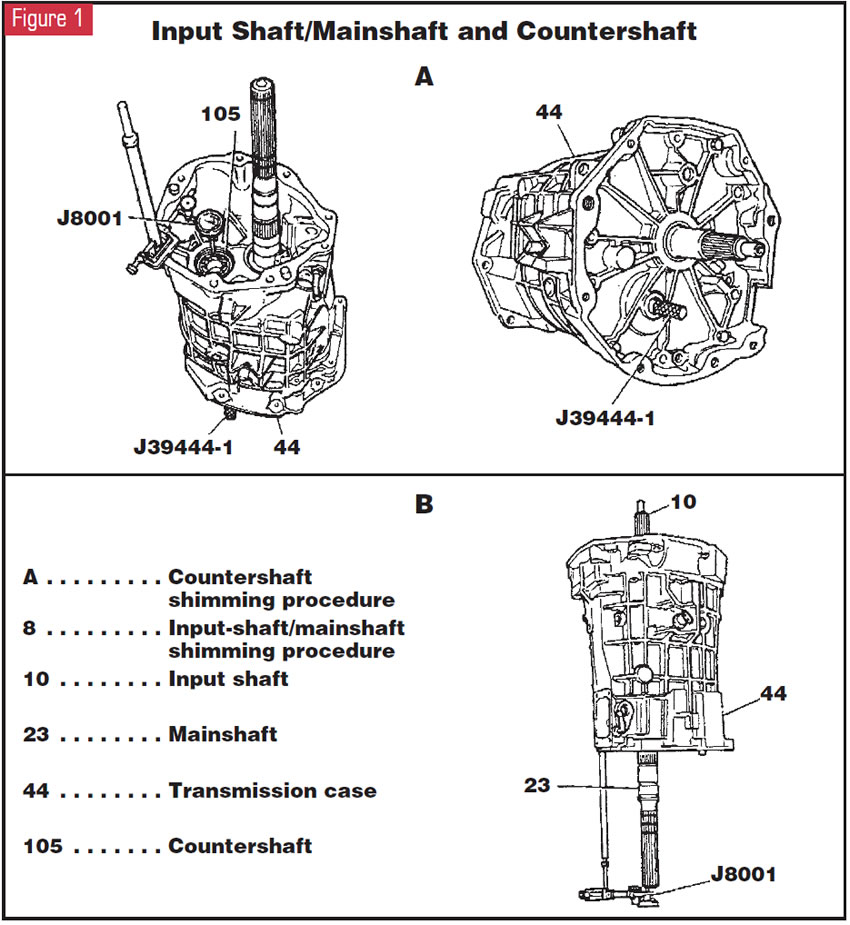

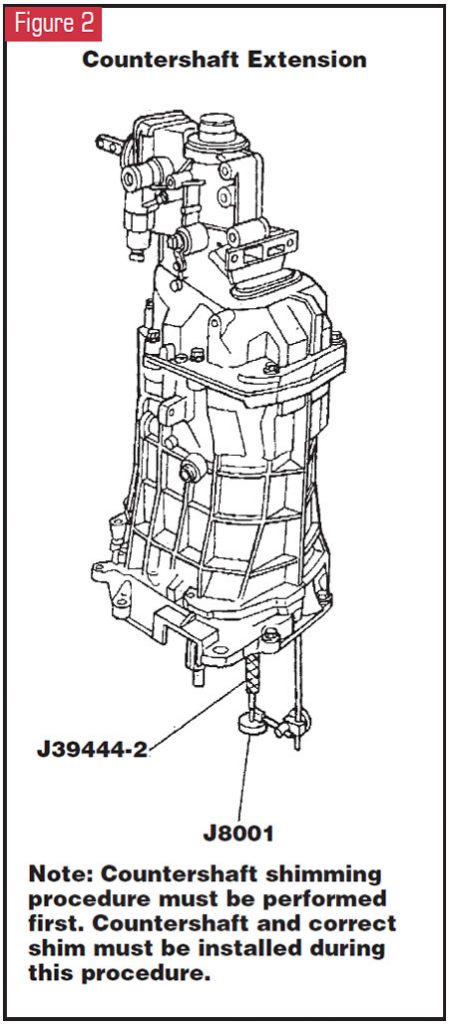

4 – Shimming these units correctly is critical to quiet, long-lasting operation. The factory specifications are 0-0.002 in. on the input shaft, countershaft, mainshaft and auxiliary shaft. Make sure you shim these units to zero endplay with zero preload. There should be no free play in the shafts, but they should turn without any resistance.

As the unit heats up and the cases expand you will have slightly more endplay. If you start at zero, the unit will remain quiet. If you start on the loose side of the spec, you will wind up with noises at speed and a short-lived unit.

Common Problems

These units are in vehicles that are driven hard by their owners. what is the use of having something that you don’t try out once in a while?

1 – Jump out or grinding in reverse. This usually is caused by driver error. We know that in today’s busy society, no one waits for the clutch to spin down before engaging reverse. The T56 has a further issue to be discussed with the customer, and that is the 4-5 shift. In their haste to make that lightning shift from 4th to 5th (really impresses your girlfriend and any troopers who are watching), it is common to travel too far right with the shift lever and get to reverse. This will be accompanied by a slight ratcheting noise as the front of the reverse-gear engagement teeth go from good metal to powder.

It takes only one or two of these missed shifts to finish off the reverse-gear engagement teeth. Shifting to reverse now becomes notchy and the unit may pop out of reverse. Make sure your customer is aware of this problem and uses reasonable care.

2 – Many internal problems are created by external sources. It is critical that you make sure these vehicles have a perfectly adjusted clutch release. The drivers invariably will rush their upshifts and downshifts. If they move the shift lever into the gear selected before the clutch has had time to spin down and release, there will be extreme wear to the synchronizer rings and components. The common effect of this is to break the 3-4 synchro keys and have the unit locked in 3rd or 4th. Another symptom of this kind of abuse is that the fork pads will be spread or wiped out. These are clear indications that the customer is speed-shifting (shifting without the clutch) or shifting too quickly for the clutch to release (short-throw aftermarket shifters compound this) or that the clutch components and hydraulics are worn or improperly adjusted. Save yourself some grief and be up front with the customer as to these problems. After you have completed a repair on any stick-shift vehicle it’s always smart to take the customer on a test drive. You drive and then let the owner drive and note his habits, capabilities and experience. Some gentle suggestions on how to prolong the life of his transmission are usually welcome, and now he knows that you know.

3 – Cracked or broken splines on the auxiliary countershaft generally are caused by the unit being shimmed too loosely on the main and auxiliary shafts. 5th and 6th speed gears are mounted on their own separate countershaft, which is called the auxiliary shaft. On unit assembly, you first shim the mainshaft and countershaft correctly, and then after the mid-case is installed, you must shim the auxiliary shaft to zero endplay and zero preload. Failure to do so will cause noise problems in 5th and 6th, as well as spline damage to the auxiliary shaft.

Another source of early spline failure to the auxiliary shaft is driver error – shifting to 5th at a very low road speed and lugging the engine, which beats up the transmission components.

4 – High-speed noise or vibration that usually occurs over 80 mph is caused by driveshaft defects. I don’t advocate your road-testing vehicles above the legal limits, but you know if you drive on the highways that all the customers do. We have had customers who complain about driveline vibrations at 120 mph. If the unit is shimmed correctly, this will always be a driveline or suspension problem.

The T56 is a great design and a profit center for any shop. My company, Rockland Standard Gear, provides these units in about a dozen variations for street, performance, road racing and drag racing. You can increase your business by becoming the local T56 expert and doing business with customers who have money and want to spend it on enhancing vehicle performance.

To look at the possibilities for your shop, go to www.rsgear.com and look at the “performance units” section. You also will find all the T56 specs and installation guides under the Tremec section. In the current repair market you need to be proactive and find new ways to bring in the business that is now evaporating to new-car sales and leasing.