Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: 6R140

- Issue: Keeping up with upgrades

Not a ton but there are some, so be ready

The transmission workhorse of the Ford family was developed internally to rival other manufacturer’s heavy-duty gearboxes such as the Allison 1000.

Unlike the 6R60 / 6R80 models that were a carryover from the ZF6HP26, Ford started with a clean sheet of paper in the development of the 6R140. To say that this unit is a beast would be an understatement due to the fact that it weighs more than 300 pounds.

The overall layout of the 6R140 probably has more in common with the GM 6L80 than the Ford 6R80, especially at the front end of the unit due to the forward/direct clutch assembly design. Both clutch packs are contained within one housing. The 6R140 low-reverse clutch assembly differs from the 6R80 and 6L80 since the piston is positioned in the back of the case, not the back of the center support. The 6R140 also had an OWC (one way clutch) from the get-go, unlike the 6R80, which did not initially but did later on. At least the valve body is not a mechatronic (TEHCM) design, although there is solenoid strategy that must be addressed whenever certain repairs are made, such as replacement of the transmission, valve body or individual solenoids.

As with other transmission families, the 6R140 has several variations including with and without PTO, gas or diesel engine, standard and commercial usage and 2WD or 4WD applications. All of those options resulted in a fair amount of different replacement components initially, although upgrades were not bad when comparing them to another model such as the 5R110W. As they say though, time marches on.

The pendulum really started to swing in July 2016 in preparation for the 2017 models. As in the past with other transmissions most component upgrades were no-brainers, although there were some that made little sense.

Rear planetary: One 6R140 component upgrade in 2016 that may be of a questionable need has to do with the interface of the center support and rear planetary carrier. When the 6R140 was launched in 2010, Ford apparently decided that the rear planetary needed added support due to either weight or load concerns; therefore, a support plate was added to the front of the planet that served as an outer bearing race (Figure 1). The bearing itself was pressed onto a lip at the back of the center support (intermediate clutch housing). The planet carrier in effect was supported at the front by the center support bearing and at the back by the overdrive clutch hub/shaft. That design has now changed.

For some reason Ford has decided that the planetary needs no support at the front other than the mechanical diode and has therefore omitted the support plate (Figure 2). Currently, this upgrade (or downgrade) only applies to the standard duty six gear planets, not the commercial duty eight gear planets. The mechanical diode was also modified somewhat on the new design carrier.

The catalog description of this new planetary refers to it as a kit although the contents only include the planet and instruction sheet. The instruction sheet is a bit vague as to why this was done, when the changes occurred and gives the impression that there is a second design support plate. The new design planetary does not contain any bolt holes that would be needed to attach a support plate either. The OE part number for the updated six-gear standard duty planet is HC3Z-7D006-C. The eight-gear commercial duty planetary part number is FC4Z-7D006B.

Center support: The other part of this equation is the center support, which will differ between gas and diesel applications due to the intermediate clutch quantity. The lip at the back of the center support is where the planetary bearing is pressed onto (Figure 3). The center support is positioned directly in front of the planetary mechanical diode outer race and is held there by a big mutant snap ring which is fun to deal with. In addition to the planetary bearing interface issue is another wrinkle.

The center support also got a facelift either due to the planetary upgrade or an issue with the support itself but regardless there are now more part numbers to deal with. Apparently, Ford felt that there is a substantial fretting issue where the support contacts the mechanical diode similar to what occurred on the GM Turbo 400 decades ago where the center support wore into the case and was modified accordingly. The 6R140 center support overall width has been reduced to accommodate a steel ring (Figure 4). The anti-fretting ring is the diameter of the center support and is sandwiched between the mechanical diode (Figure 5). The thickness of the ring is approximately 0.037”. The width of the previous design center support is 3.106” whereas the modified support width is 3.076”. Currently the ring is not available separately.

There are four different center-support part numbers available based upon being gas or diesel and year break. Up to July 2016 the gas application part number is FC3Z-7A130-C and the diesel application number is FC3Z-7A130-D. Beyond July 2016 the gas part number is FC3Z-7A130-F with the diesel part number of FC3Z-7A130-G. The upgrade package contains not only the center support and steel ring, but it also contains new intermediate clutch frictions. As with the instruction sheet from the planetary kit, there is an instruction sheet included with the center support as well and does contain a little more information than the planetary version. Differences between supports are minimal.

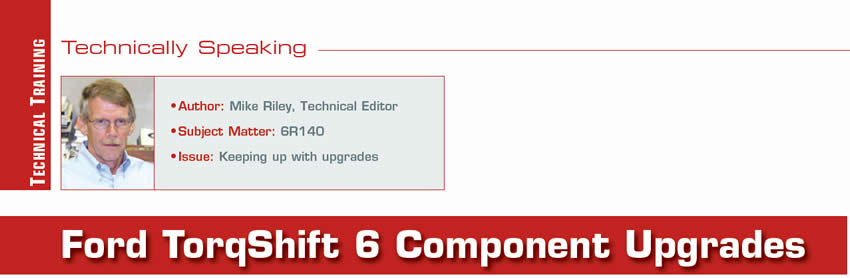

Intermediate frictions: Speaking of intermediate frictions, there are now several to choose from. When the 6R140 was first released Ford found it necessary to provide different friction material based upon whether the unit was used in a gas or diesel application. An easy way to tell the difference is by color (Figure 6). The brown friction plate on the left is for gas and the gray material plate on the right is for diesel. Initially both friction plates were 0.085” thick, at least up to March 2014. At that point a change was made mainly affecting the thickness which was reduced to 0.065”. The diesel applications are considered high-energy material but anyone can pick their poison. The early thick gas friction part number is BC3Z-7B164-G and the late thin gas part number is FC3Z-7B164-B. The early thick diesel friction number is BC3Z-7B164-C and the late thin diesel part number is FC3Z-7B164-A.

All intermediate frictions currently are the full wafer design. That is not the case with the forward or low-reverse frictions which started out as full wafer but has since been changed to the segmented design as is the case with many other applications (Figure 7). The segmented (button) frictions will retro.

Front planetary: Since the 6R140 was launched there have been several front planetary carrier part numbers although a couple have been trimmed. Regardless, there are still several flavors to choose from ranging from a three-gear up to a six-gear design planet with the six-gear type being released in July 2014. One version that does not appear in catalog information is a five-gear carrier (Figure 8). If needed, the six-gear carrier is part number CC4Z-7A398-A and is not too costly.

Valve body separator plates: As expected there have been changes to the valve body including the castings. Two significant changes involve a two checkball valve body versus a three check ball body as well as changes that occurred in March 2014. Always use caution when replacing any component of the valve body in order to avoid problems. Currently, there are four different separator plates available and are listed primarily by month and year break. As with many other newer transmissions, the separator plate has gaskets bonded to it (Figure 9). All four separator plates have a production part number stamped into them that should be compared with the original plate. The original stamp number, however, may not be identical to the replacement so always compare all oil holes. The service part numbers and month / year breaks currently available are:

BC3Z-7Z 490-D (2010-3/2012) BC3Z-7Z490-E (3/2012-10/2012)

BC3Z-7Z490-F (10/2012-3/2014) FC3Z-7Z490-C (3/2014-UP)

Note: Refer to the ATSG 2015 technical manual for detailed hydraulic schematics and illustrations.

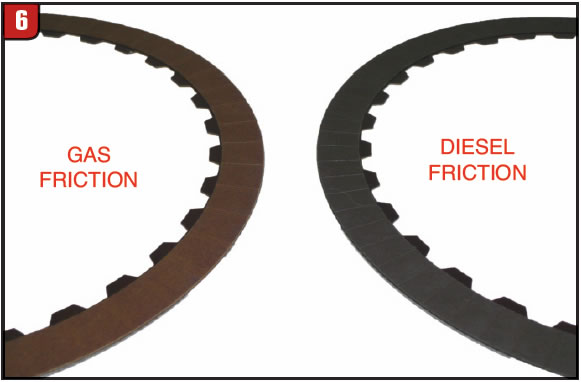

Pump assembly: The 6R140 uses two basic pump designs, with or without PTO. The configuration between both designs are the same with the main difference being whether or not the pump contains a PTO drive gear (Figure 10A). The PTO design pump is more costly due to the additional gear and lower volume used in the field. There has been several part number updates over the years with the current numbers being HC3Z-7A103-A for non-PTO applications and HC3Z-7A103-B for PTO applications.

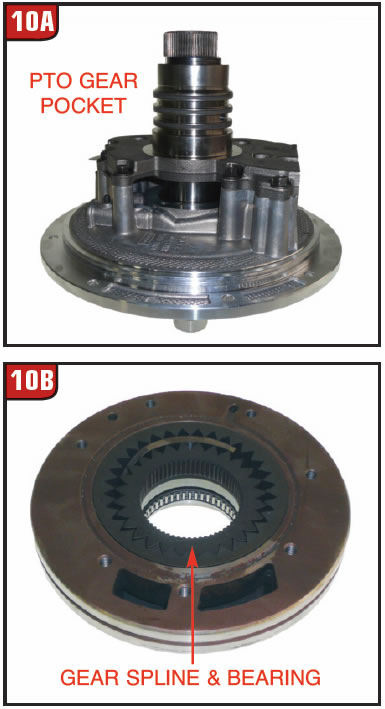

The 6R140 is rather unique in that the pump body uses a bearing for the converter hub instead of a bushing, the pump drive gear has splines like a Honda and the torque converter metal-clad seal is a special design as to how it seals to the converter hub (Figure 10B). Not only does the torque converter hub have splines around the OD, but it also has splines on the ID to accommodate the PTO gear.

The new design pump assemblies not only have changes in the castings for different reasons including reducing potential cross leaks, but there was a rubber check valve added to the converter seal drain back hole to keep the oil cavity charged. The new part numbers will retro.

There have been changes to other components for the 6R140 resulting in new part numbers although the actual changes are relatively subtle and most will retro back to 2010; however, it always pays to check.