Tech to Tech

- Subject: Using the correct tool to find the root cause

- Vehicle Applications: 2002 Jeep Wrangler, 1972 Chevy El Camino, Dodge Neon, 1993 Ford Mustang

- Essential Reading: Diagnostician

- Author: Brian Manley

Having the right tools can make all the difference

I have been in this business a long time, and I still relish the feeling when I find the fault and fix the car. The root cause is the critter I’m always on the prowl for, and I will use any weapon I can find to bag that beast. That often means extra hours and every resource in my shop; however, I have been fortunate lately to catch some interesting issues fairly quickly by using the correct tool. Following are some situations I’ve encountered recently. Which tool would you use to correct them?

2002 Jeep Wrangler: hard to start cold

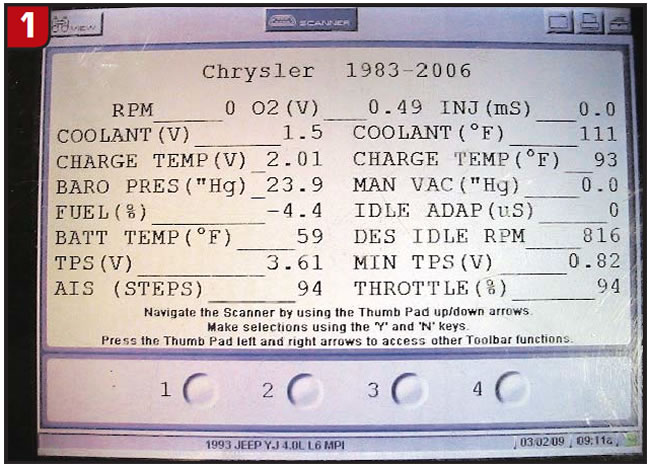

This Jeep ran fairly well and did not fail to start for me. The customer had regular maintenance performed so the vehicle did not seem abused. During the customer interview, he mentioned that the colder the ambient temperatures, the longer the engine cranked before it fired up. What would you do first? I grabbed my scan tool and pulled the key-on, engine-off screen shot of the scan data in Figure 1.

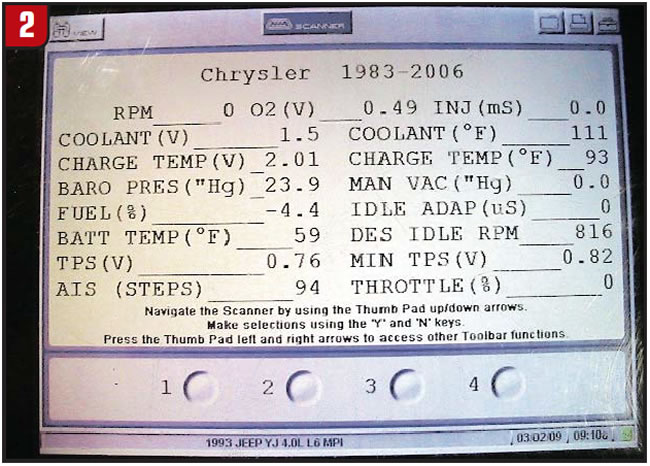

Can you spot a possible root cause by scrutinizing the data? I know it’s a little like taking the ASE Advanced Engine Performance Test, but many of you will spot the root cause quickly. If you say “TPS” – throttle-position sensor – you are right! I found that the TPS was stuck at 3.61 volts, and the P0123 code (TPS voltage high) will set only when the voltage remains above 4.5 volts for 3.2 seconds. I don’t know if 3.61 volts will trigger a “clear flood” mode condition – where the fuel injectors are turned “off” by pressing the accelerator pedal to the floor – but I knew it was sending the powertrain control module (PCM) bad information. Replacing the TPS fixed the customer concern and gave me the “right” closed-throttle screen shot (Figure 2).

1972 Chevy El Camino: broken-bolt nightmare

This classic truck came rolling in on the hook with a “starting” issue. While attempting to crank this small-block over, I heard the telltale sound of a starter that was not right with its ring gear. Once I had the truck in the air, I could see evidence of a futile attempt to repair a stripped starter-bolt hole. Figure 3 reveals the block that had been cut away and a new starter-mounting stud welded in its place. Unfortunately, there wasn’t enough mounting surface left on the block for the starter to mount flush with, and any starter installation would be temporary at best.

What would you do in this situation? Having wandered down this path in the past, I recommended another engine block or a used engine; anything to restore the original bolt holes.

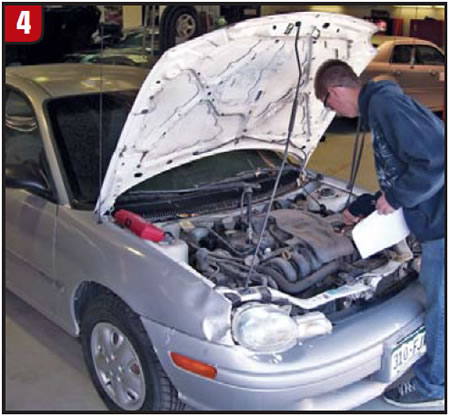

Dodge Neon: no start

This vehicle (Figure 4) came to us with the help of a flatbed, along with a “no-start” concern.

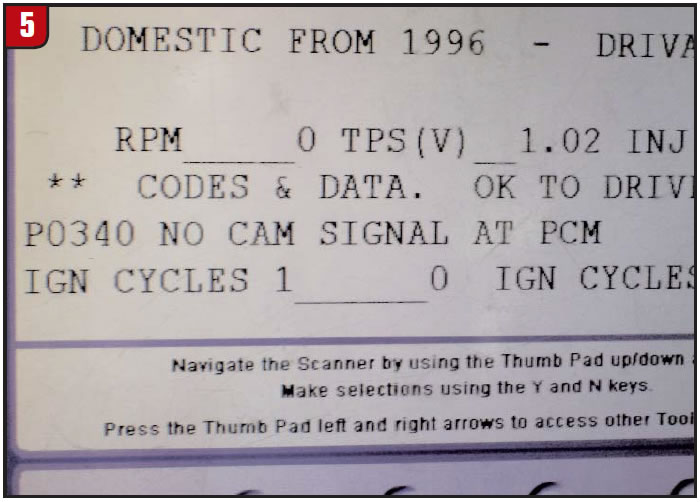

The engine cranked over nicely but never wanted to fire. What would be your first step? Once more, I decided to tap into the PCM to see how it was feeling. Our scan tool found the following trouble code (P0340 [Figure 5]):

Our information system gave us the following code-setting criteria: “Camshaft position (CMP) sensor signal is monitored when the engine is cranking or running. Code will set when PCM senses five seconds or 2.5 engine revolutions have passed with crankshaft position (CKP) signal present, but no signal from CMP.”

What is your next step? We decided to see why the CMP had stopped seeing any action, so we physically checked for rotation of the camshaft, and we found none; the timing belt had stripped, and the PCM was doing the best it could to let us know!

1993 Ford Mustang: dies intermittently

OK – I cringe when I hear the “I” word, too. Intermittent issues can be some of the most challenging, and it takes diligence to nail the root cause. Where do we begin? Well, I attempted to verify the customer concern, which took longer than I had hoped. This vehicle became “the car you start and run outside the bay and listen to while you work on other cars.” This car started, ran, drove and never had a hiccup until day three, and then it would stall while running after about 10 minutes. When it failed to start, it produced a nice spark while cranking; however, we found that the fuel-pressure drop corresponded with the stalling condition. The frustrating part was that it would restart almost immediately, so our window of opportunity to catch a failed component was small. Through a systematic process of back-probing the fuel-pump connector, inertia fuel-shutoff switch and constant-control module (CCM) – which contains, among other things, the fuel-pump relay – we caught the fuel-pump relay in the CCM not sending power to the fuel pump. After verifying that the module had all the other inputs it needed (powers and grounds) to be happy, we condemned the CCM. A new module (Figure 6) repaired the customer concern.

The conclusion to these four relatively “easy” fixes? Sometimes experience is a great friend to have, and it can help you decide what to do first to save time. When a vehicle has a PCM, it makes sense to plug it in and see what it’s thinking, and what it has recorded for you. If a starter motor sounds “weird,” it is usually caused by the pinion-to-ring-gear relationship. Finally, if you suspect that an electronic control module is the cause of a no-spark or a no-fuel condition, the use of a hair dryer to apply heat can cause it to fail more often, as it did for our Ford Mustang no-start.

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. He can be reached at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.