Today I found myself working on a 2008 Chevy Silverado with a 4L60E transmission that wasn’t shifting correctly and whose speedometer was jumping around. After a short drive I was able to confirm the customer’s concern that the transmission had an erratic shift. I have seen faulty alternators that cause erratic speedometers, so I did a charging system analysis. The alternator was charging properly, and the AC ripple was normal.

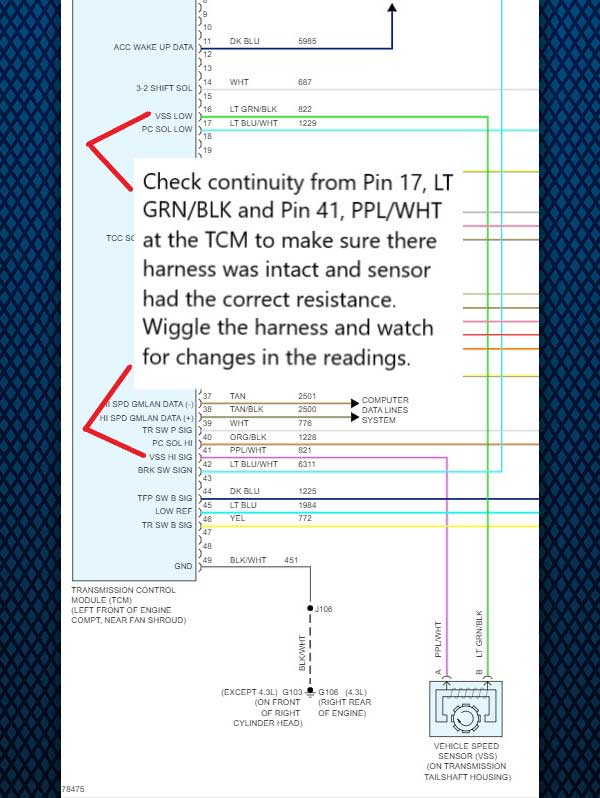

As I drove the vehicle, I could see that the speedometer and the data from the scan tool did in fact match. I also noted that they both seemed to drop in and out at the same time, so my first thought was to look for a bad wire or sensor issue. (See Figure 1).

I was hoping to visually find a wire chaffed or touching a ground, but I had no such luck. After checking the wiring and sensor, the results showed no open circuits and no short to ground. The sensor’s resistance should be between 1,377 and 3,355Ω. The sensor checked at 2180Ω, so it was within range.

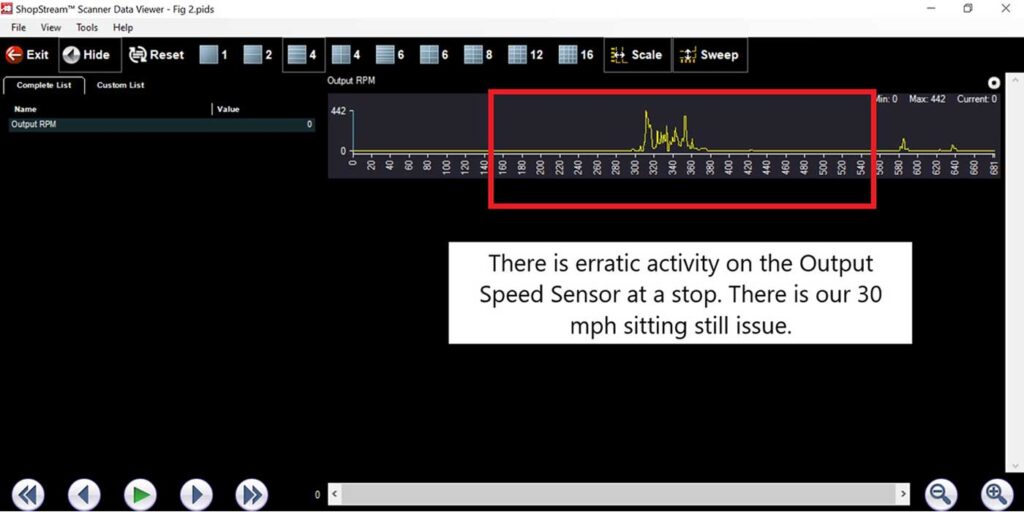

OK, not the results I was hoping for. At this point I was thinking that it could be in the PCM, so I put the scanner back on the vehicle and dove in a little deeper. Now that I had it connected to the scan tool, I was still having issues with the speedometer and the erratic shifting. I grabbed a screen shot of the Output Speed Sensor (OSS) with the vehicle stationary. There was activity showing on the sensor, albeit erratic activity. (See Figure 2).

I placed the truck on a lift with the tires just off the ground, running it in gear while monitoring the OSS signal. I was simultaneously performing a wiggle test at the PCM. There was no change moving wires or connectors at the PCM. It had been running about five minutes at this point. I stopped the wheels, shifted the transmission into park and noticed that I again had a signal while there were no tires spinning. The speedometer displayed 30 MPH in park. I unplugged the sensor, and it was still showing 30 MPH. It was beginning to look like I was dealing with the possibility of a faulty PCM.

In the process of removing the PCM, I placed a fender cover over the fender. Suddenly, there was no issue with speedometer, and now everything was working correctly. What was going on? All I did was put a fender cover on!

Read more stories in our R&R Tech series here.

I wiggled and pulled on the harness again and still was not able to duplicate the problem. I took all my equipment off and it was still working correctly. I took the vehicle for a long test drive and still nothing; the transmission was shifting correctly, and speedometer was working normally.

I took a break and about an hour later I was able to get back to this truck. After a long road test there were still no apparent issues. I thought I must have disturbed something and now wouldn’t be able to duplicate the issue further for testing. But hey, that doesn’t happen in the auto repair world very often now, does it?

I decided to clean up the wiring around the transmission and install some new wire loom covering, because as you probably know, they just crumble and fall apart on a lot of these older trucks. (See Figure 3).

After getting the loom on and the wires taped and secured at the transmission, I was moving the truck out of the bay. At that moment, it started acting up. Once again, the speedometer was reading 30 MPH. On the road test, the transmission had harsh engagements. I raised the hood for another look and to wiggle the PCM connector and wire harness. There was no change.

By now I was again thinking that the PCM is intermittently bad. As I was moving stuff around, my drop light fell on the engine wire harness and the problem went away. My focus was now directly on the area of the harness in question.

My light had fallen on the wire harness that runs along the valve cover, and this was the harness I needed to look at more closely. I wiggled the harness and this time the signal became erratic. I was looking for damage or a place that had rubbed through, and I found nothing. As I was moving the harness, I did notice that the spark plug wires were recently replaced and were wrapped around and laying on the wire harness. I rerouted the spark plug wires away from the wire harness and the issue went away. While I was there, I put new wire loom covering on the harness because the old loom was deteriorated. I wiggle tested the harness again and drove the vehicle a few more times. No more erratic speedometer and the transmission shifted smoothly.

It seems that we see more and more transmission concerns that are not caused by the transmission itself. With so many sensitive electronics involved with the control and sensing aspects driving the transmission, it opens these systems up to outside interference that can adversely affect the function. In this case, a clue could have been that the speedometer was erratic only with the engine running. The transmission control system was picking up inductive voltage from the misrouted spark plug wires. As they say, hindsight is 20/20. Perseverance and a little luck got the issue resolved.