Body of Evidence

- Subject: Finding the cause of converter-slip codes

- Unit: FNR5/4F27E

- Essential Reading: Rebuilder, R & R

- Author: Jeff Parlee

There are a couple of wear areas in the FNR5 and 4F27E that can cause converter-slip codes to set. Some of the factory trouble-code charts would lead you to believe that a solenoid was bad, because they send you to test the solenoid first. The best thing to do is to determine how the code is setting, and then you can determine where to look for the cause of the code.

As an example, let’s look at code P0741. Most times this code is defined as “torque converter clutch stuck off,” which is misleading. Stuck off, to some folks, means a bad TCC solenoid or a sticking TCC apply valve, and it could be. A better description, after reading about the code, would be “excessive TCC slippage detected.” The computer determines TCC slip by subtracting input-shaft speed from engine speed, and once the TCC slip exceeds a predetermined rpm the code sets. The code may not set the first time; the computer may need to see the failure more than once during an ignition cycle before it will set.

What can cause the torque-converter clutch to slip? Erratic speed sensors, TCC solenoid, worn TCC-valve bores in the valve body, a leak in the TCC-apply oil circuit, low line pressure or a glazed or burned converter clutch. More often than not, there is a leak in the TCC-apply oil circuit, usually at the rear pump-stator bushings. These two bushings have to support the turbine shaft, torque-converter turbine and forward-clutch drum. There is no support inside the front of the torque converter for the turbine shaft. The pump-stator bushings keep the shaft running true and seal TCC-apply oil from leaking to exhaust or release. These two bushings seal converter pressure and are used as sealing rings would be. The more these bushings leak, the lower the TCC-apply oil pressure. Keep in mind that a little wear on these bushings, which will cause a small loss of TCC-apply oil, becomes a much larger leak when the fluid is hot and thin.

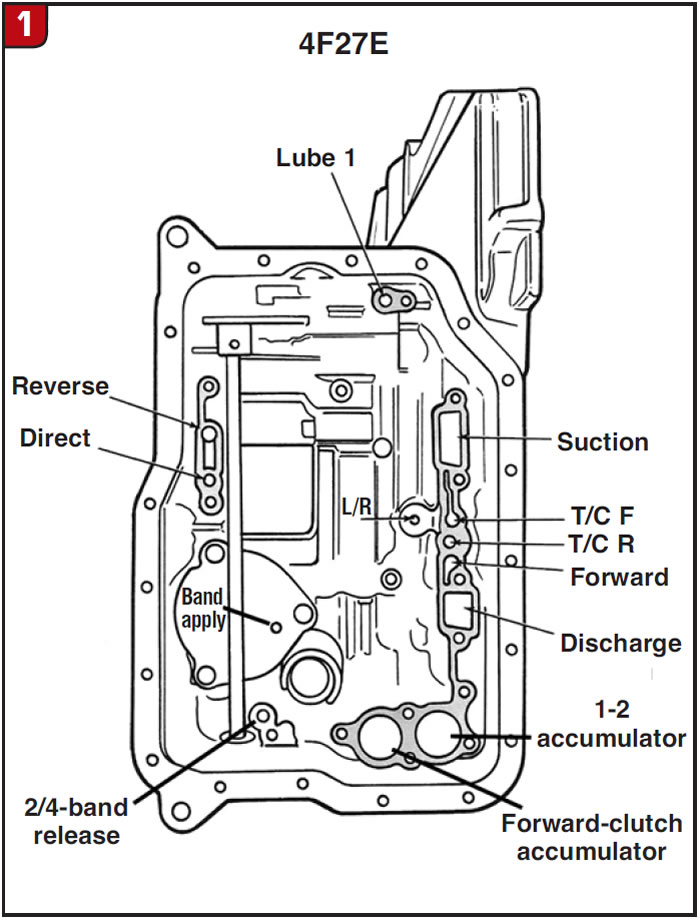

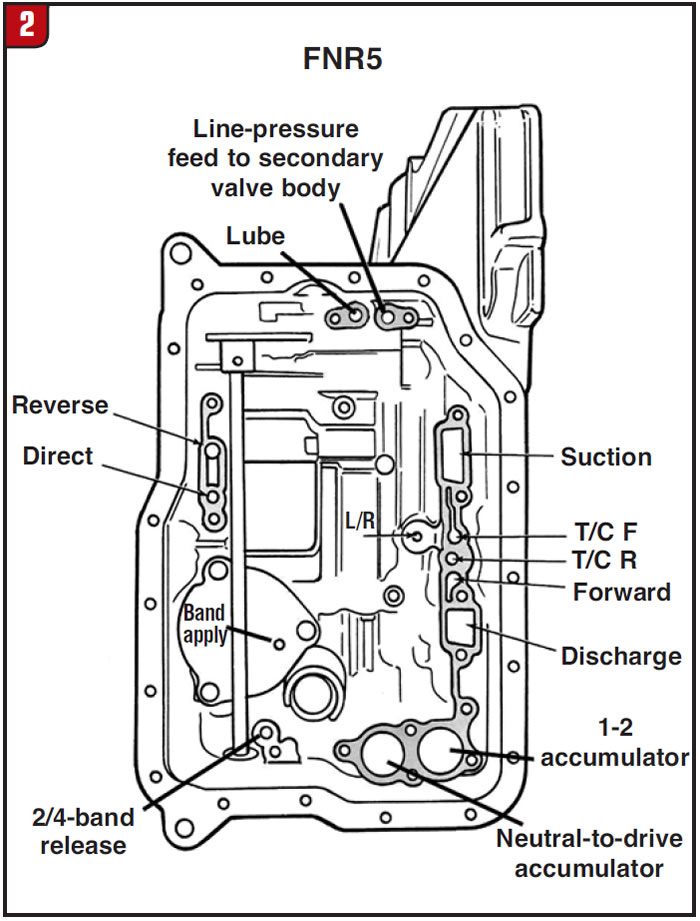

The TCC oil circuit can be air checked in the car by removing the valve body, blocking the T/C front passage on the case and blowing air into the T/C rear-case passage. The oil circuit should air check with no leaks, just like a good clutch-pack air check. Use caution when air checking a wet oil circuit; release the air pressure slowly to avoid getting sprayed with ATF. With the unit on the bench, you must install the torque converter and secure it in the bellhousing by bolting a wrench to the front of the bellhousing to hold the torque converter from moving. Squirt a generous amount of ATF into both the T/C front and T/C rear passages (figures 1 and 2) before performing the air test.

My suggestion would be to air check the TCC oil circuit after replacing the pump-stator bushings so that you know how the circuit should air check.

These bushings are a good thing to install on every overhaul to ensure that you have done the best job for your customer. The pump-stator bushings are made by several different manufacturers; check with your parts supplier.

Jeff Parlee is director of product support at ValveBody Xpress.