In having the privilege of presenting at Worldpac’s Supplier and Training Expo in Orlando Florida earlier this year, I met a couple of instructors from the Daytona State College who attended my seminar: Beau Bosman and Casey Knecht. During my presentation, I covered an issue with an Allison 1000/2000 that had the converter clutch cycling on and off. The crank sensor is mounted on the converter housing which receives its signal from the protrusions on the converter where the internal fins mount. One of these protrusions was flattened causing a loss of one pulse per each revolution of the converter. This consistent rhythmic pulse loss caused the computer to cycle the converter on and off. I then showed a picture of another converter where someone had decided to add a drain plug in between two of these protrusions. This caused an additional signal to be added to each revolution of the converter.

On this same topic, Beau shared with me an interesting problem he had with a vehicle he purchased. It was a 1999 Dodge Ram 1500 5.9L 4×4 with 283,000 miles. This is what he wrote:

I was able to buy the vehicle for $300 as it was about to go to the salvage yard to be laid to rest. The previous owner claimed the transmission had problems and so it sat for about a year before he decided to get rid of it.

Once the vehicle was towed to my garage, I charged the battery and started the vehicle. It idled fine in both park and all drive ranges. I then checked the transmission fluid, and it was found to be full and clean. Getting into the vehicle, when I raised the engine RPM to approximately 1200-1400 while in park, the vehicle started to misfire badly on multiple cylinders illuminating the check engine light.

A scan tool pulled code P1391 for an Intermittent Loss of CMP or CKP. No misfire codes were set.

When this misfire would take place, the tachometer would bounce wildly from the true 1200-1400 RPMs to not true RPMs of 3000 to 3500.

When it was driven, it continued to have misfires along with the tach bouncing from real to not real readings. Due to this misfire issue, excessive throttle angle was needed to get enough speed for the vehicle to make the 1-2 shift. The shift was then late and firm. As a result, it becomes near impossible to get into any higher gears. Thus, the transmission malfunction complaint from the previous owner.

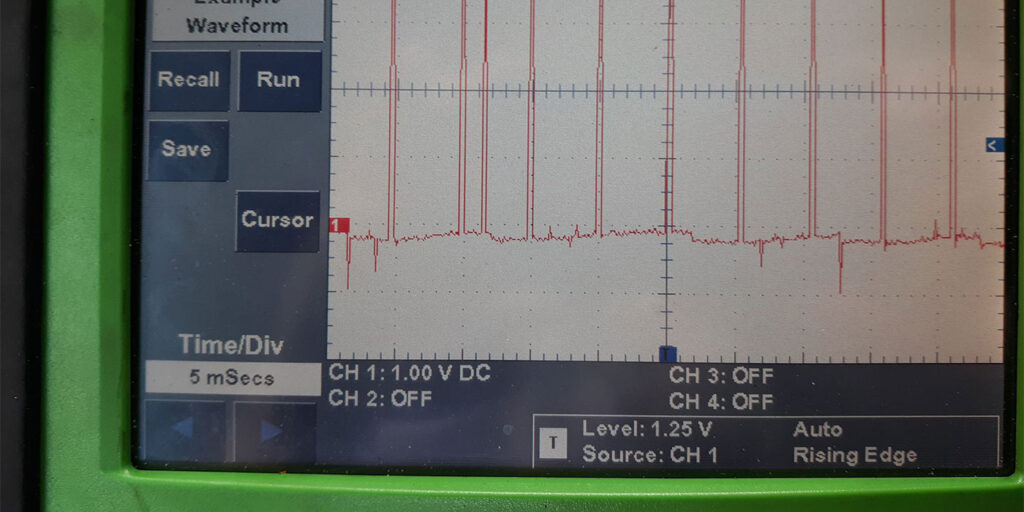

The code description suggests that the cam or crank sensor is dropping out, so I decided to use a lab scope to observe the signal.

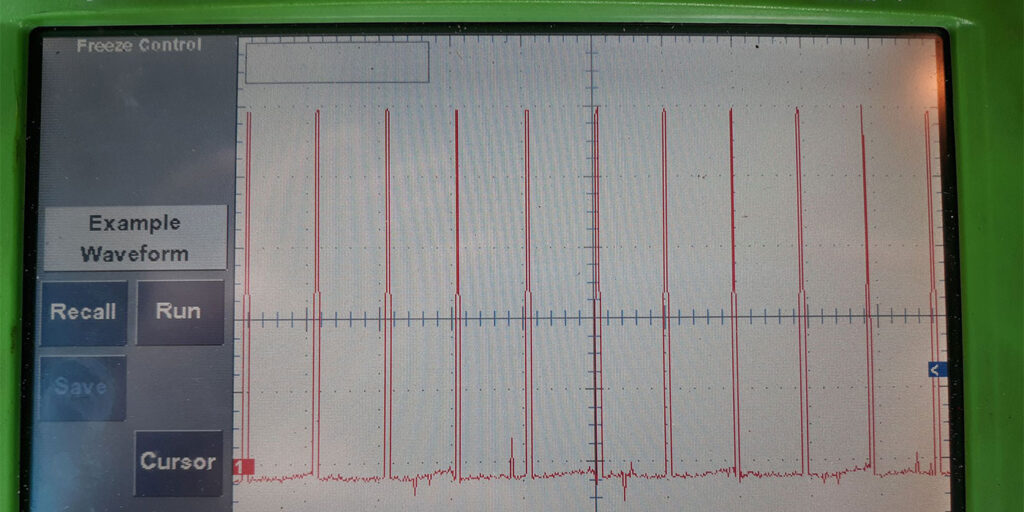

At idle the crank signal looks fine (Figure 1), but also the vehicle runs fine and sets no codes at idle.

When raising the RPM to the point of issue, the crank signal gains one extra pulse that is not evenly spaced with the rest (Figure 2).

So, the code is misleading as it is not a loss of CMP or CKP but a correlation problem. The odd thing is this extra pulse is not random. It occurs once every engine revolution. This indicates that it cannot be an intermittent electrical issue but must be a mechanical problem with the crank trigger wheel.

On this vehicle the trigger wheel is the flex plate. By removing the converter shield, a visual inspection was preformed and revealed a crack in the flex plate (Figure 3).

The crack must have been flexing open at speeds above idle and triggering the sensor. I bought a used flex plate from a local salvage yard for $8.

After replacement, all symptoms disappear, vehicle runs and drives well and sets no codes. When replacing the flex plate, I was surprised to see that externally the transmission case was clean and there were no leaks. I would have expected that a 23-year-old 4×4 truck with 283,000 miles would have mud, dirt and oil all over the transmission. I also noticed a sticker with a build date code on the converter: It was built in 2016. Since the fluid is clean and the transmission case is externally clean, I discovered that the transmission was rebuilt at that time. It seems that this rebuilt transmission was an attempt to resolve the late harsh shift complaint by someone who never saw the cracked flex plate.