Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Ford 6R60/80

- Vehicle Applications: Verify the specific application

In comparison, it could be worse

Part 1 of 2

Ford released the “kissin’ cousin” to the ZF6HP26 a decade ago and like the 6HP, changes have certainly occurred to the 6R60 family of transmissions during that time. Although as part of the agreement with ZF, Ford did use the actual 6HP for a short time, but the game plan from the start was to produce a home-grown unit, which Ford did in 2006.

The 6R60 was the first model to be produced, followed by the 6R75 and ultimately the 6R80, in order to address increasing torque commands. The 6R60 did have a fairly decent run, as transmission models go but, the 6R80 became the big winner with the 6R75 being merely a blip on the sonar screen.

As upgrades and modifications go, the earlier model transmission changes were not too brutal although as time went on the pace started to pick up noticeably. Model differences aside, component spit shining started to accelerate in 2010 resulting in a steady stream of upgrades well into 2014 and 2015. It is important to verify the specific application in order to receive the correct part during a repair.

Aside from actual changes to certain components is the issue of the part number itself, which in certain cases could actually flip-flop back-and-forth between year breaks, ending up with a part number that the component started out with. Beyond that, certain component changes are almost indistinguishable from the previous design and are interchangeable. Such is not the case with other items.

Pump: Initially, there were subtle changes to the 6R60/6R75 pumps that did not amount to much, although there were some part-number supersessions to contend with. The big change came about with the launch of the 6R80 due to a change with the input shaft and TCC feed. The easiest way to distinguish between the two designs is that the 6R60/6R75 stator support has a front bushing, whereas the 6R80 does not and the 6R80 bore is larger.

The 6R pump is somewhat different from other transmissions, in that, instead of a simple pump body and cover, the 6R has a small cast-iron pump body, an aluminum pump cover and an intermediate plate that the stator shaft bolts into. The original Ford service part number for the 6R60 was 6L2Z–7A103AA, which was later superseded to 6L2Z–7A103C. The original part number for the 6R80 pump was 9L3Z–7A103A; however, Ford decided to make a couple of design changes that impacts only the 6R80.

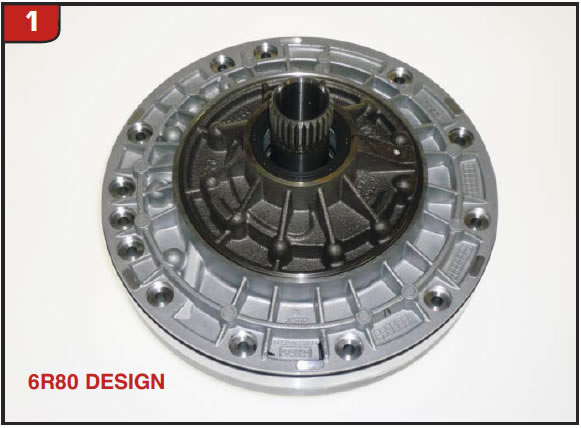

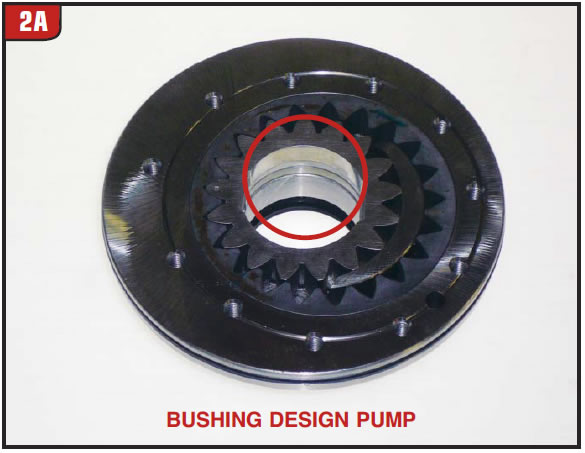

A new replacement pump for the 6R80 is OE part number BL3Z-7A103B, which services models up to March 31, 2014 (Figure 1). Another new part number had been released for April 1, 2014-up models and is OE part number FL3Z-7A103A. There is little difference when comparing the aluminum castings from the original 6R80 pump to the newer versions. The main difference between the 2014 applications has to do with the pump body and gears. Unlike previous models of 6R60/6R80 pumps that used a caged bearing to ride against the torque converter hub, both of the newer applications use a pump-body bushing (Figure 2A). Previous design pumps were only available as complete assemblies; whereas the upgraded designs are now also available as the pump body only under part numbers BL3Z-7A104-A and FL3Z-7A104-C respectively.

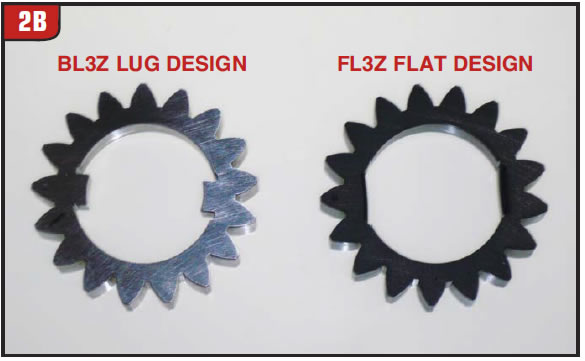

The modification of the pump gears has to do with the pump-gear drivers. Ford followed the ZF lead initially, meaning that the pump inner gear had drive lugs like GM or Chrysler, which was contrary to what Ford had normally done. That changed with the late 2014 pump gear, which now has flats instead of drive lugs, (Figure 2B). The new gears are now the same as the other Ford units.

Use caution when ordering the replacement pump so that it matches the torque-converter hub design.

Forward (A) clutch assembly: Although the forward clutch assembly has not been inundated with a ton of upgrades, there have been a few, mainly to handle torque-capacity variations. One item with multiple options is the apply piston in order to accommodate clutch-pack quantities (Figure 3). The upside is a lower profile piston can be used to increase the plate count. The piston on the left of the illustration is for the 6R60 and is part number 9L2Z-7A262-A. The piston on the right will accommodate most 6R80 models and that part number is 9L3Z-7A262-A. For some reason Ford released another piston for use on a 2015 Mustang with a 2.3L and 3.7L engine under part number CK4Z-7A262-A. They just keep on coming.

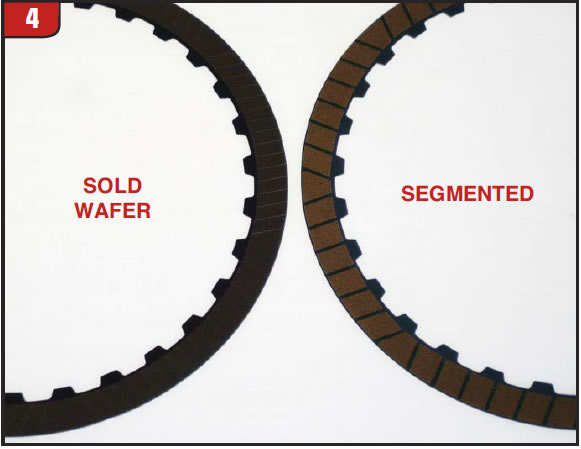

Friction-plate design has also been pretty stable, but there have been a couple of tweaks to be aware of. The first design friction was a common looking tan plate and the OE part number is 6L2Z-7B164-AA. Later on a minor change was made, which was not visible and that plate number is AL3Z-7B164-C. Following the trend of many other friction plates, the forward friction design was changed to the segmented (button) type in 2015 (Figure 4). The new forward friction part number is CK4Z-7B164-A.

Another item that involves the forward clutch assembly has to do with the connection to the input planet carrier. Due to the Lepelletier design, the input planetary carrier is anchored to the forward clutch housing via the piston retainer. The original 6R60 retainer had three sets of splines that meshed with a three-gear planet. When the input planet was increased to a four-gear design, the retainer was changed accordingly (Figure 5). The retainer/planet set ups are interchangeable. The three-gear design retainer part number is 9L1Z-7H360-A, and the four-gear design is 9L3Z-7H360-B.

Direct (B) clutch assembly: As with the forward clutch, the direct clutch has not had a lot of changes either, although there have been a couple. As usual, what changes have been made are to address torque capacity, such as changes made to the apply piston (Figure 6). The aluminum piston part of the assembly is the same with only the steel apply ring being a different height. The piston on the left is part number 9L2Z-7A262-B and the shorter piston on the right is part number 9L3Z-7A262-C.

Another change, which is year- and model-dependent has to do with the steel plates. Steel-plate thickness does vary between clutch assemblies and traditionally there were two different thicknesses. At the beginning of 2010 another steel thickness was released under part number AL3Z-7B442-A (Figure 7). The new plate is 0.070” thick and can be used on any of the clutch packs.

Overdrive (E) clutch assembly: As stated, an easy way to distinguish a 6R60 from a 6R80 is by the pump stator support and input shaft design. To accommodate the stator support front bushing, the input shaft, which is made to the overdrive clutch drum, has a bushing journal (Figure 8). In addition, the 6R60 input has two sealing rings whereas the 6R80 has three. For some reason there was a design change to the 6R60 overdrive clutch drum/shaft and the cost is now twice that of the 6R80. The 6R60 OE part number is BL3Z-7F207-B and the much cheaper 6R80 assembly is part number 9L3Z-7F207-A.

One item associated with the overdrive clutch assembly that has had several part-number supersessions is the overdrive clutch hub. From the beginning the hub assembly consisted of a steel shaft with a stamped steel hub welded to it. Due to failure issues, that design was ultimately changed to a two-piece assembly that is held together by a snap ring (Figure 9).

The hub part is now made from real steel instead of beer cans and the new OE number is AL3Z-7F351-B. It is advisable to upgrade to this part and the cost is not too bad.

Center support assembly: A major departure from the original ZF cloned 6R60/6R80 transmissions occurred in 2011 and had to do with the addition of a one-way clutch, similar to the GM 6L80 models. The upgrade had an impact on several components starting with the center support (C/D clutch housing) and related items. Concerning the center support, one oil passage was removed affecting how the low-reverse clutch is applied (Figure 10). In addition, the cavity for the low-reverse piston is also noticeably different. First and second design assemblies are not interchangeable and are model dependent.

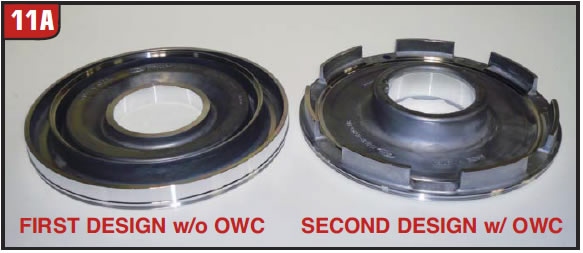

Although there are a couple of different intermediate (C’) clutch piston heights to accommodate torque capacity requirements, the big change occurred to the low-reverse piston on the backside of the support. The piston design was changed due to the addition of the OWC along with the return spring and retainer (Figure 11A). None of the components are interchangeable. As with the other clutch packs, another change was made to the low-reverse piston in 2015 to address the clutch-pack quantity in vehicles with smaller engines (Figure 11B). The previous non-OWC piston part number is AL3Z-7A262-B. The shorter new-design piston is OE number BL3Z-7A262-C and the taller piston is CK4Z-7A262-B.

To make room for the new OWC, an engineering feat was required in order to avoid lengthening the transmission overall. The type of OWC that Ford chose was the diode design and the outer portion of the diode contains windows to accommodate the low-reverse apply piston (Figure 12). To date, there is only one part number, which is BL3Z-7A089-L. Lastly, Ford started to change the low-reverse friction plate to the segmented design like the forward friction and based upon model will use the 0.070 thick steels.