Tech to Tech

- Subject: Choosing the appropriate transmission repair

- Vehicle Application: 1998 Honda Accord

- Essential Reading: Diagnostician

- Author: Brian Manley

Deconstructing a transaxle raises a whole set of questions

When I was a young man, I attempted all eight ASE tests over the course of two test cycles. I passed all of the tests except A2 – Automatic Transmission and Transaxle. At that time, I simply did not have enough practical experience to pass the test; I mostly performed fluid and filter services and repaired and replaced complete units. It took a study guide and some study sessions before I earned that certification. I still do not get my hands into automatic-transmission fluid all that often.

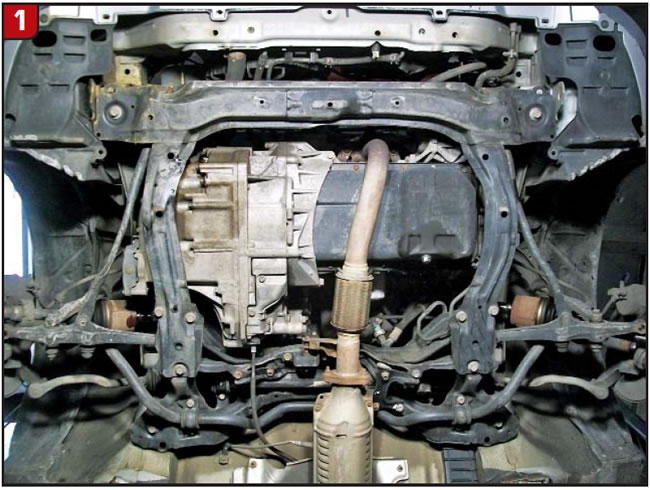

When a 1998 Honda Accord rolled into my shop with a customer concern of “poor shifting,” I thought a moment before saying “Yes.” I began with a fluid check and a test drive, finding that the shifting was indeed “poor.” I followed the test drive with a thorough visual inspection above and below the vehicle (Figure 1), and I wondered just how many possible causes could exist for this shifting issue.

The symptom was erratic upshifting. A scan of the powertrain control module (PCM) revealed Code P0758: Shift Solenoid “B,” so I confirmed the defective solenoid through its code chart, replaced the little rascal, and all was in harmony with my Honda. I felt proud that I could solve a shifting issue with an inexpensive external fix and wore my ASE “A2” certification with a bit more pride.

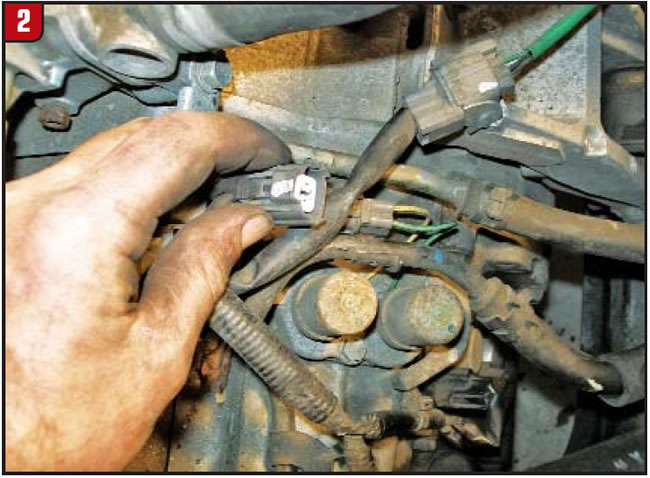

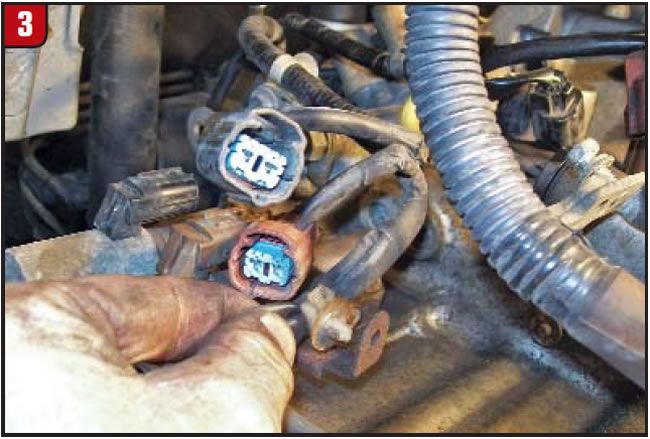

When the same customer returned a year later with a concern of “slipping between shifts,” I felt certain that this was going to be neither inexpensive nor external. After eliminating all external factors including trouble codes, fluid level and electronic controls, I determined that high mileage had simply worn out the internal clutch packs. Before eliminating any of the external solenoids as suspect, I individually energized them (figures 2 & 3) to see them function, and they all worked. So, now my customer needed a transaxle for a ’98 Honda Accord with 128,000 miles on the clock. My customer rightly asked, “Is it worth the money?”

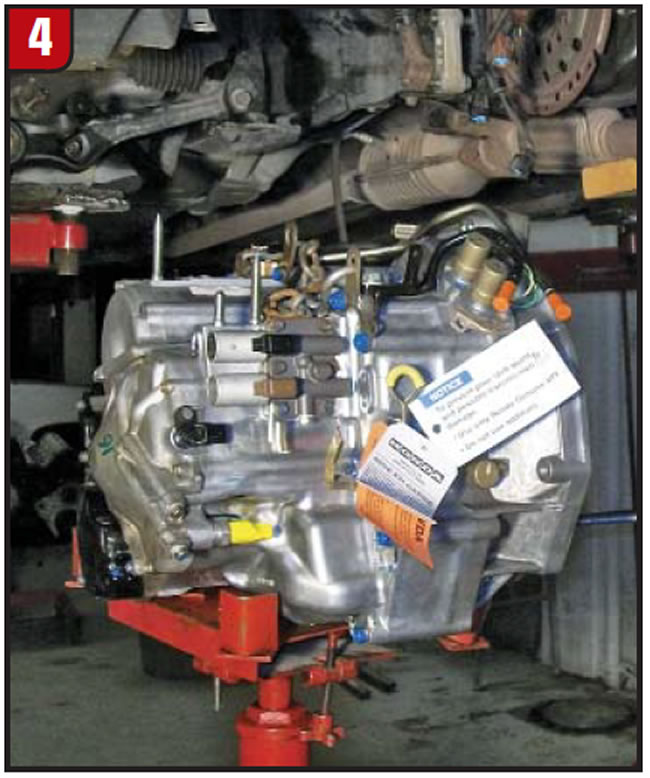

With a good transaxle, our Honda still had a value of around $5,000, so I performed a few Web searches and made a few phone calls. Used, lower-mileage transaxles would run around $1,000 – if we could find one. It quickly became apparent that there was a high demand for this unit. Remanufactured units range from $1,800 to $2,800, and these prices – combined with labor – gave my customer pause. My Honda parts specialist quoted me one of the best prices for a remanufactured unit. Ultimately, we decided that the remanufactured transaxle from Honda (Figure 4) would be the best choice for my customer, and he liked the warranty and the fact that it was a factory-remanufactured unit, with all of the updates. I felt good about this decision as well, and I was excited to install a factory unit! Am I a geek to enjoy picking up a remanufactured transaxle from Honda and spend time quizzing the parts manager while doing so? You betcha!

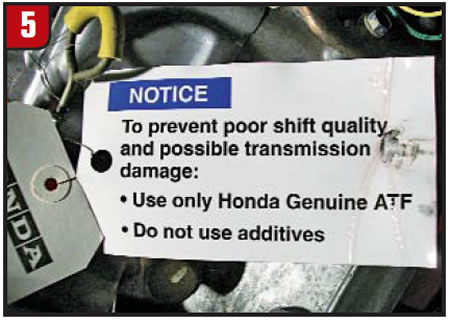

One important point about these Hondas is that the dealer parts manager – and every other credible source I know – insists that only the factory “Z-1” automatic-transmission fluid be used in these units (Figure 5). Beware of not heeding this advice and dumping in Dexron ATF that you may have on your shelf. A few technicians on iATN suggest that replacing the factory Z1 fluid with Dexron causes harsh shifting in these transaxles.

The other item of note is the inline filter kit that accompanies the factory rebuild. This was a slick install, including all of the brackets and gaskets that fit (Figure 6).

While I was discussing this unit with my Honda parts manager, he made me aware that this year had transaxles that had been “farmed out” and that since 2000 they had been produced by Honda again. These “farmer” units had such a high service rate that Honda issued Technical Service Bulletin 98-061, Automatic Transmission In-Warranty Program. Our Honda had surpassed the mileage limits to be eligible for replacement.

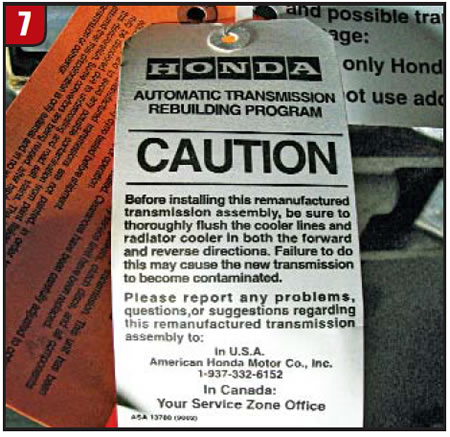

One critical issue to point out is: How many of us actually flush the transmission cooler and lines (Figure 7) after a transmission failure? The photo in Figure 6 begs another crucial question: Do you install an inline filter? I have installed many more air-conditioning filters than transmission filters, and I see the wisdom in doing both, especially if any metal could circulate into the new unit. Honda would not let its remanufactured unit go without this filter kit. In fact, it was necessary to ensure warranty coverage.

This is a difficult decision for our customers to make, and I am happy to have options to present to my customer that can keep his Honda dependable and on the road for years to come. Ultimately, we performed the transmission replacement – and my customer is pleased with my repair. However, I still find it tough to talk my customers into pulling the trigger on a repair like this, especially when the value of the vehicle is approaching “almost not worth it.”

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. He can be reached at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.