TASC Force Tips

- Author: Gregg Nader

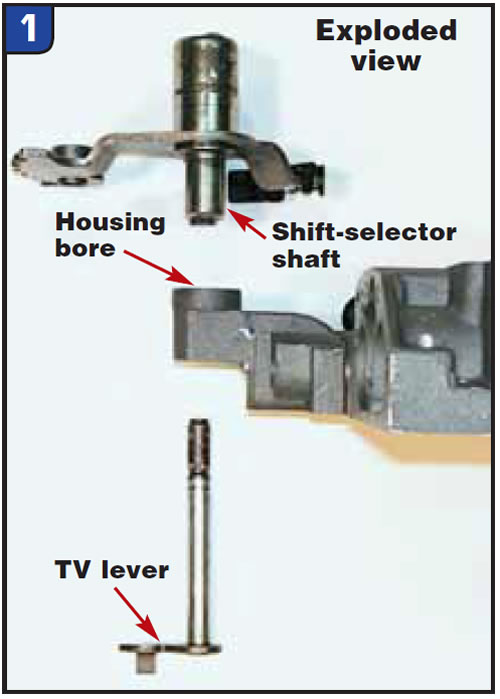

The basic design of the internal shift linkage of Chrysler/Dodge rear-wheel-drive transmissions has not changed since 1967 (Figure 1). As movement, vibration and wear take their toll over time, looseness of the internal linkage becomes a big problem. When there is excess movement in the manual lever, the manual valve is not held precisely in position, resulting in fluid leakage, cross leaks and unit failure. Even a small amount of positional error becomes a problem on these units, because of the narrow width of the lands in these Chrysler valve bodies.

There are established repairs available for where the internal shift linkage passes through the case and where the detent ball wears into its bore in the valve-body casting. Fixes for these two locations tighten the linkage, but the lower linkage pivot point in the valve body is one more area that wears.

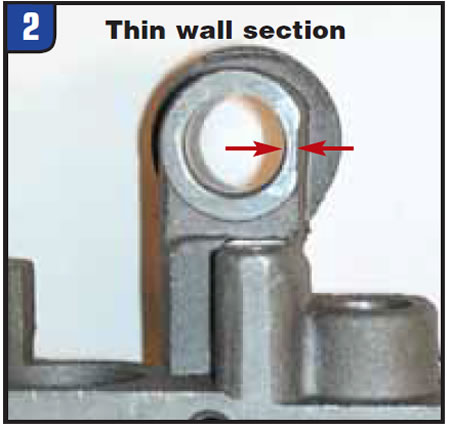

Shops have tried various approaches to repair the lower pivot, but typical bushings do not work well. The biggest problem is the flat on one side of the casting (Figure 2).

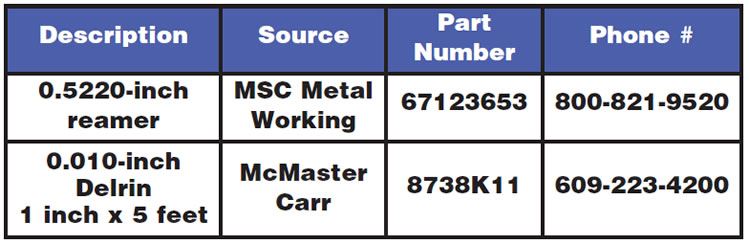

If the bore is machined oversize to accept a typical bushing, the wall thickness of the bore ends up too thin and the casting will crack. What follows is a method any shop can use: installing a very thin plastic Delrin® sleeve to salvage worn castings. Delrin is a high-strength, flexible, impact- and abrasion-resistant plastic material often used for bushings and thrust washers. The material used here is very reasonably priced. Items required for this repair include:

- A 0.522-inch reamer

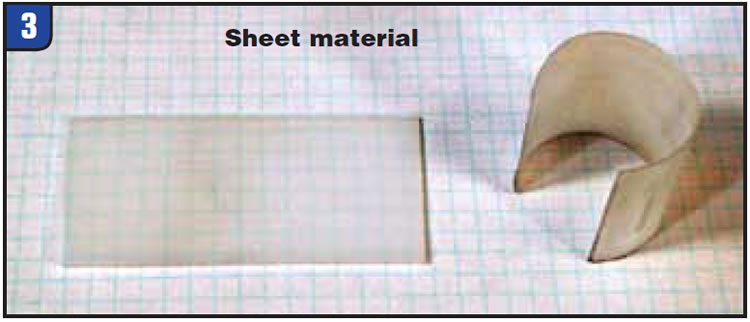

- Strips of 0.010-inch-thick Delrin shim stock

- An older linkage pivot with the lever portion removed

- A 5/16-inch-diameter x 8-inch-long steel rod

See the source list at end of this article.

Cut the 0.010-inch Delrin into small rectangles 0.730 x 1.5 inch as shown in Figure 3. The bore in the valve-body housing needs to be machined oversized to accept the plastic sleeve. There is a small unworn area in the bottom of the bore that can be used for centering. This process can be done in a mill, or even in a drill press. Figure 4 shows the reamer and the early splined/crimped-type internal linkage with the lever portion removed and attached to the 8-inch-long 5/16-O.D. steel rod with Loctite®. This will be used as an alignment pin to establish a centerline, prior to reaming.

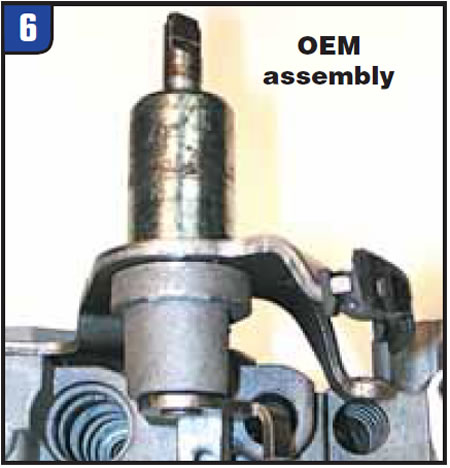

With the alignment pin in a chuck, clamp the casting in place in a drill press or mill so the pin is centered in the unworn portion of the bore. Replace the alignment pin with the reamer and machine the bore oversized. Roll the rectangle of Delrin into a cylinder and insert into the bore as shown in Figure 5. When installed, the plastic sleeve material is held captive at both ends: on the top by the shift-selector shaft and on the bottom by the TV lever (Figure 6).

The result is a wear-resistant thin-wall sleeve that corrects the looseness in this problem area. The repair restores the linkage to like-new condition, which will once more ensure precise positioning of the manual valve.

Gregg Nader is a Sonnax Technical Specialist and a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.